PulselQ – the innovative cloud service that accelerates embroidery production efficiency

With embroidery machines always connected to the network, various tasks in embroidery production, from design management to progress tracking, are centralized. Smartphone – based embroidery operation can significantly enhance both efficiency and quality.

PulselQ provides a new embroidery experience while reducing production costs.

PulselQ Simpler, Smarter Embroidery.

Flexibility Powered by the Cloud

No need for USB transfers or manual copying. By centralizing all data in the cloud, teams of any size can access and share information from inside or outside of the company. This reduces daily preparation and data management tasks, enabling flexible and speedy production without the limits of distance or environment.

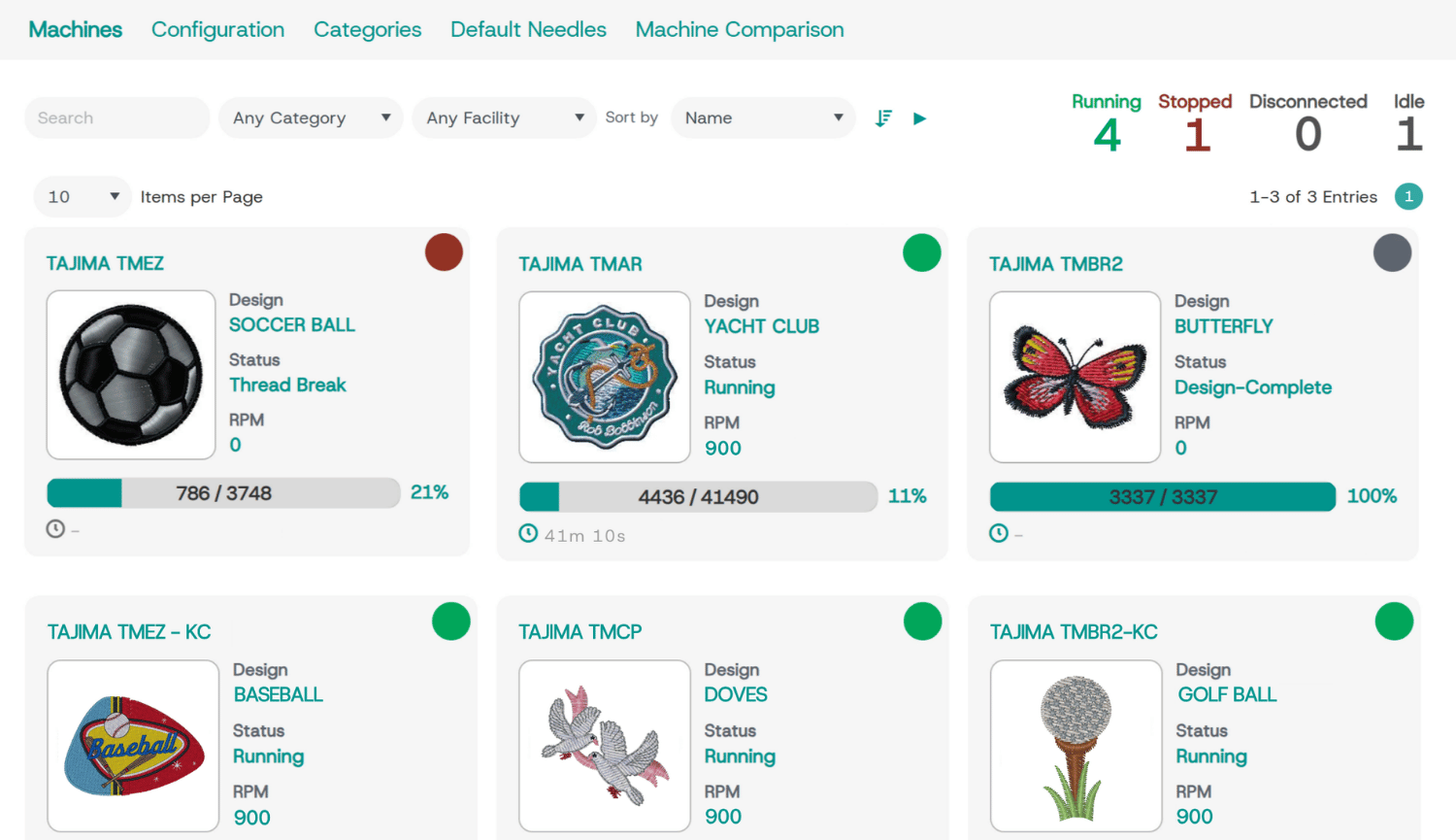

Smart Production Management through Visualization

Visualize the operation of multiple machinesand processes to gain a clear overview of factory performance. Detect workload imbalances or stoppages early, and flexibly optimize layouts and workflows. This enables swift operations and a stable, adaptive management system that responds effectively to change.

Instant Alertsfor Reliable Operation

Push notifications (*1) instantly capture embroidery completion or machine stoppages. You can respond immediately when the machine stops, preventing unnecessary downtime. Notifications let even small teams work on other tasks while keeping machines running reliably.

Recommended Features of PulselQ

-

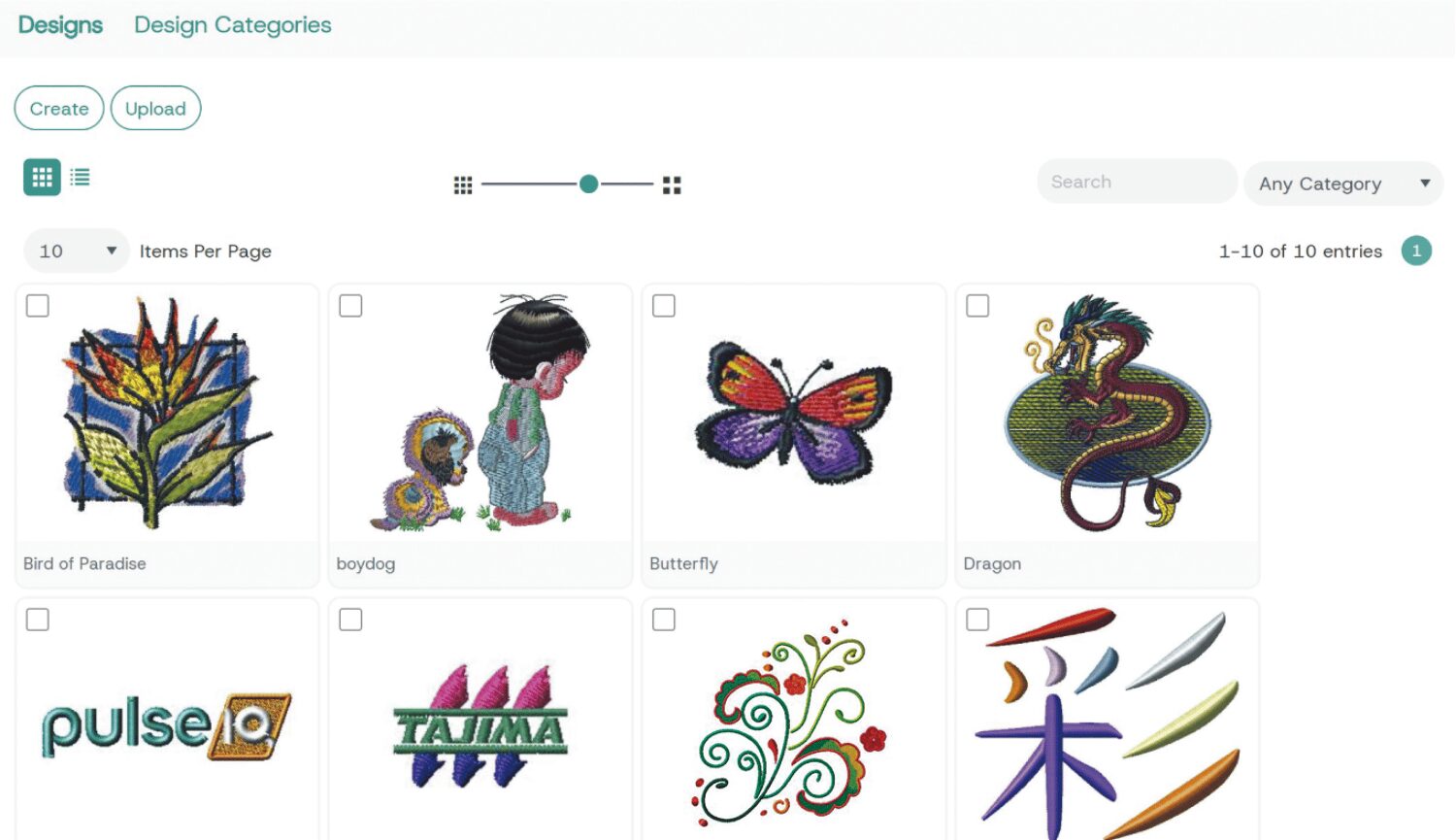

Embroidery Design Management & Editing

Equipped with a dedicated embroidery data management database. Large volumes of designs can be efficiently managed through search, tag classification, and preview functions.

In addition, thread colors can be edited directly in the cloud without using specialized software.

-

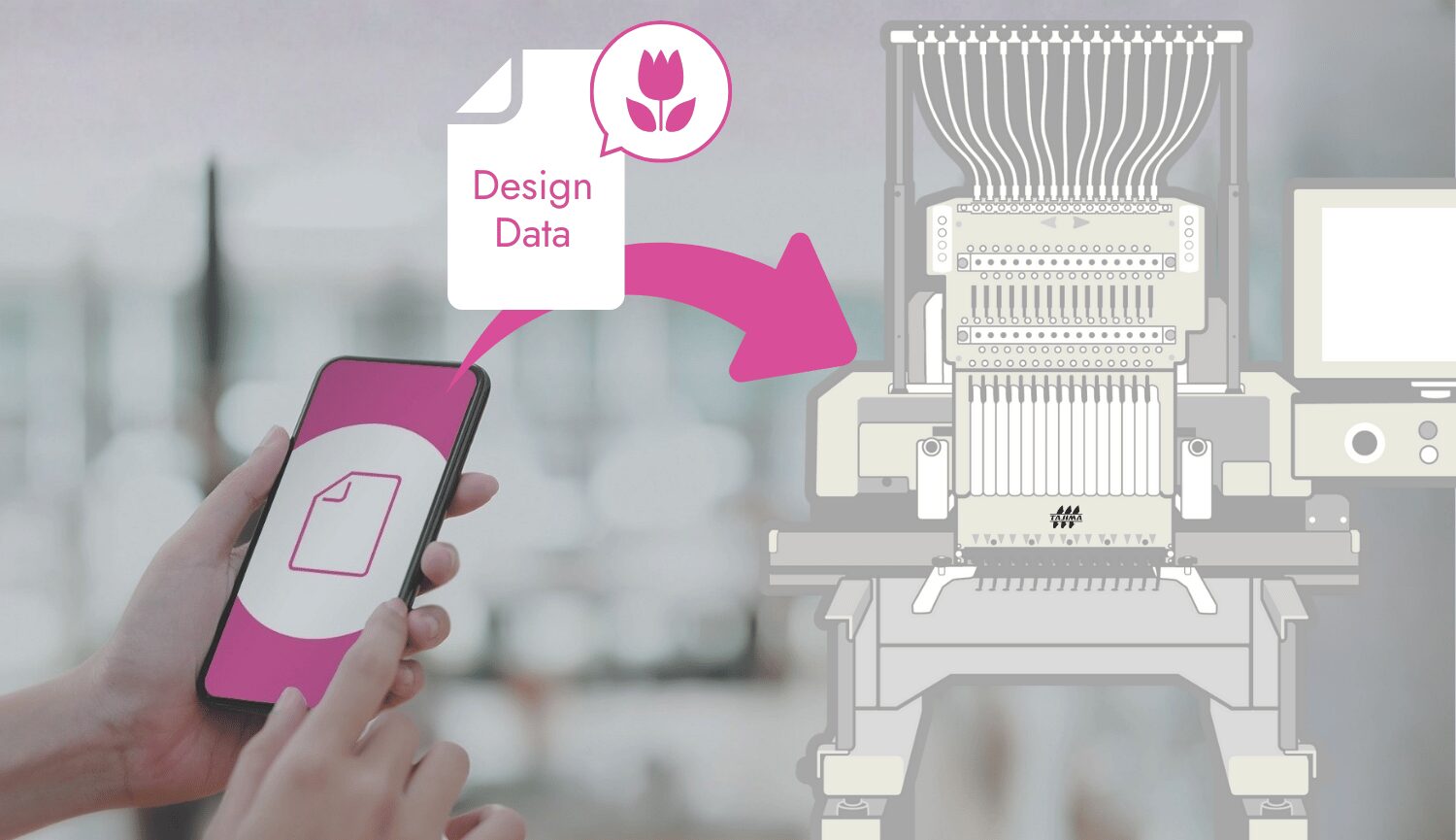

Send Designs from Your Smartphone

Embroidery data stored in the cloud can be sent directly from the dedicated mobile app (*2). USB-based data management is no longer required, and design previews as well as data retrieval can be smoothly handled via smartphone.

-

Smarter Progress Tracking at a Glance

Operating status is visualized in real time, allowing production operations and progress to be managed remotely. Design order changes and adjustments can be handled smoothly. In addition, by using the dashboard (*1), managing multiple embroidery machines becomes simple.

-

Push Notifications for Completion/Stop (Paid Option)

By linking with the mobile app (*2), embroidery status such as completion or thread breakage is instantly notified via push notifications (*1). This enables quick status awareness even from a remote location.

*1 Some features (such as push notifications and dashboard) require an additional paid option.

*2 To use PulselQ functions from a mobile device, a dedicated paid app is required.

Boosting Production Efficiency with AI Embroidery Machines

Tajima leverages its proprietary AI and digital technologies to achieve stable production of high-quality embroidery. By proposing solutions tailored to each customer’s business—from both embroidery machines and software—we support efficient and productive embroidery operations.

-

Commercial embroidery machine|Single-head Cylinder Type

TMEZ-SC

Single-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Commercial embroidery machine|Multi-head Cylinder Type

TMEZ-KC

Multi-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Commercial embroidery machine|Multi-head Flat Type

TMCR-VF+i-TM

Multi-head Flat Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-