In recent years, the growing demand for personalization and the expansion of fandom culture have led to more people starting embroidery businesses. That being said, many people may wonder, “What types of embroidery machines are available?” or “How do I choose the right one?”

A Must-Read for Anyone Looking to Start an Embroidery Business!

We’ll guide you through the basics of embroidery and key points for choosing an embroidery machine in detail. Embroidery machines come in a wide variety, ranging from large-scale industrial machines used in factories to compact home-use models for easy embroidery at home. In this article, we’ll explore different types of embroidery machines and the important factors to consider when purchasing one!

Many people may be wondering, “What exactly is an embroidery machine?”

Let’s go over the basics of embroidery while finding the perfect embroidery machine for the business you want to start!

INDEX

Types of Stitching

Embroidery can be broadly categorized into two main stitching methods: lockstitch embroidery and chainstitch embroidery. Among these, lockstitch embroidery is the most commonly used technique in embroidery machines. From here, we’ll take a closer look at the key factors to consider when choosing a lockstitch embroidery machine!

Lockstitch Embroidery

Lockstitch embroidery is a method that forms stitches by intertwining two threads: an upper thread and an under thread. The most commonly seen embroidery is “flat embroidery”, which falls under this category of lockstitch embroidery.

Additionally, embellishment techniques such as sequin and bead embroidery are also considered lockstitch embroidery. These techniques require specialized attachments that can be installed on embroidery machines to complete the process.

Chainstitch Embroidery

Chainstitch embroidery is a method that uses a single thread looped together to create stitches, giving it a distinctive texture and three-dimensional appearance. One well-known example of this technique is “sagara embroidery” (chenille embroidery).

This type of embroidery is commonly used for jackets, patches, and children’s clothing, adding a unique and decorative touch to the fabric.

Point 1 | Types of Embroidery Machines

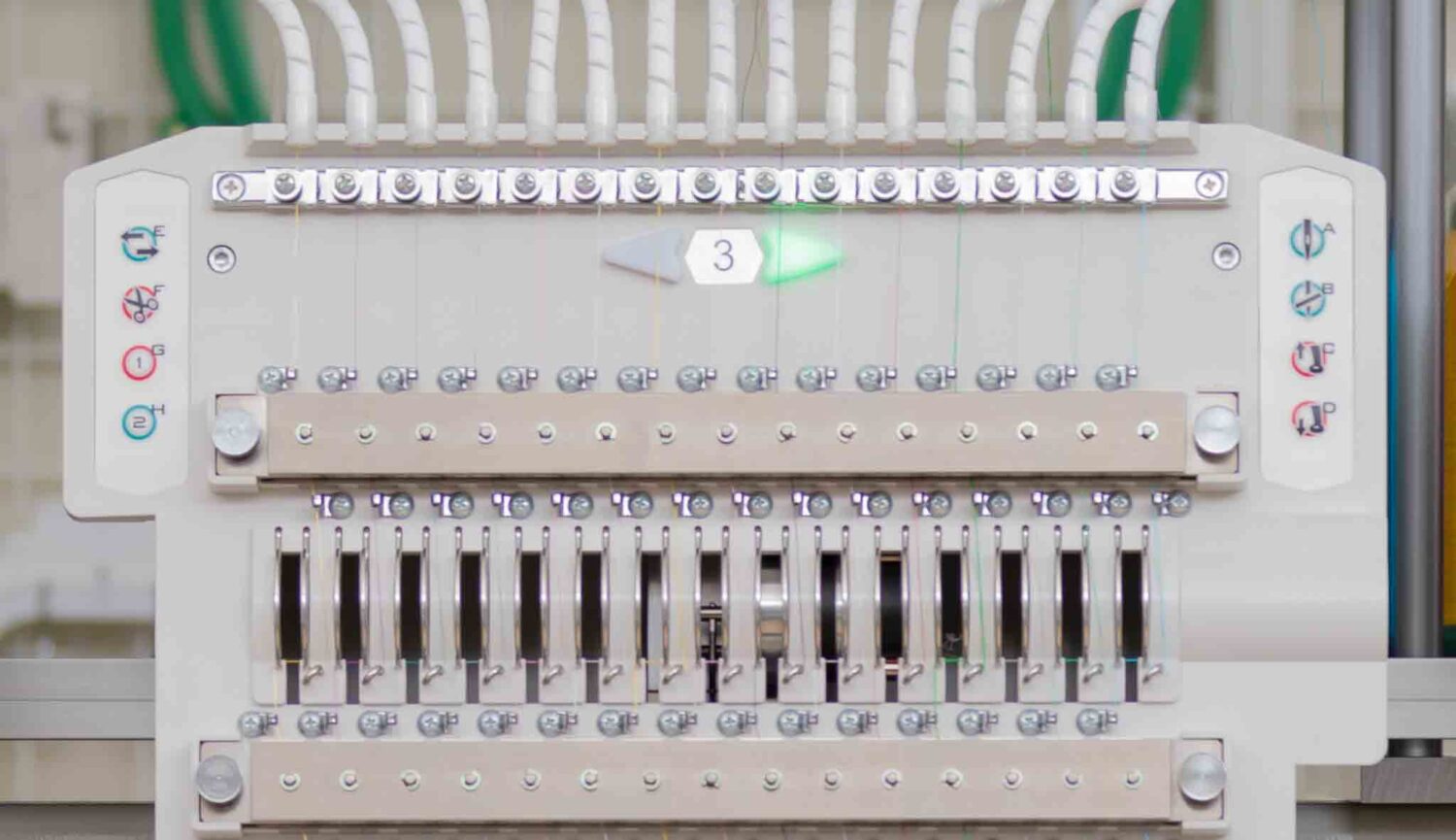

Needles

Unlike household sewing machines that use a single needle, embroidery machines are equipped with multiple needles. Each needle is assigned a different thread color, eliminating the need to manually change threads and allowing for smooth, multicolor embroidery.

The number of needles varies depending on the manufacturer and model, but 9 to 15 needles is the most common range. Machines with more needles require fewer thread changes, enabling efficient embroidery of a wide variety of designs to meet customer orders.

Head Configuration

An embroidery head refers to the set of mechanisms needed to stitch a single embroidery design, with each head equipped with multiple needles.

・Single-head embroidery machines have one head and are ideal for small-scale production and custom orders.

・Multi-head embroidery machines have multiple heads, allowing them to embroider the same design simultaneously, greatly improving production efficiency.

Single-head Type

Single-head embroidery machine can embroider one item per operation, making it ideal for name embroidery, personalized embroidery, and custom orders that require individual processing.

Multi-head Type (2–8 Heads)

Small-scale multi-head embroidery machines are well-suited for logo embroidery on uniforms, caps, and small to medium production runs, offering both efficiency and flexibility.

Multi-head Type(9+ Heads)

In large-scale factories, embroidery machines with 50 or more heads are used. These machines are ideal for mass production, such as apparel OEM manufacturing, where embroidery is applied to a high volume of products.

Embroidery Field

The embroidery field refers to the maximum area that can be embroidered in a single operation. For example, if the embroidery field is 200mm × 300mm, designs and patterns must fit within 200mm in width and 300mm in height.

When selecting an embroidery machine, consider the items and designs you plan to embroider, such as uniforms, caps, or socks, and choose a machine with a suitable embroidery field. For large-scale embroidery on items like curtains or bedding, a flatbed embroidery machine capable of handling roll fabric may be required.

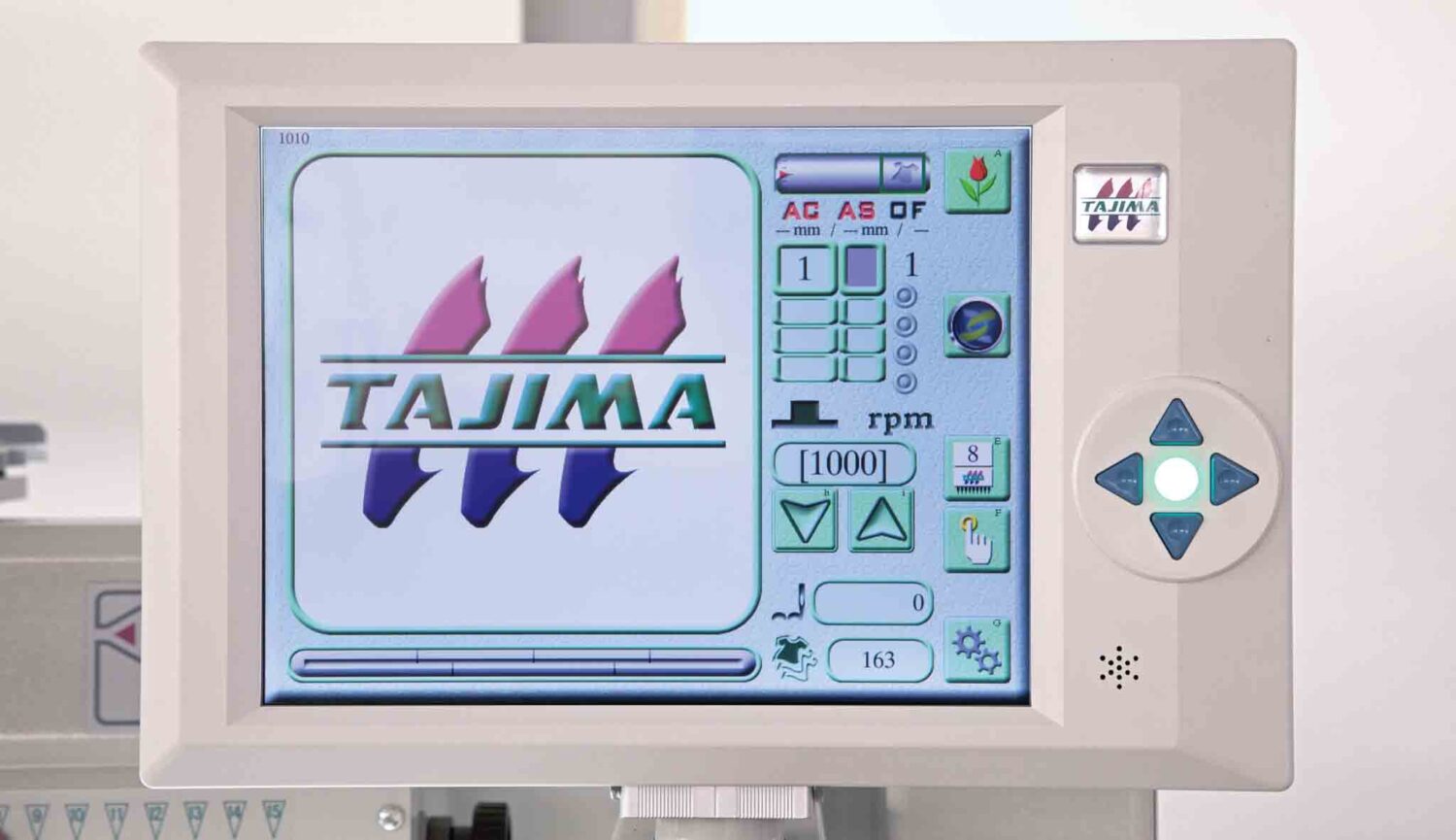

Embroidery Machine Speed

The speed of an embroidery machine is a key factor in increasing production output.

Embroidery speed is typically measured by the number of needle movements (rotations) per minute. The unit rpm (revolutions per minute) is used to indicate this, meaning that 1,200 rpm represents 1,200 needle movements per minute.

To maximize production efficiency, it is essential to set the appropriate speed and ensure stable.

Convenient Support Features

Manufacturers offer embroidery machines equipped with support features that make them easy to use, even for beginners. If you are concerned about operating skills or securing trained operators, it is important to check not only the basic functions but also the available support features.

Since standard features vary by manufacturer, selecting an embroidery machine with the right support functions based on operator skill level and business environment is essential.

Tajima Group offers a wide range of user-friendly features and options designed to enhance the operator’s experience!

Automatic Upper Thread Tension Adjustment

Automatic Presser Foot Adjustment

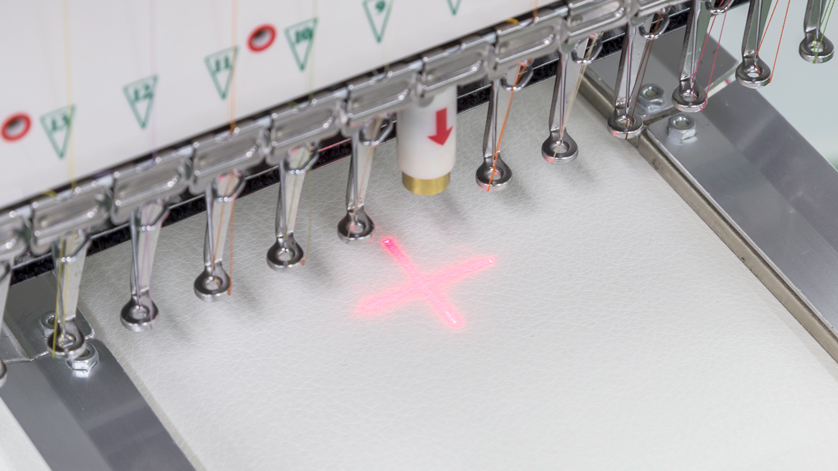

Laser Crosshair Marker

Automatic Bobbin Changer

Individual Head Operation Switches

User-Friendly Display

Embroidery Frame

When performing embroidery, an embroidery frame is essential to secure the fabric in place. Choosing the right frame size according to the fabric type, product, and embroidery design size ensures proper stabilization and a high-quality finish. Embroidery frames come in various types, such as magnetic frames and screw-fastened frames, with usability being an important factor. When selecting an embroidery machine, it is advisable to check whether it supports a wide variety of embroidery frames and whether its design enhances ease of use and efficiency.

Explore manufacturer embroidery frames for various applications here.

Point 2 | Create Original Designs with Embroidery Digitizing Software

To create original embroidery, you need embroidery digitizing software in addition to an embroidery machine. While some household embroidery machines come with pre-installed embroidery designs, creating custom embroidery requires one of the following methods:

1.Outsource the embroidery digitizing process.

2.Use embroidery digitizing software to create the data yourself.

For those who want full creative control, purchasing embroidery digitizing software is highly recommended!

By mastering digitizing, you can greatly expand the possibilities of embroidery—consider giving it a try!

Tajima Group offers a variety of embroidery digitizing software to suit different needs!

Explore our embroidery digitizing software here !

“DG” – Transform creativity into reality with embroidery digitizing software for all skill levels.

“Autograph” – Specialized embroidery digitizing software for name embroidery.

“WriterPLUS” – Standard embroidery digitizing software included with SAI.

Point 3 | Support System at the Time of Purchase

Choosing an embroidery machine from a reliable manufacturer or brand is crucial.

Be sure to consider the following key points when making your selection!

- Machine Inspection Availability – Can you see and evaluate the actual embroidery machine before purchasing?

- Information Accessibility – Is there sufficient information available regarding quotes and purchase details?

- Installation Support – Does the manufacturer provide adequate assistance for delivery and initial setup?

- After-Sales Support – In case of machine failure, can repairs be handled quickly and efficiently?

- Sales & Support System – Are there authorized dealers or local distributors, and is online support readily available?

Point 4 | Steps to Purchase an Embroidery Machine

-

1

Contact a local distributor

Start by reaching out to a distributor in your area for inquiries. -

2

See and experience the machine in person

Visit a trade show or showroom to see and test the embroidery machine firsthand. -

3

Request a quote

Obtain a price estimate through the distributor. -

4

Compare, evaluate & finalize your purchase

Once you decide to proceed, coordinate with the distributor to arrange delivery, payment, and installation details.

In this article, we covered “How to Choose the Right Embroidery Machine Without Regret.”

Tajima Group offers a wide range of embroidery machines, from the compact “SAI”, ideal for embroidery business startups, to the AI-powered “TMEZ Series” and the “TCMX” chainstitch handle embroidery machine, capable of sagara embroidery.

With over 60 distributors worldwide, Tajima delivers embroidery machines to 160 countries and regions.

If you’re considering a purchase, feel free to contact your local Tajima distributor!