Tajima Industries Ltd. (Headquarters: Aichi, JAPAN; President: Hidetoshi Kojima, hereinafter “Tajima”) is pleased to announce that its gradient embroidery has been adopted for the flagship coupe, the LEXUS LC Special Edition “PINNACLE.”

The embroidery applied to the passenger-side instrument panel embodies a fusion of LEXUS’s design philosophy and Tajima’s advanced craftsmanship.

With layers of delicate threads, this creation brings a new sense of beauty and elegance to the realm of mobility.

The flagship coupe LEXUS LC, presented in its special edition “PINNACLE,” features gradient embroidery within its interior.

About the Gradient Embroidery

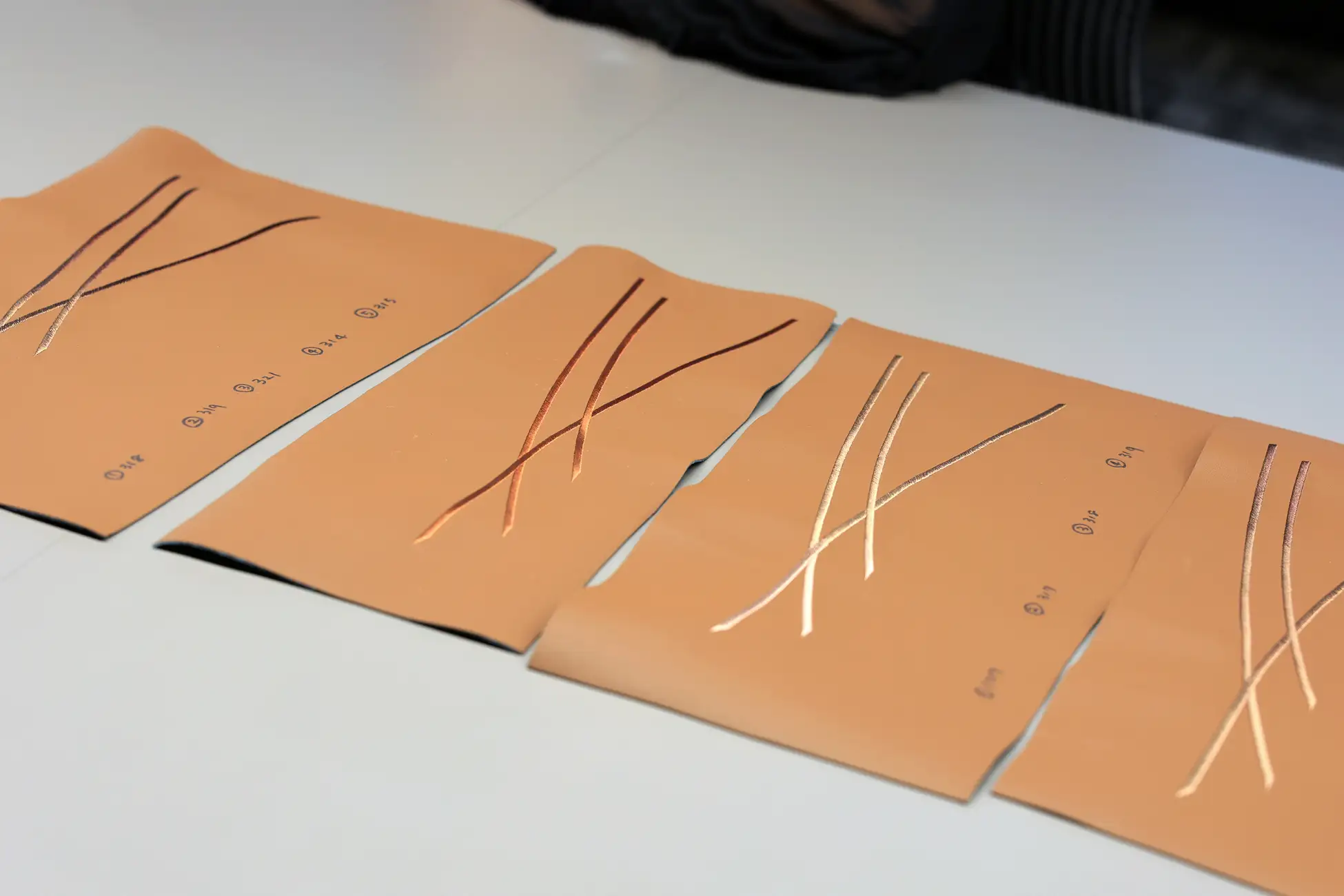

The embroidery was completed through close collaboration with the designers, expressing a gradient inspired by natural scenery.

Pursuing “Art × Science” Beyond Industry Boundaries

Over the course of approximately two years, the teams refined the design from both aesthetic and quality perspectives. Even under the demanding conditions unique to automobiles—such as weather resistance and durability tests—the embroidery achieved delicate expression while maintaining the highest standards.

By merging the expertise and philosophies cultivated by both LEXUS and Tajima, the project realized a form of innovation that transcends industry boundaries, balancing artistry with stability.

For more details on the development background and in-depth discussions with the designers, please visit the interview article on Tajima Group’s web magazine “TAJIMAG.”

▼ Read the TAJIMAG interview article:

The LEXUS LC500 / LC500 Convertible Special Edition “PINNACLE” features Tajima’s embroidery technology.

AI-Powered Embroidery Machine Achieving Consistent Quality and Enhanced Productivity

Supporting the gradient embroidery in this project is Tajima’s proprietary AI-driven embroidery machine. It faithfully reproduces even the most delicate color transitions with remarkable stability and can handle fabrics of different textures using a single embroidery data file.

With i-TM and DCP technologies, optimal adjustments are automatically performed for each needle, simultaneously achieving uniform quality and improved production efficiency. This technology combines the precision required to faithfully express a designer’s intent with the reliability to meet strict automotive standards.

*i-TM (Intelligent Thread Management): Tajima’s proprietary AI technology that automatically optimizes upper thread tension according to the material, based on measurements obtained by DCP.

*DCP (Digitally Controlled Presser Foot): Measures fabric thickness variations within just 0.05 seconds per stitch, automatically adjusting presser-foot pressure to suppress fabric fluttering that can cause skipped stitches.

■Tajima Group

Tajima is a Japanese embroidery machine manufacturer established in 1944. As a leading company in the embroidery machine industry, Tajima developed the industry’s first embroidery machine equipped with AI technology to pursuit finely detailed and beautiful embroidery. In 2022, Tajima also welcomed a prominent Canadian software company into the group. It aims to transform the embroidery business from both hardware and software perspectives. Furthermore, its technology is being deployed and used in a wide range of fields, including the automotive and aerospace industries.

Press Release Page:https://prtimes.jp/main/html/rd/p/000000022.000039898.html