Taking your first step into the world of embroidery starts with understanding embroidery threads, which play a crucial role in determining the beauty and durability of the finished design!

In this article, we will introduce the basics of embroidery threads used with embroidery machines, covering their types, characteristics, and key points in detail. Whether you’re a beginner or looking to deepen your knowledge, this guide is designed to be easy to understand—so be sure to check it out!

INDEX

Upper threads

Embroidery Thread Materials and Selection

There are various types of threads, but in embroidery, rayon threads, polyester threads, and 120d/2 threads are commonly used. For delicate details, finer threads such as 75d/2 are preferred.

The material and thickness of the embroidery thread significantly affect the final outcome, so selecting the right thread for the intended application is essential!

Material

There are two main types of upper threads used for embroidery: rayon threads and polyester threads.

・Rayon threads are commonly used due to their vibrant colors and glossy finish. They are also heat-resistant, making them ideal for applications like heat-cutting patches.

・Polyester threads, on the other hand, are recommended for embroidery on sports uniforms and other durable items. They are strong, resistant to thread breakage during embroidery, and easy to handle, making them a good choice for beginners.

| Material | Advantages | Disadvantages |

|---|---|---|

| Rayon Thread |

– Glossy finish: Adds a beautiful shine to embroidery. |

– Prone to breakage: Requires careful handling. |

| Polyester Thread |

– High strength: Provides excellent durability for long-term use. |

– Less glossy than rayon: However, some newer polyester threads closely resemble rayon in shine. |

Thread Thickness

Thread thickness is commonly expressed in denier (d), an international unit that indicates the fineness of the thread.

The larger the number, the thicker the thread, while the smaller the number, the finer the thread.

・Fine threads are suitable for delicate embroidery.

・Thicker threads create a bold and prominent finish.

Choose the appropriate thread thickness based on your design and fabric.

- 75d ― Fine embroidery thread

- 120d ―Standard embroidery thread

- 200d ―Thick embroidery thread

Thread Twisting and Twist Direction

■Thread Twisting

Embroidery threads are made by twisting multiple strands together into a single thread.

In notations such as 120d/2 or 75d/2, the final “2” indicates that two threads are twisted together. For example, a 120d/2 thread consists of two standard 120-denier embroidery threads twisted into one.

Twisting improves the thread’s strength and helps prevent breakage during embroidery.

■Twist Direction

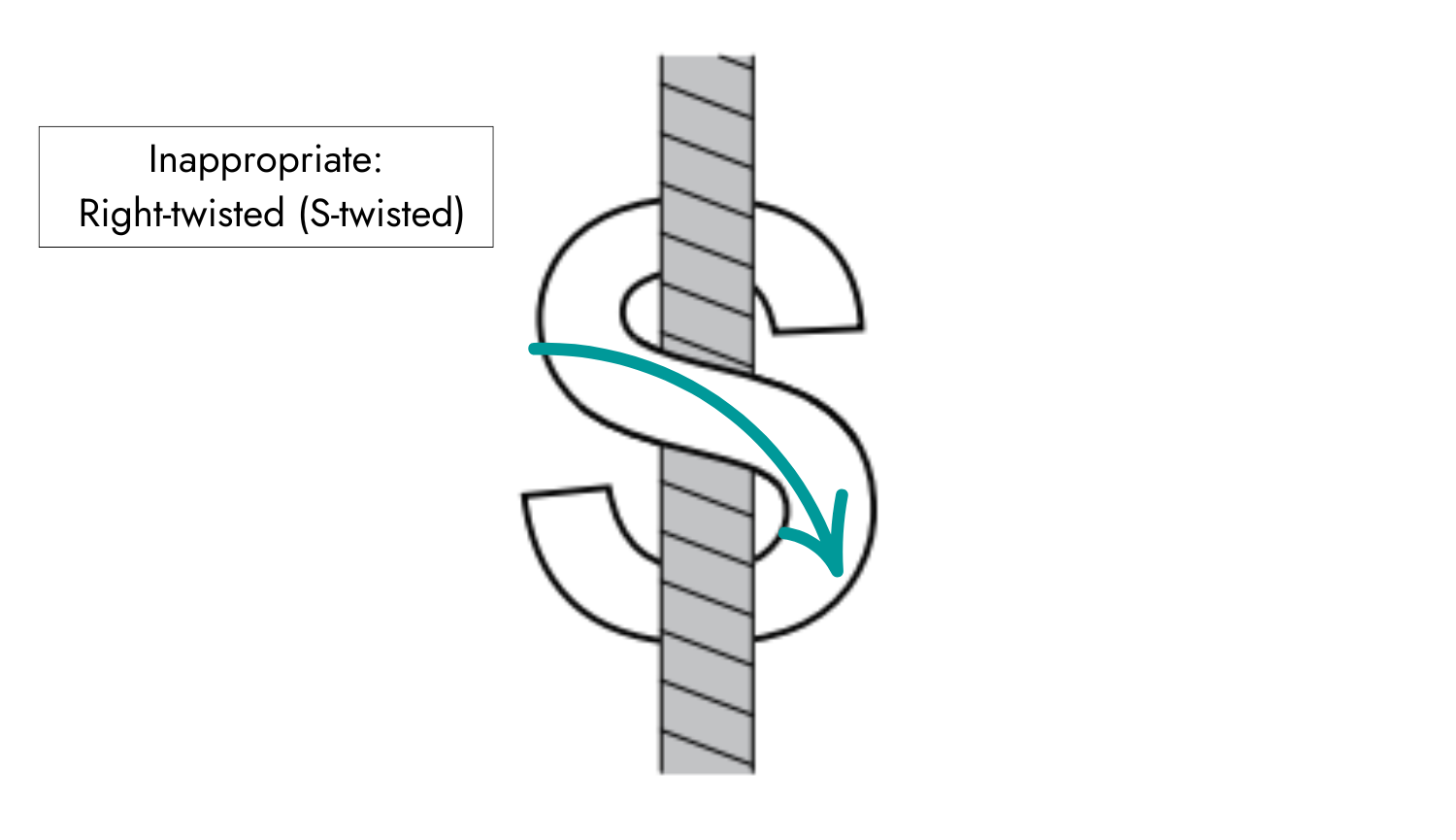

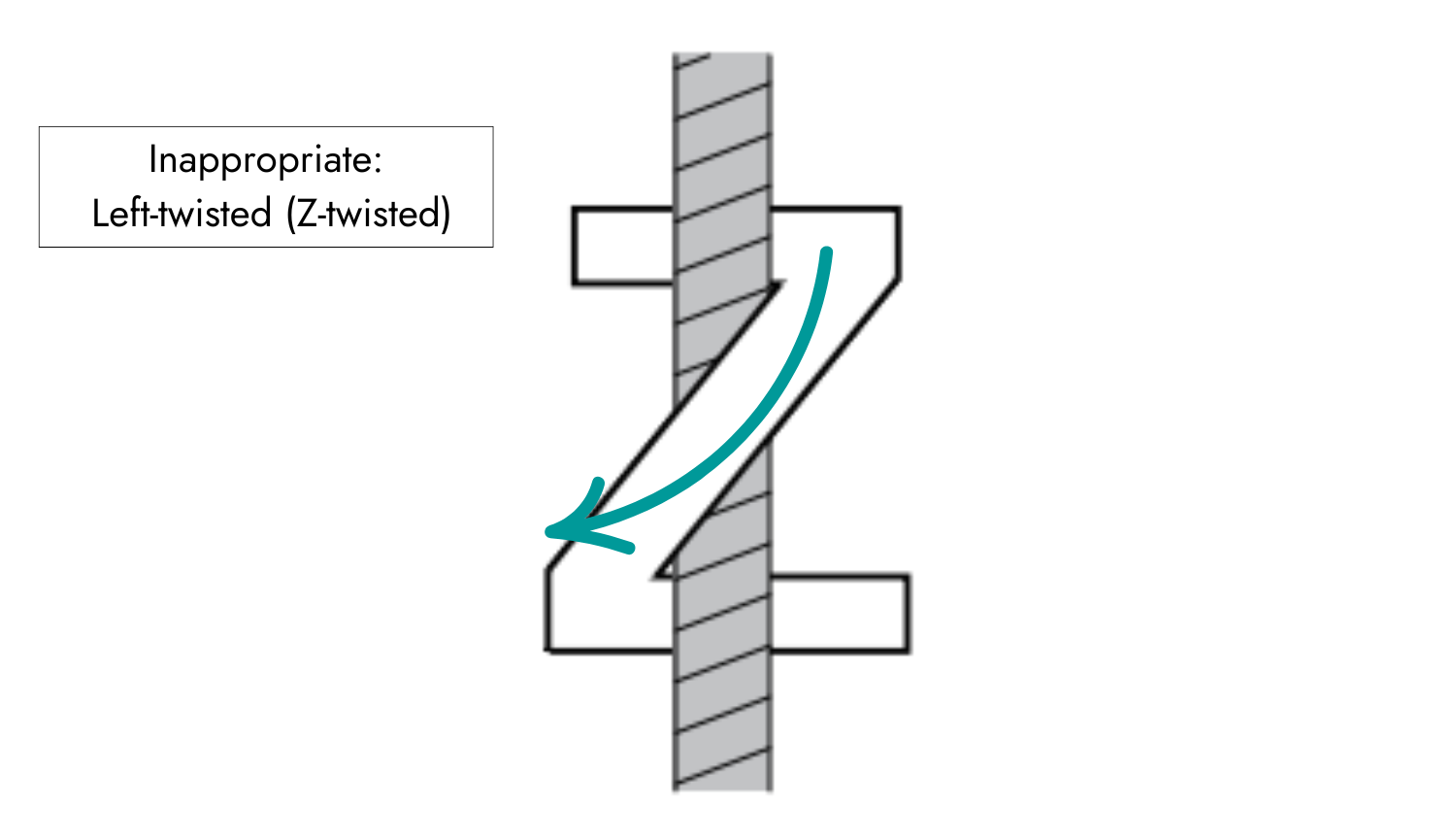

The common twist directions for embroidery threads are right-twisted (S-twisted) and left-twisted (Z-twisted).

When using an industrial embroidery machine, always use Z-twisted (left-twisted) threads. Since the rotary hook that holds the bobbin rotates counterclockwise, Z-twisted threads remain tightly twisted, reducing the risk of breakage.

On the other hand, using S-twisted threads can cause the twist to loosen during embroidery, leading to thread separation and frequent breakage.

*How to Identify the Twist Direction: Hold the thread horizontally with both hands and rotate your left hand backward (away from you).

・If the twist loosens, it is Z-twisted (left-twisted).

・If the twist tightens, it is S-twisted (right-twisted).

Under Threads

Selection of Under Threads

It is common to use cotton or polyester spun threads as under threads. To ensure a soft finish on the back of the fabric, it is recommended to use the finest possible thread, preferably equivalent to count number 120.

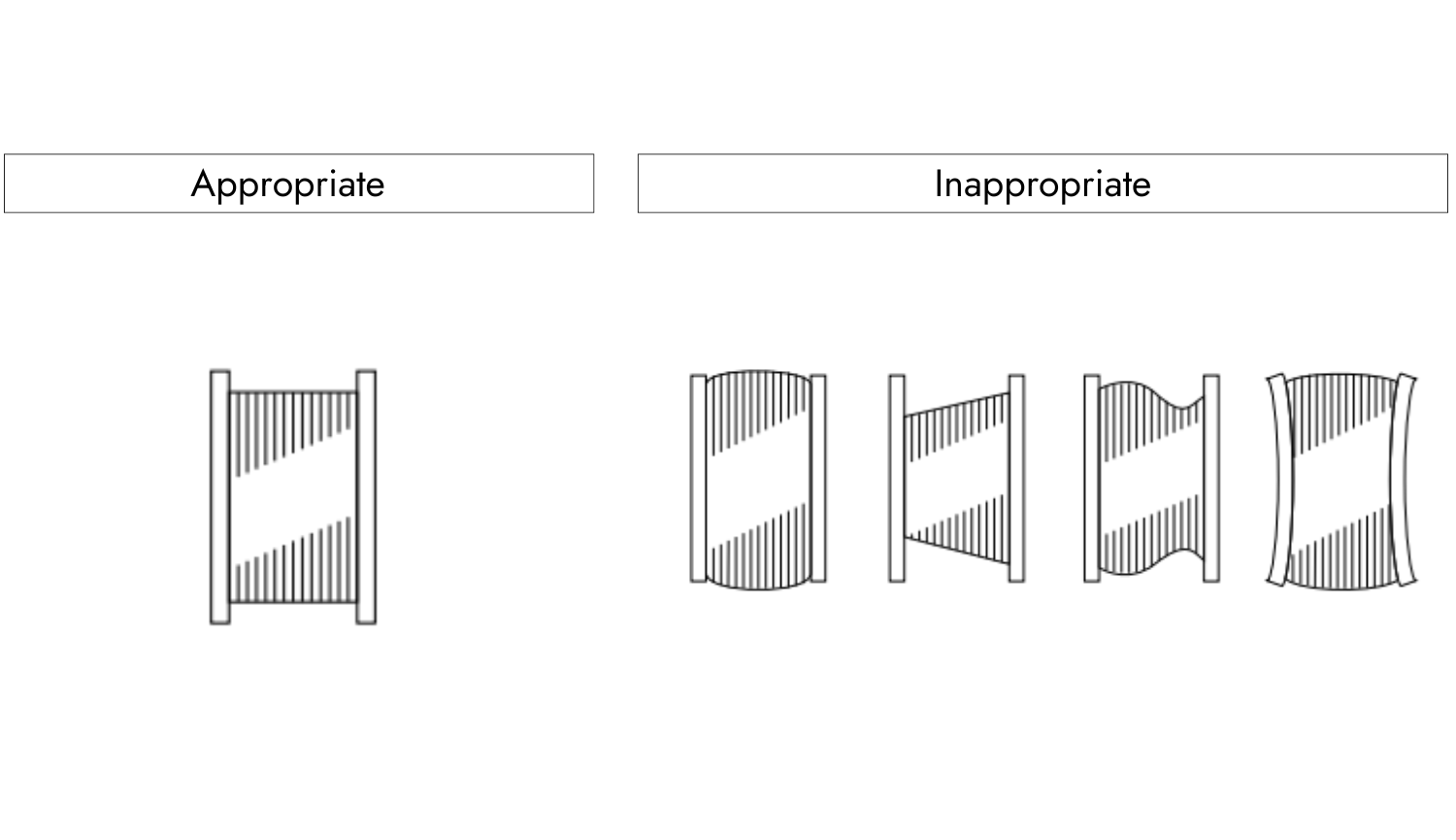

Winding Amount of Under Threads

Use a bobbin that is evenly wound with an appropriate amount of under thread.

Overwinding or uneven winding may result in thread breakage, biting, or poor stitching quality.

There are various types of embroidery threads beyond those introduced, including gold and silver threads. By understanding the different types and characteristics of threads and selecting the most suitable one for your purpose, you can achieve more beautiful and durable embroidery.

Choose the right thread for your embroidery project and aim for the perfect finish!