Challenge yourself to do what you couldn't before. Keep at it, and embroidery will have a bright future.

―interview―

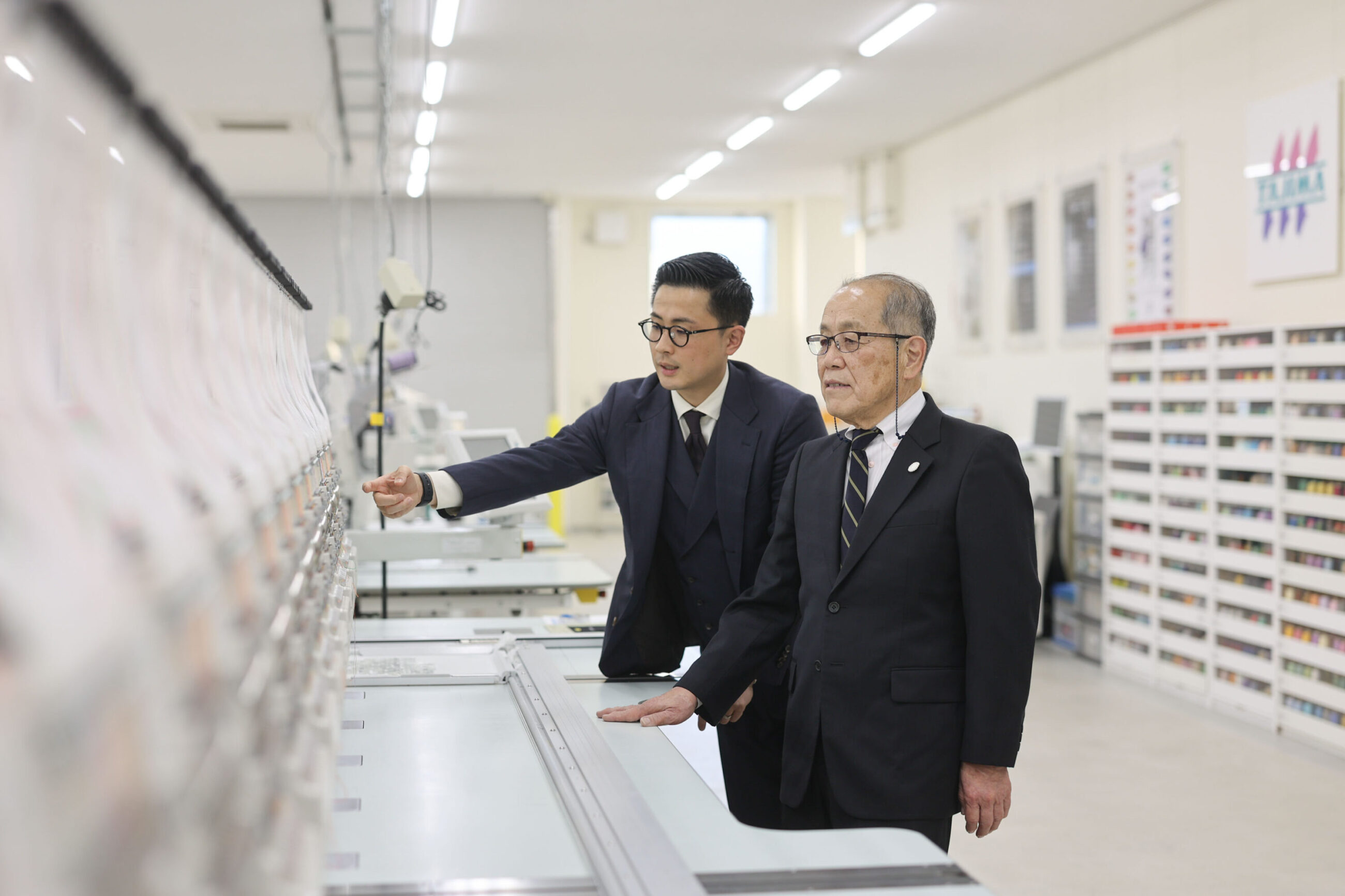

Kasamori Corporation. Representative Director and Chairman: Yasutoshi Kasahara (right)

Tajima Industries Ltd. CEO: Hidetoshi Kojima (left)

This page features Hidetoshi Kojima, Representative Director of the Tajima Group, in conversation with individuals associated with the company. In this edition, we are pleased to have Yasutoshi Kasahara, Chairman of Kasamori Corporation, an embroidery processing company. You’ll definitely want to check out this interview with Chairman Kasahara, who is constantly taking up the challenge of new technology and exploring the potential of embroidery.

Kasamori Corporation

Headquartered in Kiryu City, Gunma Prefecture, this embroidery processing company pioneers new possibilities for embroidery by combining the manufacturing expertise it has developed since the company’s founding in 1877 with cutting-edge technologies. Their embroidery accessory brand “000” (Triple O) launched in 2010 is has garnered attention both in Japan and around the world.

INDEX

Aiming Not for 120 Million, but for 8 Billion

Q: First of all, please tell us what you both think about embroidery’s appeal and potential.

Kojima

Well, first, I believe embroidery itself has a wonderful ability to uplift people’s spirits.

I find it rewarding to be part of a business that involves something so valuable.

Kasahara

It’s true that the appeal of products with or without embroidery are completely different. I think expanding the applications of embroidery to products other than apparel and fabrics can lead to the creation of new markets. For example, embroidering Japanese fusuma sliding doors allows you to create luxurious, one-of-a-kind fusuma. We can also think of many other interesting applications, such as embroidering food.

Even if we can do something with the technology we have now, it simply means anyone can do it. We want to go a step beyond that, take it a little further. If we take up that challenge, I think embroidery has a promising future.

Kojima

Thank you. I think so, too.

Kasahara

Of course, failures are bound to happen. But overcoming failure allows us to see the next success. I think we need to act fast and take that first step. My company has always been like that. First say it out loud. Then go do it.

Kojima

Your company has really taken on that challenge by breaking with conventional wisdom, creating three-dimensional embroidery spheres and other products that would have been unimaginable before, especially for industrial embroidery, and then making it a successful business. (Kasamori Corporation. has been developing the embroidery accessory brand “000” (Triple O) since 2010.)

Kasahara

Yes, indeed. Speaking of the time we created that, we used to have a branch in Indonesia, but we pulled out in 2005. At the time, I thought that from that point on, instead of manufacturing products overseas and shipping them to Japan, we should manufacture products in Japan and aim to sell them abroad. So, we started attending trade shows overseas.

Well, even though we discussed participating in trade shows abroad, we didn’t have any products to show. We’d say, “Hey, we’re going to be at the Paris trade show!” And then we applied for a booth, but we had nothing to exhibit. So, we frantically started working to make something. The day we left for the show, the bus to Narita Airport was scheduled to leave Kiryu at 4 a.m., but we were still working on the product almost to the last minute, until 2:00 or 3:00 a.m.

Kojima

Whoa! You were working on it until that late hour?

Kasahara

That’s right. We continued working away at it for some years, and then in the fourth year, we were approached by a major brand. When I asked them why they came to us, they said,

“After observing your dedication over the three years since the beginning, we felt confident because you’ve been consistently focused on this. “European companies appreciate this kind of challenge mindset.”

Kojima

I see. How many years have you been attending overseas trade shows?

Kasahara

We’ve attended Paris for six years, New York for two years, and then Frankfurt for five years.

Kojima

Did it ever cross your mind to stop going?

Kasahara

No, I never thought that. After all, the Japanese market is shrinking rapidly, isn’t it?

So, instead of aiming for Japan’s population of 120 million, our target is the world’s 8 billion people.

Kojima

Was it confidence in your technical abilities that allowed you to take that risk and head overseas?

Kasahara

Well, we did have confidence in our technical abilities. But foreign trade shows cost money, right? It was difficult to keep investing all that time. But by sticking with it, we were able to develop a track record, continuously attending shows overseas, and even gaining recognition in Japan.

Working to Increase the Value of Embroidery

Q: What challenges do you think the embroidery industry faces today? And what sorts of initiatives are you pursuing to deal with those challenges?

Kasahara

Our company’s main focus has always been on embroidery for apparel, and working with apparel is what I enjoy most. We take on unusual designs and produce them as embroidery.

I truly enjoy this type of research, but ten years from now, I think it’s probably going to be impossible to stay in business with this format. After all, things have to change.

However, I can’t simply advocate for change. I don’t think that brings out each employee’s individual strengths. We hold a study session called “Kasamori People’s Day” that everyone joins in on. If we only think of things as an extension of current technology, you won’t be able to impress people, and we won’t be able to get the customer’s support. That’s why we decided to start with human resource development.

Kojima

That’s exactly right.

I think you could say this not only about the embroidery industry, but about any small and medium-sized enterprise. For example, say, a company in the machining sector wants to produce finished end products in-house. That would require them to make changes, starting with their culture. But many companies haven’t got that mindset. I think each individual will need to look at and think about a variety of different things, and then incorporate all that into their manufacturing processes.

Kasahara

Yes, that’s right.

Kojima

Taking a manufacturer’s perspective, we often hear that compared to the past, the unit price of embroidery itself has declined.

Embroidery was originally something whose value lay in the sense of richness it produces, but the fact that prices for embroidery are falling is a significant concern.

I want our company to engage in comprehensive, detailed discussions with our customers, listen to their insights regarding their future needs, and integrate this information into our development process

Kasahara

Unit prices are definitely falling.

While the scale of the apparel market has shrunk by half over the past thirty years, the number of products has roughly doubled. This means that the individual items are cheaper, making it harder to add embroidery to regular priced items.

We have no choice but to appeal to the premium brands that can add embroidery. I think that’s the most important point.

Kojima

Yes, it’s important to make proposals to the top apparel brands.

We are also collaborating with artists to create modern and contemporary art through embroidery. We combine artists’ creativity with Tajima’s technology to create captivating artwork, bringing joy to the viewer and enhancing the value of embroidery.

Kasahara

If Tajima assumes leadership and we all come up with ideas like “Can’t we do more of this?” and “Let’s create that kind of market,” I think the result will be new markets appearing.

Kojima

In that respect, our company now offers a service called “DG.NET” to meet the demand for personalized embroidery. One way to be competitive as embroidery prices continue their decline is to create end products, as you do, Chairman Kasahara. Others, though, may feel that’s too high a hurdle.

I think those folks will be more likely to succeed if they try personalization.

Kasahara

I saw DG.NET at a trade fair and thought it was amazing.

There is no question that the market for personalization is going to expand as times change.

There’s also made-to-order. Since we manufacture products only after receiving an order from the customer, we don’t need to maintain any product inventory. I think the market is going to trend in that direction.

Continuing to Change While Leveraging Japan’s Strengths

Q: Please tell us about your commitment to “Made in Japan.” What special kind of value can you provide due to the products being made in Japan?

Kasahara

To be honest, technologies in foreign countries have improved considerably.

So, we can’t simply rely on the notion of “This is good because it’s made in Japan.” Rather than leaving it at that, I think we need the commitment to go one step further.

The extra thoughtfulness that shows people the extent of your care and dedication. I think that is the spirit of “Made in Japan.”

Kojima

Just as you say, Chairman Kasahara, I think the strength of the Made-in-Japan label has waned considerably.

Being headquartered and having developed in Japan, we in the Tajima Group are working to boost the impact of “Made in Japan.” The average Japanese person is hardworking, and many are highly capable. That’s how I came to be good at making things. But now, with needs diversifying and the accelerating pace of change, I think the typical Japanese characteristic of tidy elegance in manufacturing. might be limiting our progress.

Going forward, we’ll continue to lean into our traditional diligence as we also continue to change, with the customers’ needs reflected in our products. I think it’s extremely important to create a manufacturing enterprise that can keep changing.

Kasahara

From the standpoint of human resource development, it is important to create opportunities to see different things.

We get to see other factories, and we let people from other companies see our factories. Without recognizing current conditions as they are, we’ll end up convinced that what we’re doing now is the right thing to do. When we hold our “Kasamori People’s Day” the employees who feel they have improved the most are those who create the study group programs. Being on the teaching end gives them a different perspective than before.

I think those who experience that growth develop a sense of crisis and think, “Is it really okay to continue this way?”

Kojima

That’s right.

Our company also believes that each individual employee’s positive outlook and self-directed efforts are extremely important. We want them to achieve a broader perspective, considering things from the company’s position— what we need to do as a company for our customers —and then go on to think, “Well, here’s what my department should do.” However, I don’t think people who work passively are even close to having that perspective.

What’s important now for the Tajima Group is that each individual have a purpose in life, to think about who and what they are living for, and why they are working for the Tajima Group. I believe that people who consciously choose to work for the Tajima Group in order to achieve a particular aim are sure to become self-directed, positive-thinking individuals. And I believe such people will create an organization that is capable of change.

Q: Finally, Chairman Kasahara, could you tell us what you expect from the Tajima Group?

Kasahara

As I mentioned earlier, I hope Tajima can innovate and create something that sparks the thought, “I wish I could do such-and-such with embroidery.”

Instead of watching a rapid contraction of the embroidery industry, we’ll see the market continue to expand. To get there, I would like Tajima to think about things that have never been possible before. I absolutely believe it can result in something interesting, such as embroidering on soft materials or sewing without any bobbin thread.

I really would appreciate you thinking about this.

Kojima

Thank you very much. We will do our best to meet your expectations.

The Tajima Group’s history is one of mechanization to achieve what was previously impossible, and growing as our customers came to rely on us. I want to do more and more of the things we haven’t been able to do before.

Kasamori Corporation | Enhancing Daily Life Through Embroidery. The Story of Developing a New Brand by Kasamori Corporation.

Kasamori Corporation launched its accessory brand 000 (Triple O) in 2010. What’s special about these…