Tajima to Launch New AI Embroidery Machines as TMEZ-KC Series

Tajima Industries Co., Ltd. (based in Nagoya, Japan), a leading embroidery machine manufacturer striving for automation of embroidery, production network management, and promotion of smart embroidery businesses, is proud to announce the launch of new embroidery machines on January 22, 2021, as the brand-new “TMEZ-KC Series” models, equipped with the “i-TM” function for automating the embroidery finish.

While society has been going through great technological progressions like digitization in recent years, the apparel-manufacturing industry has come to face emerging issues associated with the labor shortage caused by the global COVID-19 outbreak. In such circumstances, the company is centering its corporate focus around automation of the machine embroidery production process by equipping machines with its proprietary AI technology “i-TM,” designed to automate the embroidery finish, as a solution to the manufacturing labor shortage.

TMEZ-KC Product page:https://www.tajima.com/product/tmez-kc/

Tajima’s Original AI Technology “i-TM”

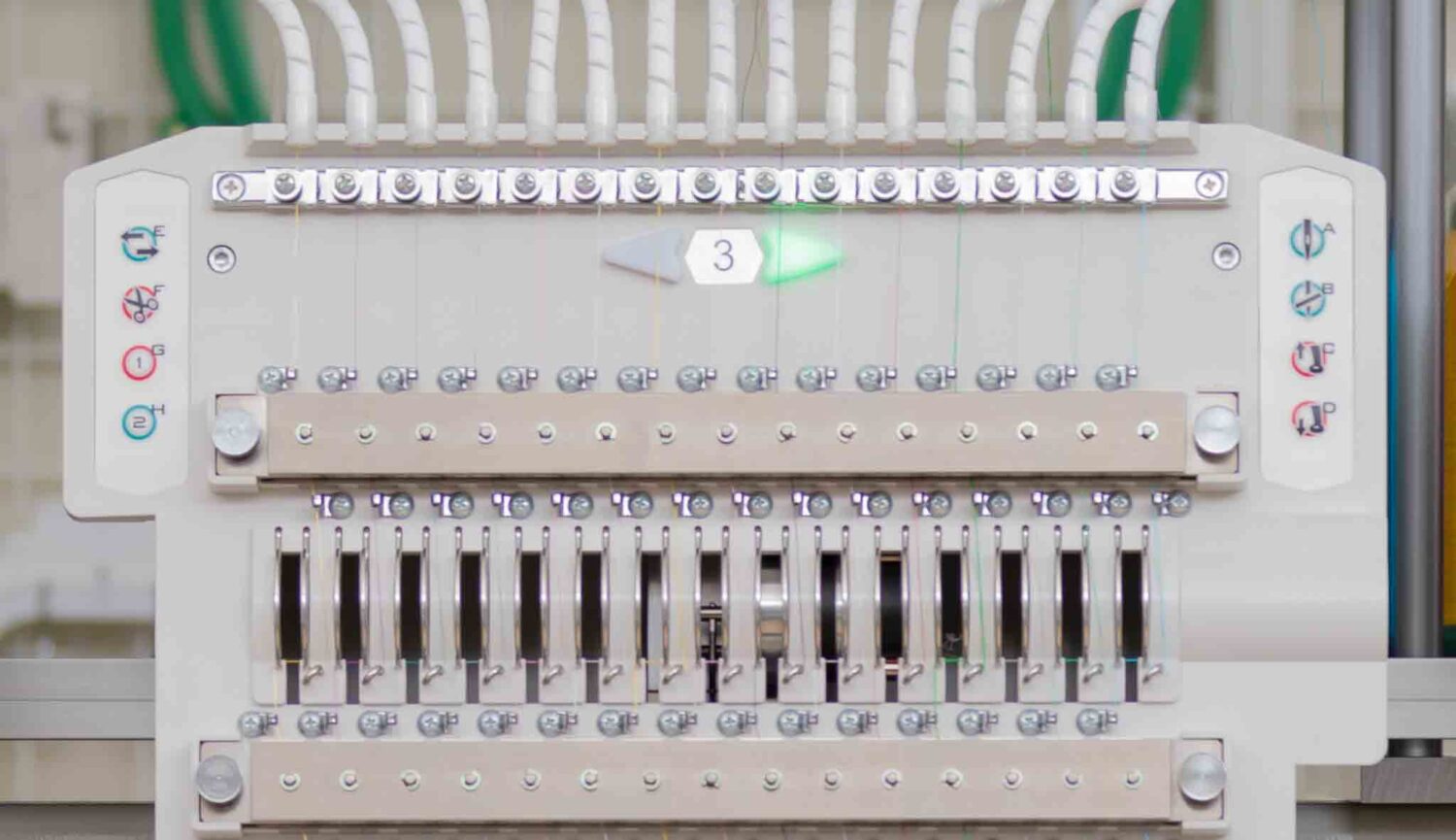

“i-TM” stands for “Intelligent Thread Management.” In machine embroidery, patterns may be stitched in all different directions and the stitch length may vary even in a single design, making machine embroidery one of the most difficult types of sewing. The company has successfully algorithmized the embroidery finish patterns acquired through many years of experience to produce “i-TM.” This AI technology analyzes the stitch-by-stitch sewing direction and fabric thickness to compute the appropriate amount of upper thread feed for the next stitch and makes proper adjustments to stitches so that the embroidery finish that is considered to be “good” can be achieved in a stable manner.

Advantages of “i-TM” at Machine Embroidery Factories

Shorter Test Sewing Time

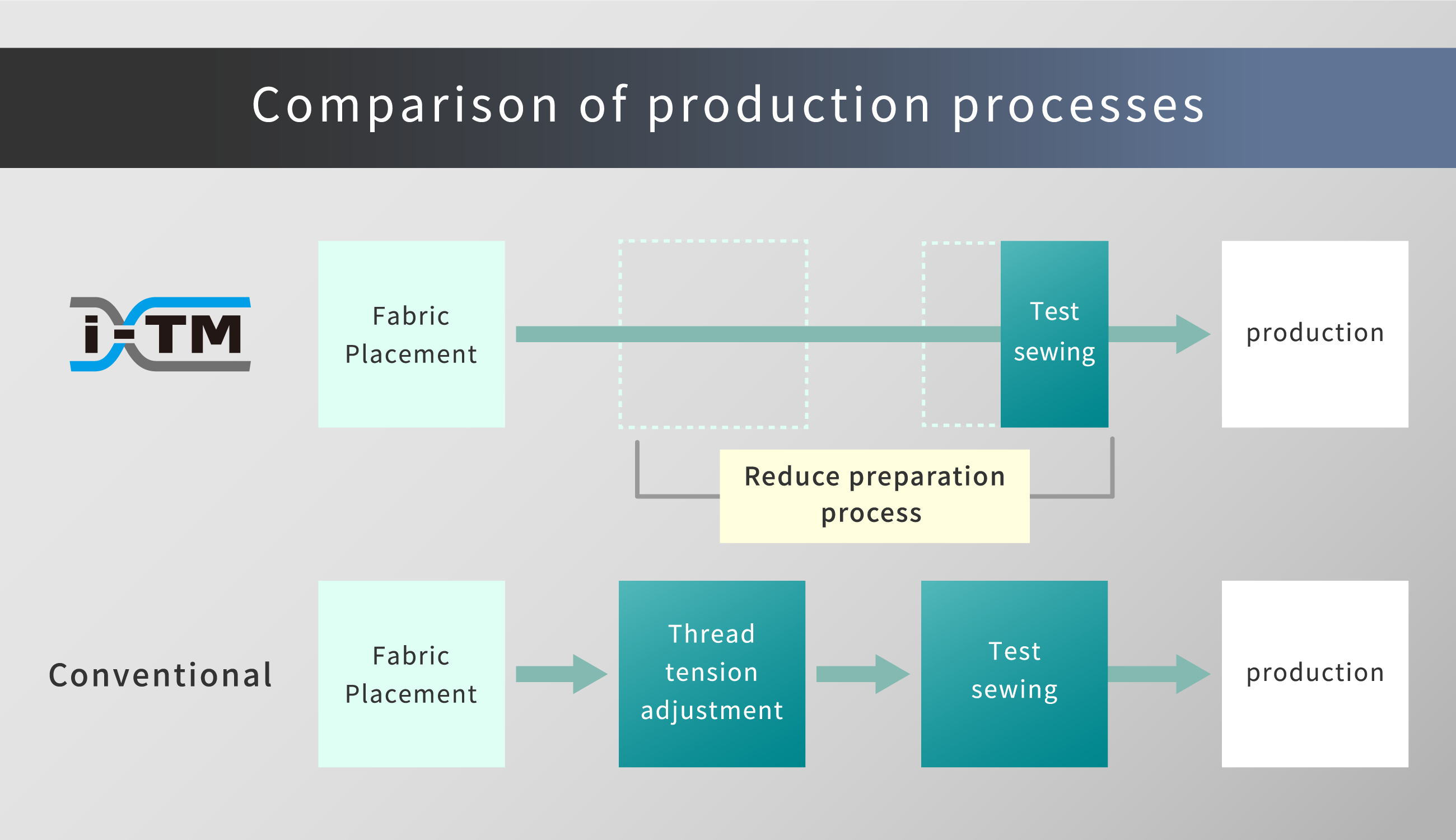

While most operators using conventional embroidery machines perform sewing tests to adjust the thread tension prior to actual production, i-TM-installed machines require much less time for test sewing in the preparatory process, allowing operators to use the time saved for production activities. The i-TM models are especially suitable for embroidering on ready-made products with mixed levels of fabric thickness and elasticity, such as caps, T-shirts, patches, shoes and socks.

Reduced Manufacturing Defects and Losses

The most frequent losses observed at machine embroidery factories are the products that fail in the quality inspection due to an insufficient embroidery finish. The i-TM models automatically adjust the embroidery finish to achieve good results in a stable manner, thus contributing to reduction of manufacturing losses.

New Operators Readily Set to Work

Operators with experience-based skills play a crucial role in the conventional practice of upper thread tension adjustment to varying thread types. With “i-TM,” on the other hand, operators’ tasks are eased as the thread tension does not need to be adjusted manually, saving managers the time for training operators.

Beautiful Finish with Various Thread Types

“i-TM” incorporates the stitching techniques that Tajima has accumulated over decades and produces a beautiful embroidery finish by tightening the thread firmly for linear running stitches while providing soft sewing for zig-zag satin stitches.