OUR STRENGTH.

Our embroidery

techniques

have continued to evolve

with the times.

SERVICES

-

SEWING

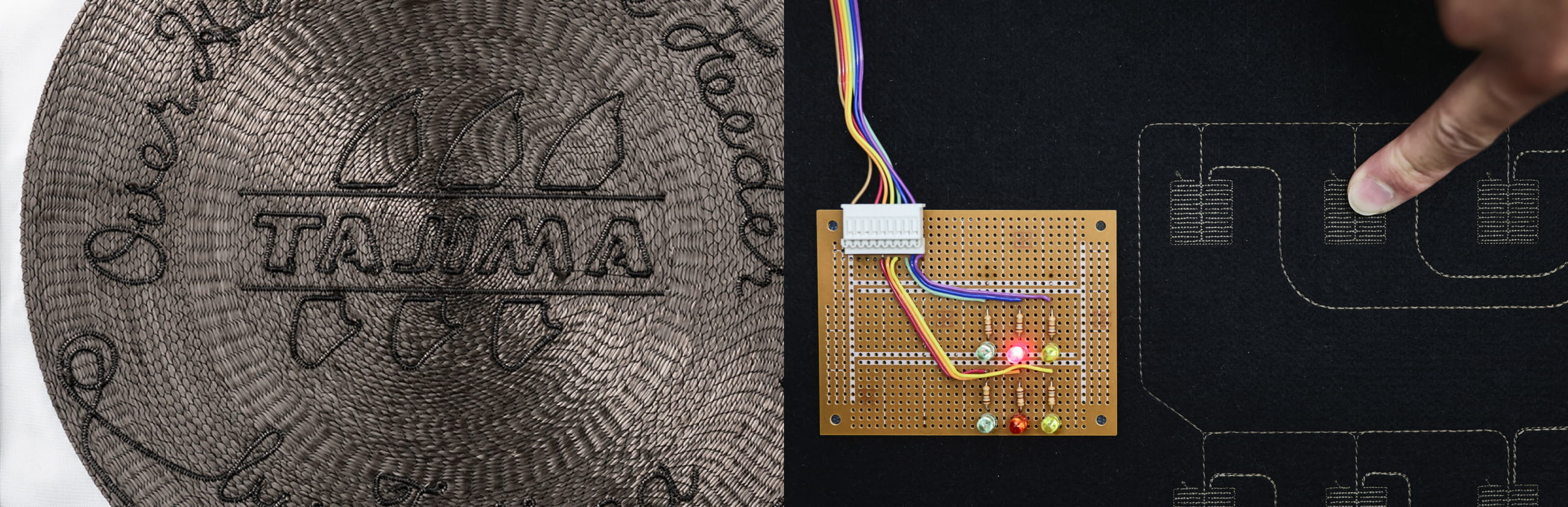

TECHNIQUESDeep understanding of

stitch formation -

FRAME CONTROL

TECHNOLOGYControl technology to move

the frame accurately and at high speed

EMBROIDERY TECHNOLOGY

-

EXPLOITATION

EMBROIDERYBUSINESS

-

EXPANSION

SEWINGBUSINESS

-

DEVELOPMENT

TIPBUSINESS

We will create new markets and provide greater value to society by further deepening our core embroidery business and expanding into other fields.

EMBROIDERY BUSINESS

EXPLOITATION

Passing on the technology and knowledge of "sewing" to the next generation with state-of-the-art technology.

TAJIMA's core technologies have been honed since our founding.

Unconstrained by conventional ideas, we solve problems faced by society and our customers from both hardware and software perspectives. As a pioneer in the embroidery industry, we will continue to challenge the possibilities of embroidery and the creation of new value.

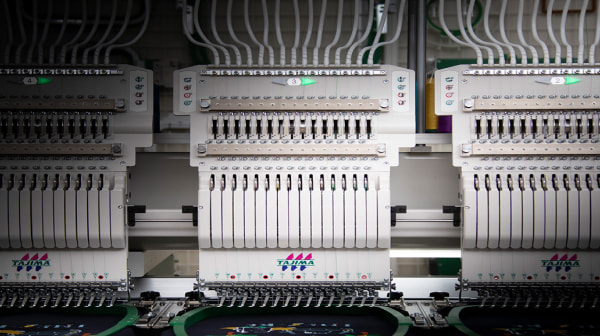

- Manufacture and sale of embroidery machines, software and related equipment

- Provision of services

-

TMEZ

The world's first AI-equipped embroidery machine to support production sites!

AI supports the production of high-quality embroidery. State-of-the-art embroidery machine that is not dependent upon operator experience.

-

SAI

Compact embroidery machine to accelerate personalization

While easily reproducing professional finishing, this compact machine works great in limited space. It makes embroidery more accessible in any setting, including hobbies and in the store.

SEWING BUSINESS

EXPANSION

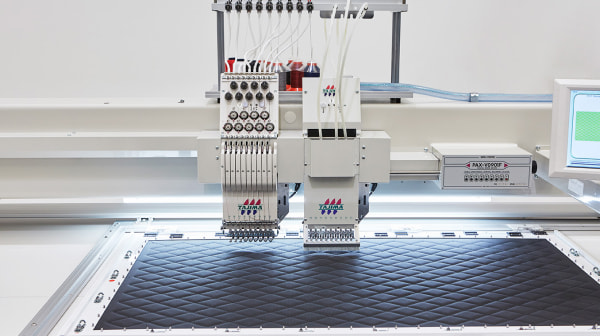

More beauty, more freedom. Fusion of beauty and function in various scenes.

In addition to conventional embroidery, beautiful quilting is achieved through high-precision hole perforating and multicolor sewing. Tajima's technology realizes beauty and functionality that transcends industries such as mobility and interior design, as well as ventilation in the automotive industry.

- Manufacture and sale of hole perforating, multi-color sewing and multi-color embroidery equipment for car seats, leather goods, etc.

- Provision of services

-

PAX

Perforate, sew and embroider - all within this one machine.

This single machine handles perforating, sewing, and embroidery. Since there is only one processing data, no discrepancies occur and corrections can be easily made (ideal for policy development applications). Compatible with all materials, including genuine leather, synthetic leather, and vegan leather.

TIP BUSINESS

DEVELOPMENT

Bringing our accumulated "sewing" technology to the new world.

We are expanding our technology for freely sewing and fastening materials into a wide variety of fields. We can freely orient and sew carbon fibers, optical fibers, electric heating wires, signal wires, and other materials.

We will establish new values for the Tajima Group by thinking freely and without being bound by industry norms.

- Processing of composite materials such as fiber-reinforced resin, manufacturing and sales of equipment

- Provision of services

-

TCWM

Enables production of high precision preforms with low scrap rate.

The material can be sewn in any shape and orientation, maximizing the rigidity and strength of the carbon fiber.

Compared to conventional process, this is more sustainable and cost-effective, with less loss of material.