Technologies to cultivate the future

Further promotion of research and development of embroidery machines to keep leading the industry

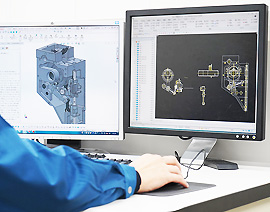

In order to meet the needs of our customers, we will strive to improve our development environment by introducing state-of-the-art equipment in order to develop high-productivity embroidery machines that produce high-quality embroidery products.

In an attempt to clear up the secret of “sewing,” once mostly dependent on the hunch and experience of skilled artisans, we have visualized the “sewing” process with a high-speed camera and scientifically analyzed it.

Also, in order to achieve both higher speed and lower vibration, which actually conflict with each other, we have introduced the latest type of a simulator. In addition, we have set up endurance test equipment that can perform completely unattended operation around the clock.

In this controlled environment with the latest equipment, we are carrying on our R&D activities.

In order to quickly utilize the most-up-to-date information from the world for product making

Not only with the group companies at home and abroad but also with research institutes and companies of different industries,

we have close alliances in order to actively promote joint R&D and technical links, as well as to share the latest information.

Pioneering the future with solid technology and excellent development capabilities

Based on the technology of sewing threads freely, the technical capabilities accumulated at TAJIMA for many years are toward not only the apparel field, but also new technologies for industrial fields by sewing special materials to various fabrics such as widely applied to industrial applications.

Embroidery technology is used for heated car seats to fix a heater wire for heat generation.

It is also applied to the punching processing using punches instead of needles and the creation of carbon preforms sewing carbon fibers in any direction.

Industrial embroidery technology is a little-known field, so it can be expected beyond imagination.

It is attracting attention in IT and wearable computing market, and opens up possibilities in a wide range of fields such as automobiles, aerospace, architecture, robots, and medical care.

Pioneering the future of industry to the future of living with “sewing” technology—

We want to be like that.

Global expansion

TAJIMA has provided over 3,000 embroidery machine models to our customers in over 130 countries around the world.

TAJIMA has been building trust with customers since its establishment in 1944 with high technology and attentive service.

Over 3,000 embroidery machines have been sent to more than 130 countries around the world.

We succeeded in establishing a global network outside of Japan, centering on three local production bases in Shanghai, France, and the United States.

In addition, we have distribution bases in Europe and Asia.

In the meantime, we have been focusing on “creating good products which can be used in the world by making ingenuity and enabling things that could not be done before.

We will continue to provide it with the best service. “

This thought has been handed down to the next generation and is being used to make even better products.

Overseas office

Sales and technical service of “TAJIMA” brand electronic embroidery machines and relative equipment.

Customer support

TAJIMA Responsibly Responds One Step Ahead of Customer Expectations

Making the most of our long term accumulation of know-how and network, we, TAJIMA, provide them with our most appropriate system through our activities using all aspects of our activities ranging from sales to maintenance and after-sale service, including the provision of embroidery techniques and trendy information.

Delivery of Tajima embroidery machine

This is a scene where a TAJIMA embroidery machine was brought to a customer’s site in Salento in southern Italy. It is not uncommon to install embroidery machines on the second floor or higher, and the embroidery machine is delivered hanged by a large crane.

Embroidery machine is brought in with disassembled, but there is no deficiencies in performance because our technician assembles it carefully.

In some cases, although they are repaired later, holes are made in walls or an entrance is broken to bring in a machine.

Once the delivery is completed, our technician levels the machine and install some parts first and then do a trial sewing and a training for the operator.

Since Follow-up service is also provided, you can use it with confidence.