Tajima’s Total Solution

to Support Optimal Supply Chain Construction

Supply chain optimization is a very important issue for brands and companies. These days, it is necessary to construct a supply chain taking into account geopolitical risks and ethical production and consumption. Tajima supports the construction of a supply chain that is optimized for the services and values that customers want to provide.

Tajima employs AI, automation, IoT, and other advanced technologies in providing support to production bases with both hardware and software. With a worldwide sales network of more than 60 companies, customers can receive high-quality services anywhere in the world. From deployment to maintenance and after-sales support, trust us.

Supports optimal production building anywhere in the world

Embroidery of finished products

Cylinder-type machines for embroidering cylindrical items can be used to embroider finished products such as clothing and hats. In addition, some production processes can be located close to the site of consumption. Tajima offers embroidery machines suitable for various uses, from single-head machines to flat type machines.

More about TMEZ-KC

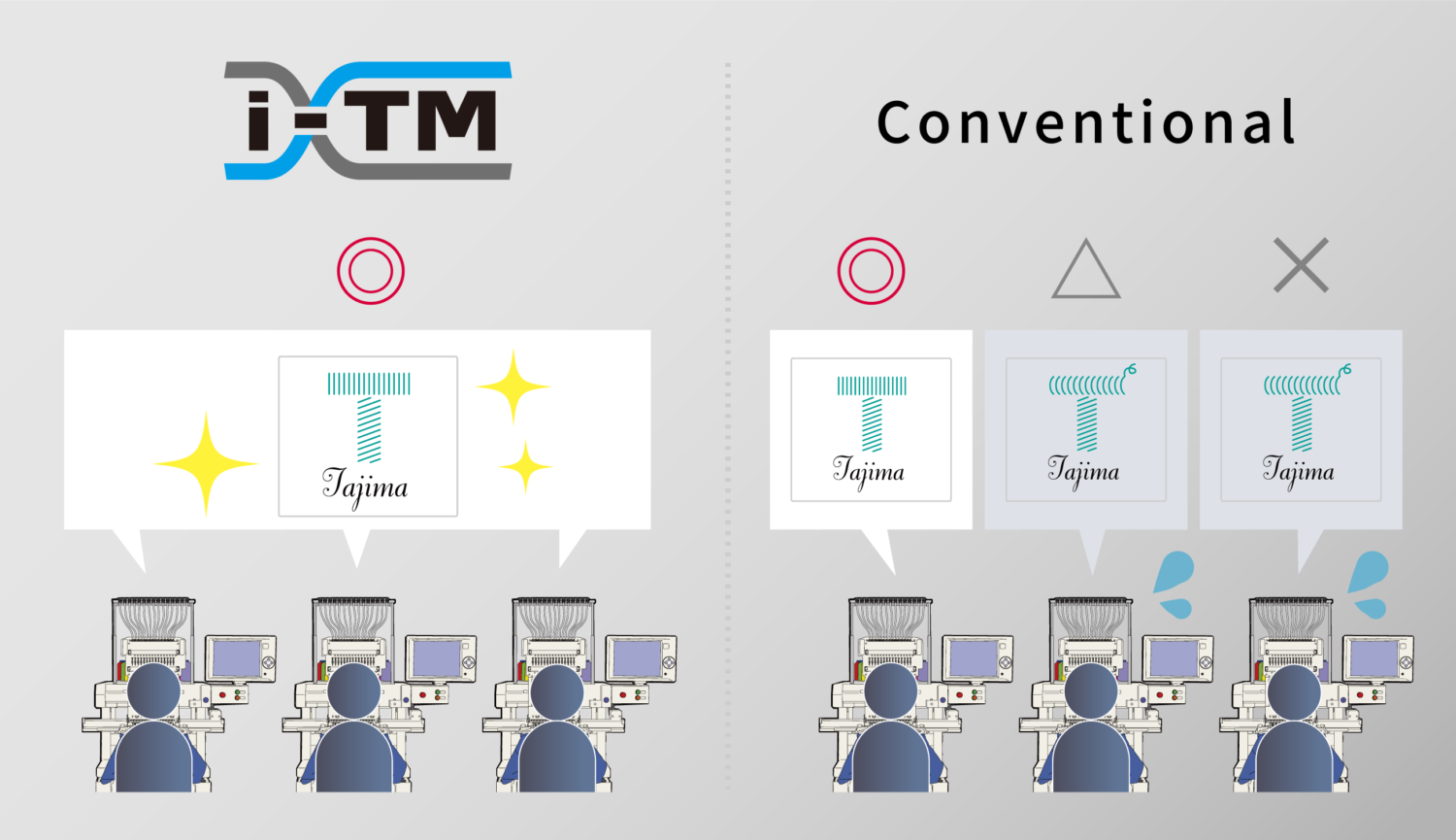

AI-equipped machines that even beginners can operate immediately

“i-TM” uses AI to automatically control needle thread tension adjustment, which has a major effect on the embroidery’s finish. These machines can eliminate differences in quality between operators and consistently provide the highest quality embroidery, even in factories operated by beginners to embroidery.

More about i-TM

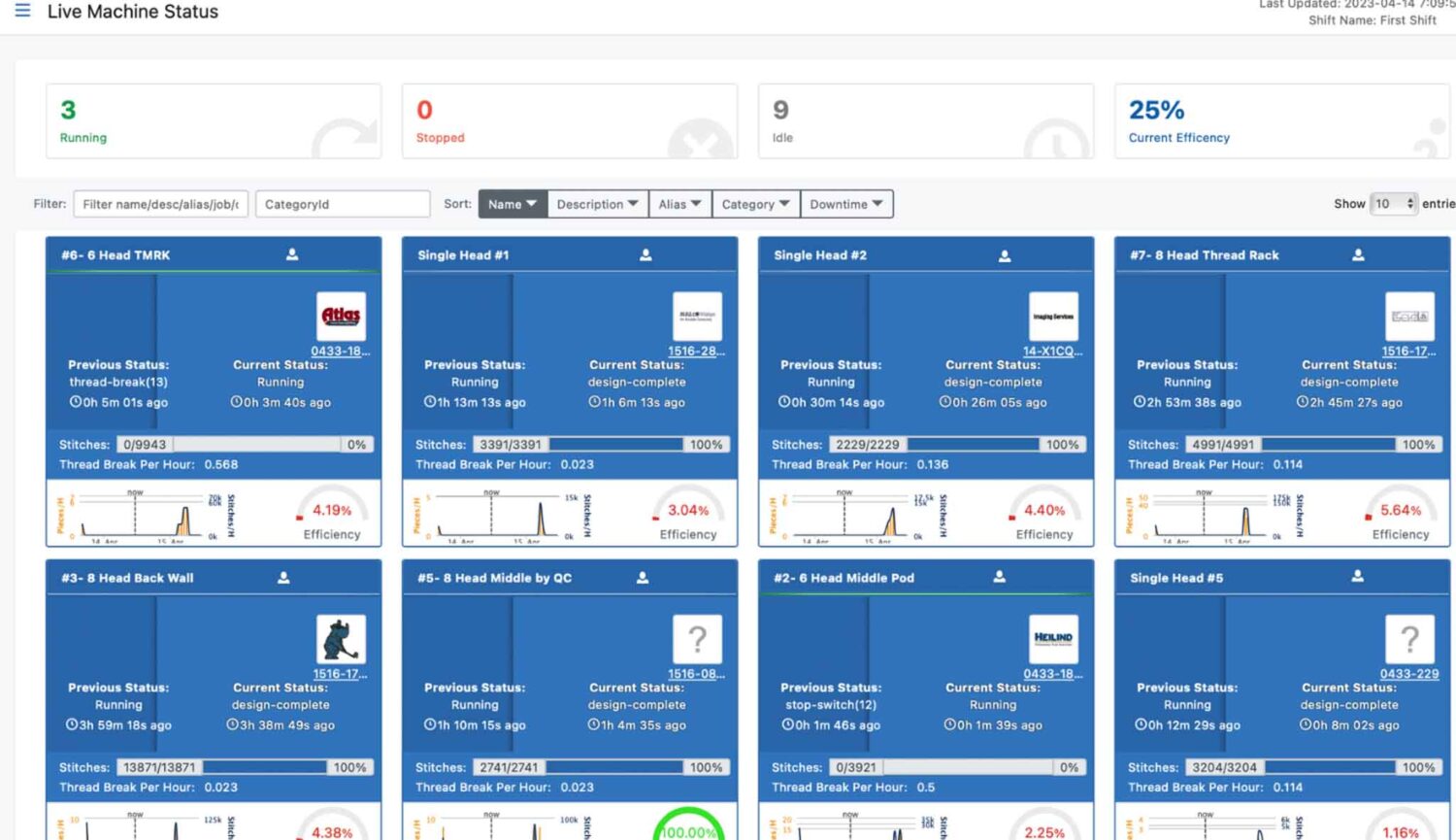

Optimizing factory operations with PulseID

PulseID is an integrated system that handles everything from automatic creation of embroidery data to data transfer, production status, and report creation. Functions such as the ability to check the factory operating status remotely enables more efficient factory operations. The report function included with the system can be used to visualize the operating rate and production volume data for each operator individually, which is useful in improving training and factory operations.

Checks operating status

Data on progress in production for the entire factory and issues with each individual embroidery machine can be collated and checked remotely. Production at multiple locations in different countries can also be centrally managed.

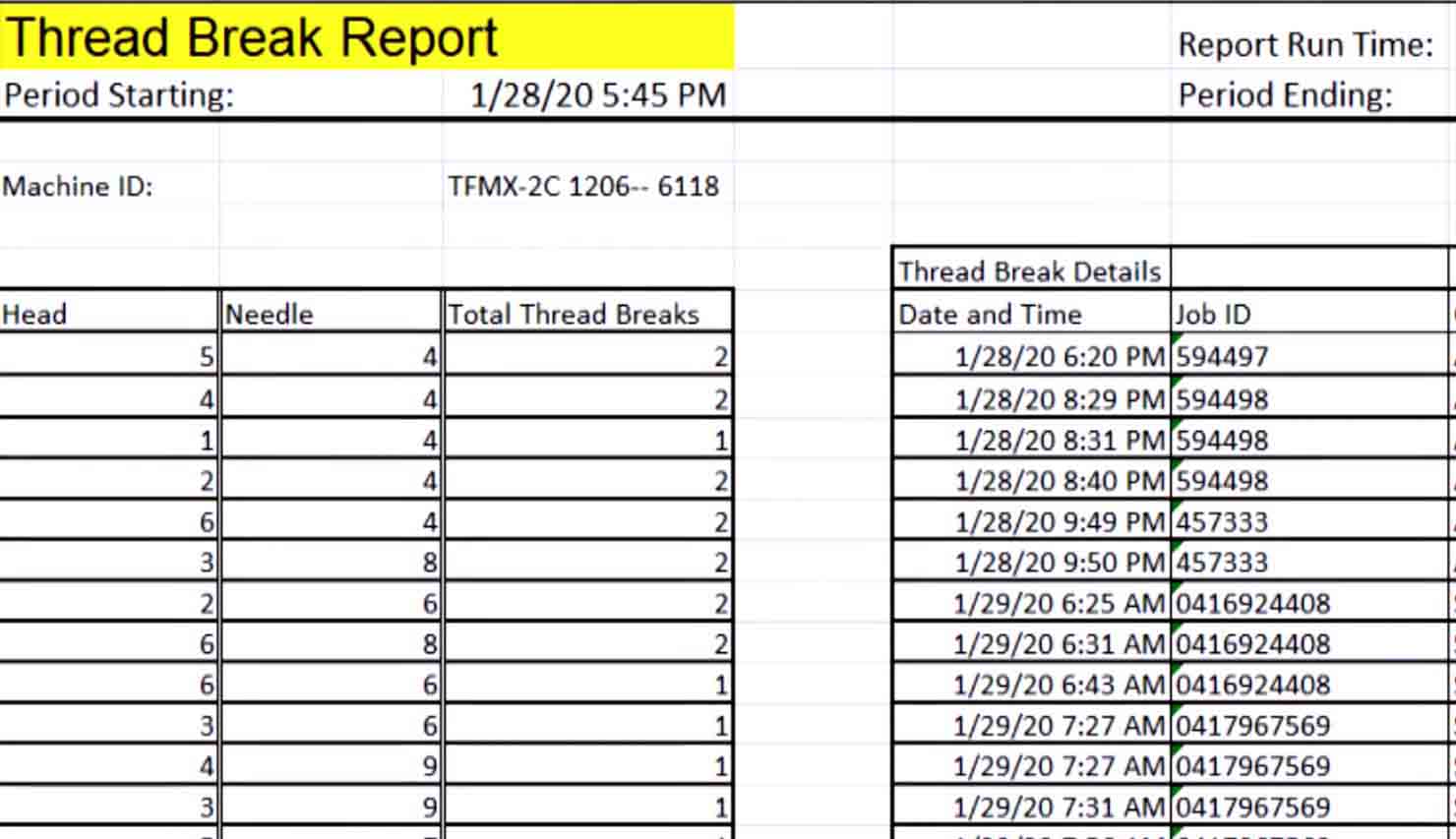

Generates reports automatically

The system automatically creates reports from the created production data. It also can output customized data, a useful feature in confirming progress, calculating payrolls, and other tasks.

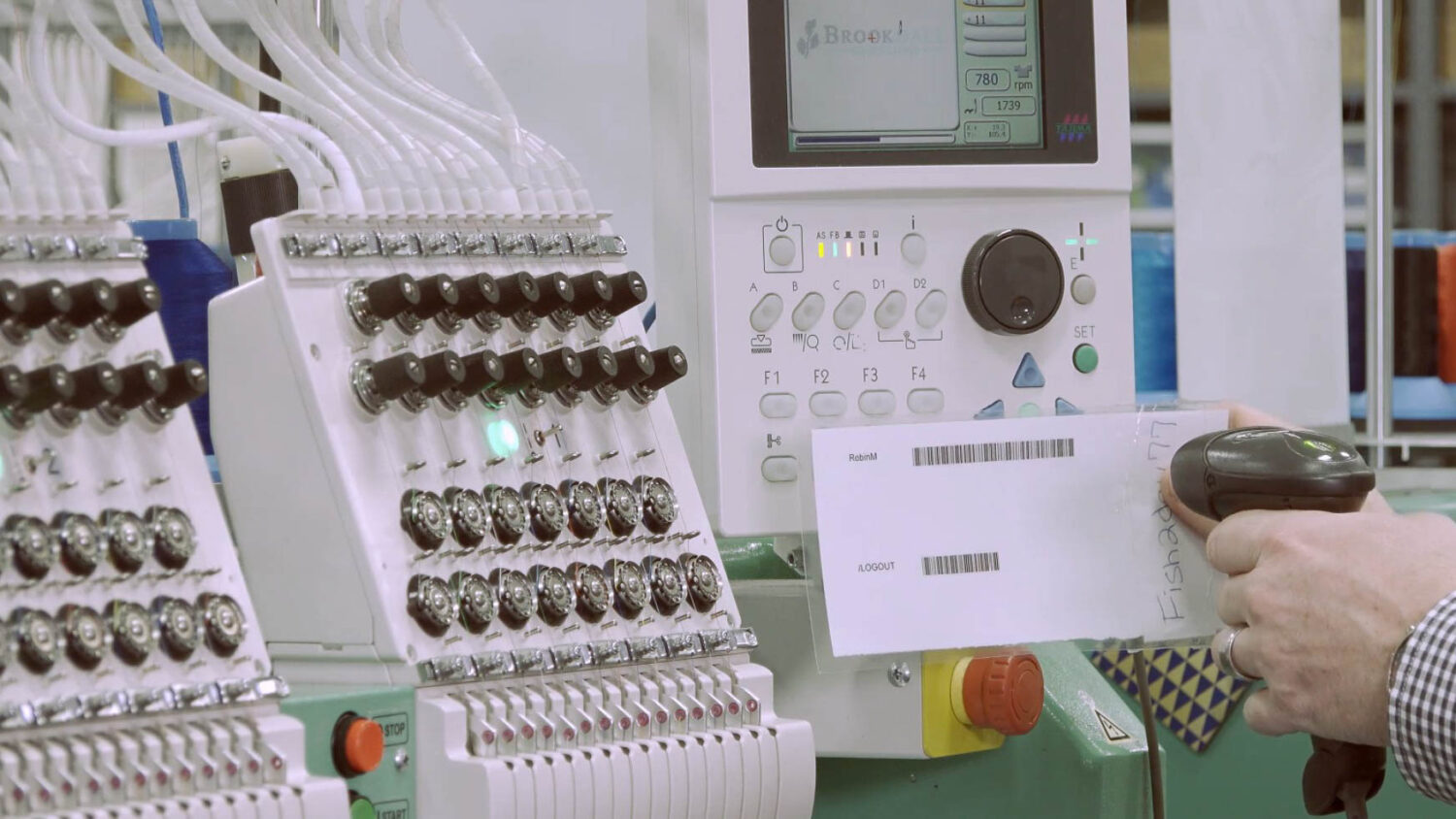

Data is transferred with barcodes

With a single scan, all of the data necessary for production is transferred to the embroidery machine. This reduces the steps of selecting the data and setting the machines while also preventing human errors.

Recommended Products