As one of the world’s largest custom embroidery and patch manufacturers, World Emblem has long focused on extending the reach of craftsmanship while staying true to its essence. At the center of that effort is PulseID, Tajima Group’s cloud-based platform that streamlines the embroidery supply chain by connecting information from order intake through production. By creating a system that connects human creativity with technology, World Emblem now delivers consistent embroidery quality across all of its global locations. We spoke with CEO Randy Carr about how the company achieves both operator-independent precision and speed—and what drives its ongoing evolution.

The System that Amplifies Craftsmanship — How PulseID Drives World Emblem’s Evolution

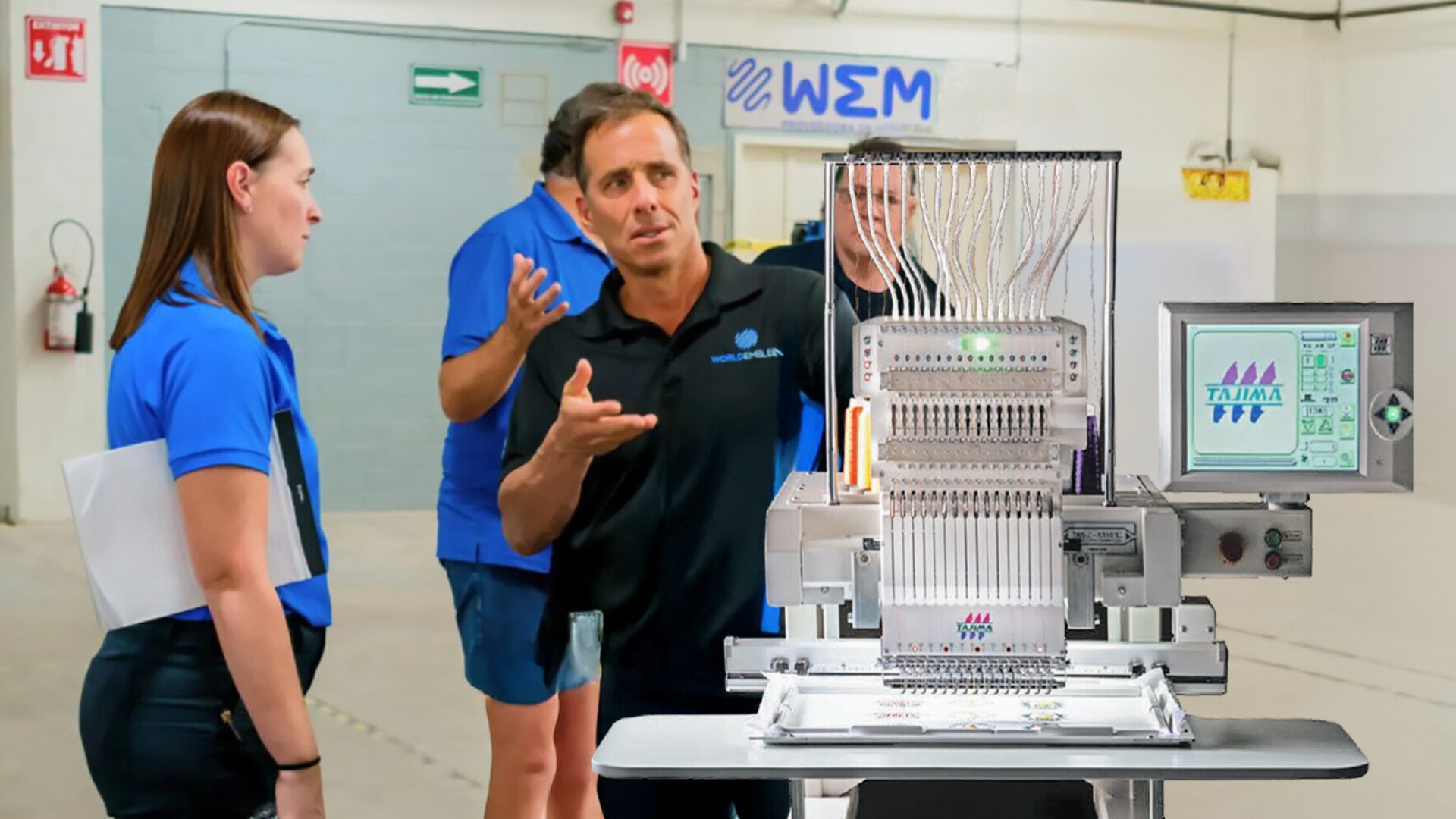

World Emblem CEO Randy Carr

World Emblem

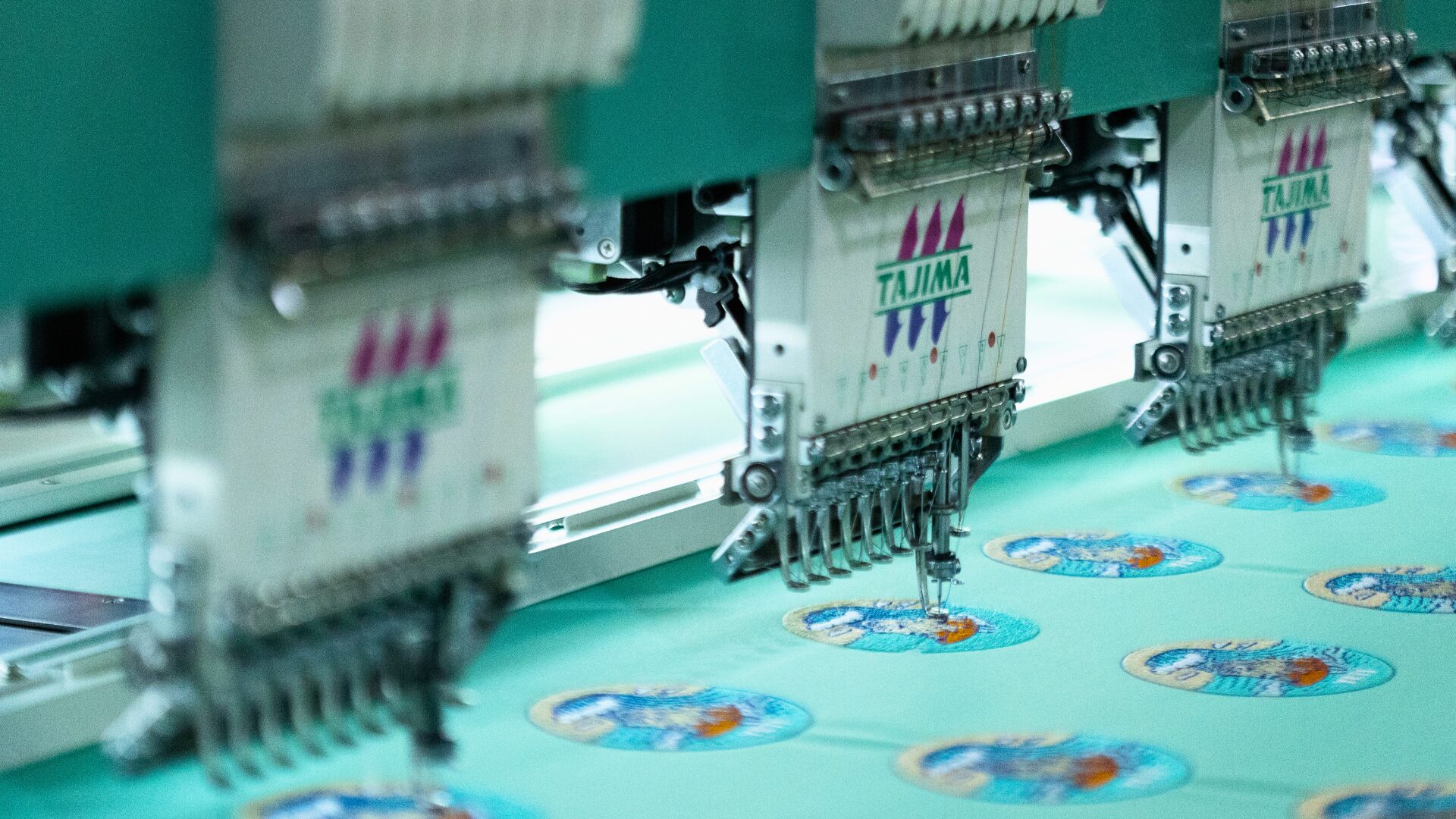

Headquartered in the U.S., World Emblem is a globally operating custom embroidery and patch manufacturer. The company runs approximately 4,000 embroidery heads across multiple production sites in the U.S. and overseas, supplying high-quality embroidery for apparel, sportswear, and promotional products. To balance efficiency and quality, World Emblem has built a digitally connected workflow and adopted automation technologies—initiatives that continue to support its growth.

How has World Emblem evolved over the years?

We started as a small embroidery business and have steadily grown into one of North America’s leading custom embroidery and emblem manufacturers. Today, we operate multiple facilities across the U.S., have one in the United Kingdom, and are preparing to expand into the Dominican Republic. Across all of our sites, we run about 4,000 embroidery heads, supplying products to apparel brands, sportswear manufacturers, and promotional product companies worldwide. Beyond production, we brought digital design and logistics in-house early, allowing us to manage the entire process—order to delivery—seamlessly. Our growth has been driven by precision, stability, and above all, long-term trust with our customers.

What led you to choose Tajima’s embroidery machines?

What stood out most when we evaluated Tajima was the precision and durability of the machines. To achieve consistent stitch quality across all of our sites, standardizing on Tajima equipment was clearly the right choice. With the strong support of Hirsch Solutions, Tajima’s U.S. distributor, the transition went smoothly and the machines have remained very stable in operation. Reliable engineering and a strong partnership—those are the reasons we chose Tajima then, and why we continue to rely on them today. Whenever we open a new facility, Tajima machines are essential to ensuring consistent quality worldwide.

What changes have you seen since introducing the TMEZ series?

We recently introduced the TMEZ series equipped with Tajima’s original AI technology, i-TM, which automatically adjusts the upper thread tension. From the very beginning, we saw clear improvements in setup time and stitching stability. Because i-TM automatically adjusts the tension according to stitch type and material, we no longer depend on operator experience—making it much easier to train new team members. This has been especially effective with high-performance fabrics like stretchable sportswear, where consistency is essential. We are continuing to test various materials and plan to expand the TMEZ series to other facilities based on our results.

What impact has PulseID had since its introduction?

PulseID plays a central role in our digital production management. We automatically generate around 10,000 embroidery files each day and manage over two million design assets in the cloud. By linking order information directly to the embroidery process, we have eliminated manual setup and ensured precision and consistency across all of our locations. Personalized elements—such as color changes or name variations—are also handled automatically, allowing our operators to focus on higher-value work like quality checks and production planning instead of repetitive tasks. Because every facility follows the same data and procedures, we can maintain stable, location-independent workflows across the entire company.

Automation does not take away craftsmanship—it helps make it repeatable for everyone. With Tajima’s technology, we have been able to deliver the same level of quality and precision around the world. PulseID is a system that preserves craftsmanship while scaling it across our entire operation.

What do you look forward to in your partnership with Tajima?

We have high expectations for how Tajima will continue integrating data, AI, and automation into its products and services. These technologies are essential to the next stage of embroidery, and Tajima is clearly leading that direction. By connecting our global production sites more closely with Tajima’s technology, we believe we can create a seamless framework that unifies design, production, and quality management. Tajima is a partner we trust—both technologically and strategically—and we look forward to continuing our shared growth in the years ahead.