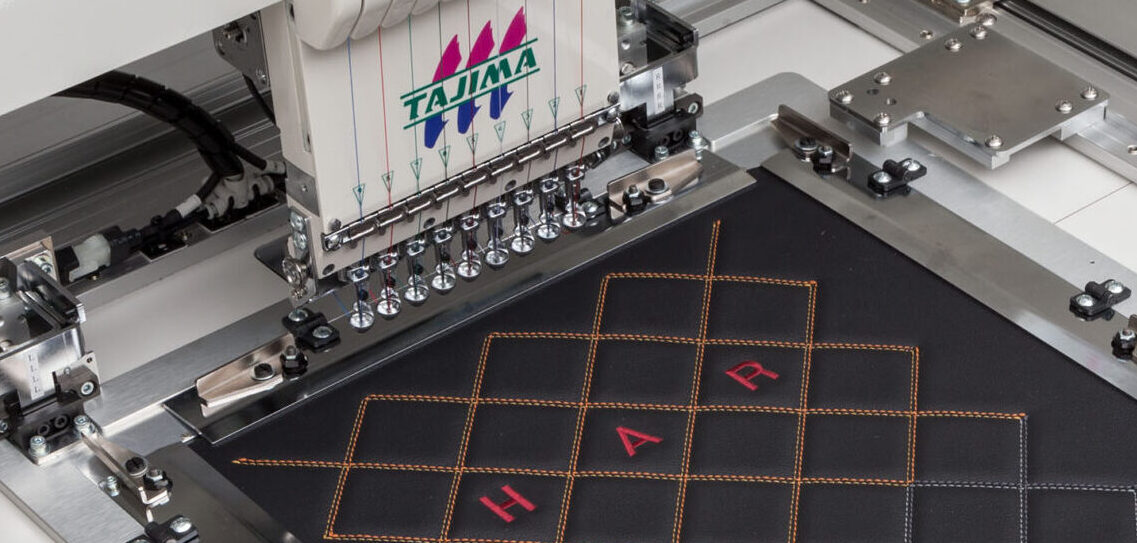

“HAR”—Sew and Embroider on One Machine

High-quality multi-color stitching and embroidery on one machine; one head handles up to 9 colors. The machine can be used for seats and interiors of automobiles, cabin cruisers, and private jets as well as for interior design, fashion accessories, and leathercraft.

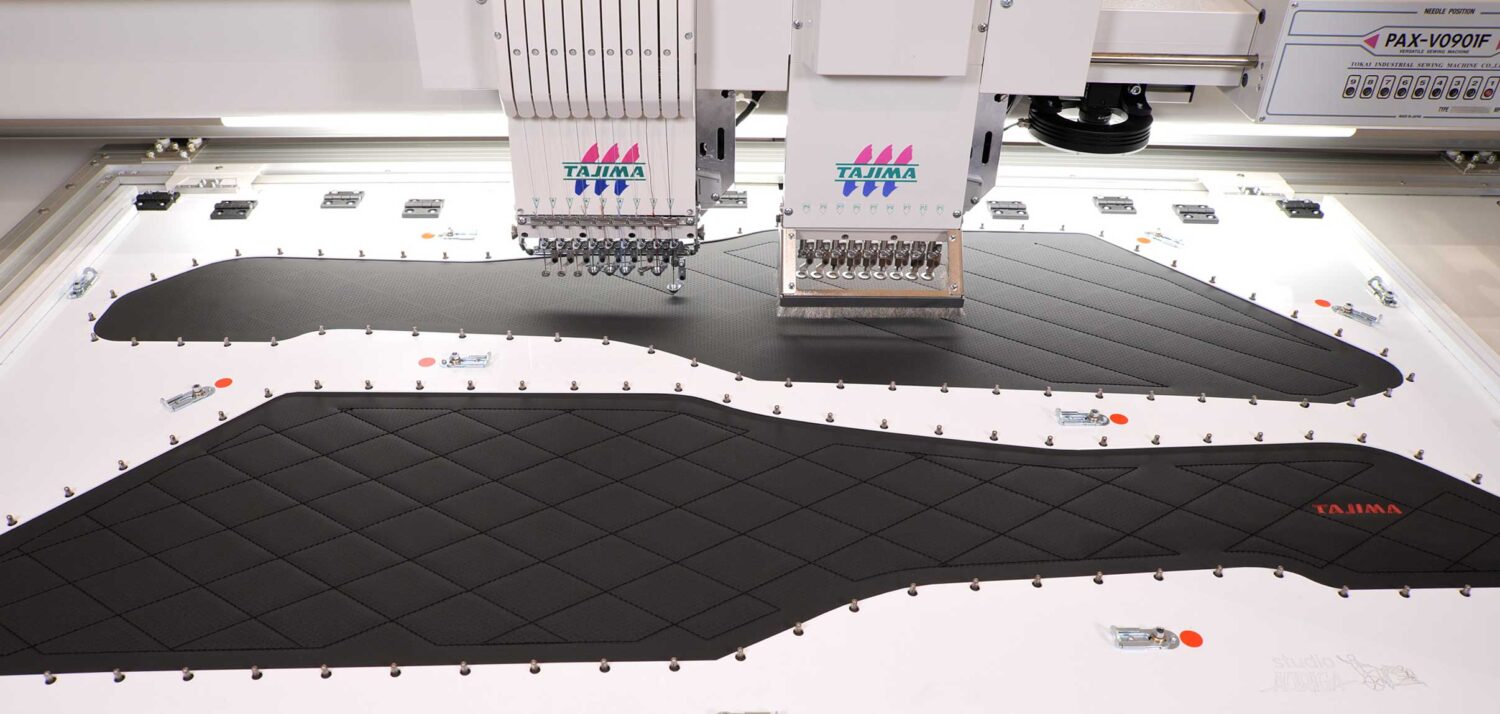

Mass production of multi-colored, vibrant designs with multiple heads

The “9 colors x 8 heads” system enables the simultaneous production of up to 8 products in a variety of styles. The sewing field is 1,000 mm (40 inches) (D) x 1,200 mm (48 inches) (W), making it possible to handle large products such as car seats and furniture, as well as a wide range of designs.

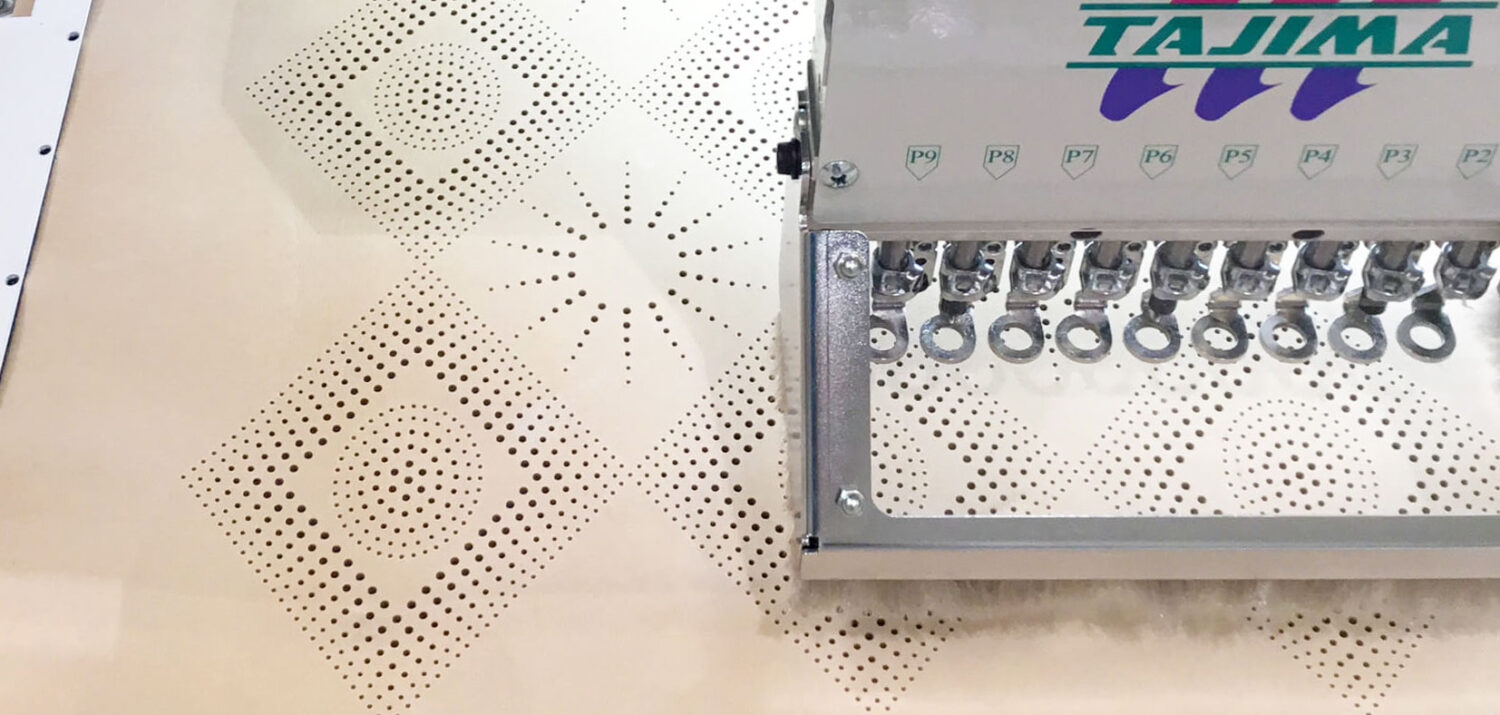

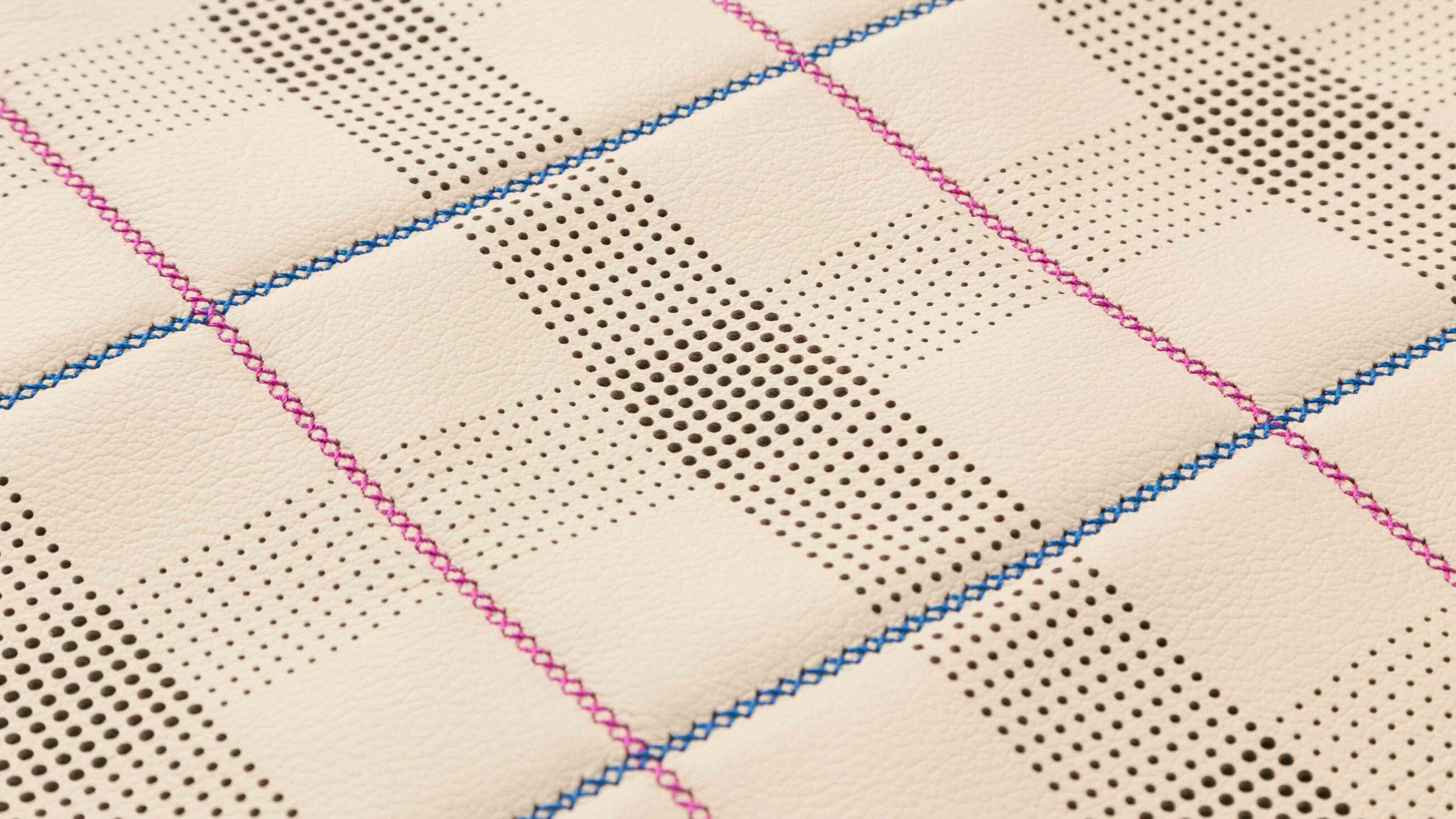

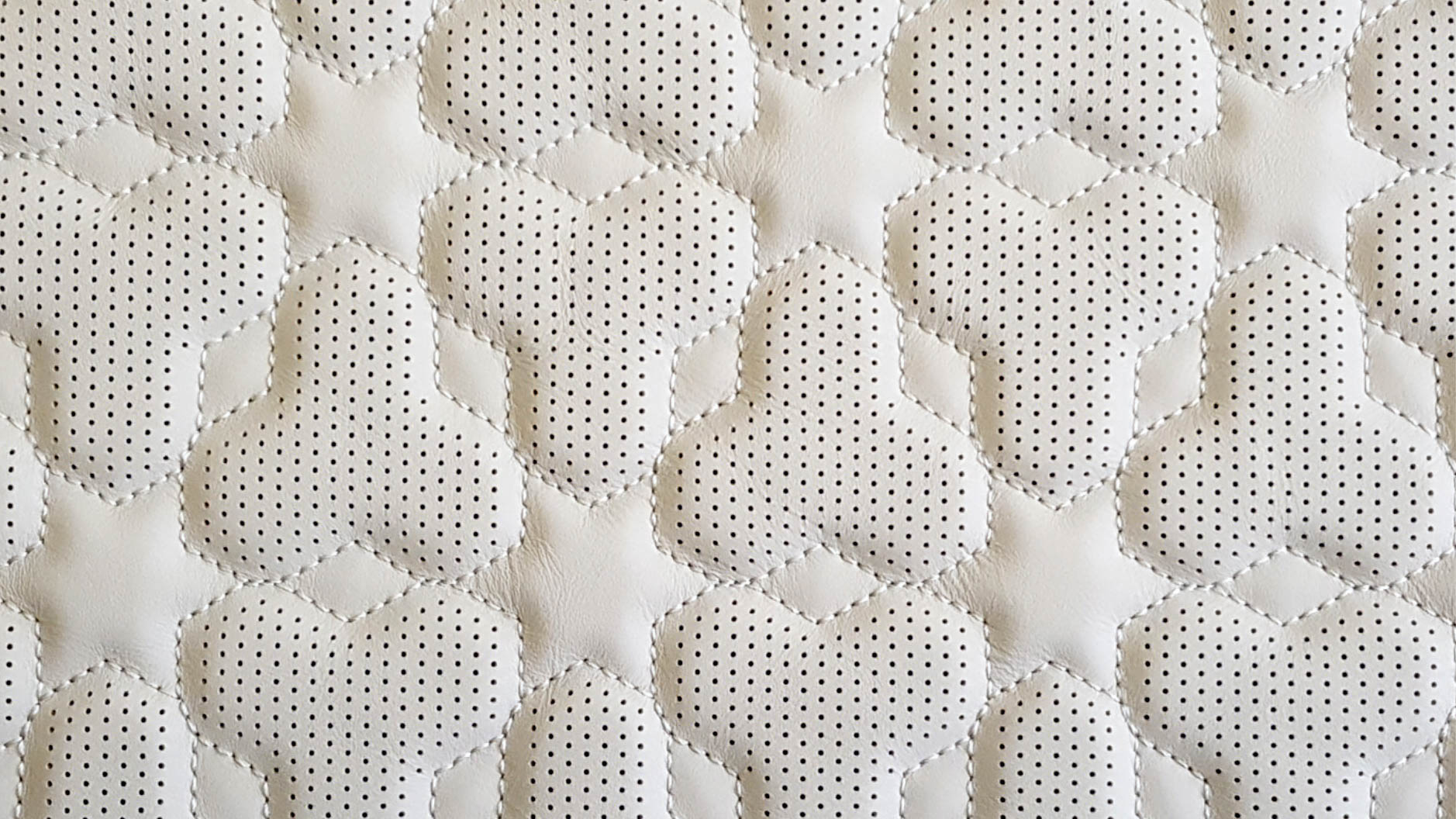

Combined with PAR, a machine specialized for perforation, it can create high-precision hole punching and quilt lines with minimal downtime.

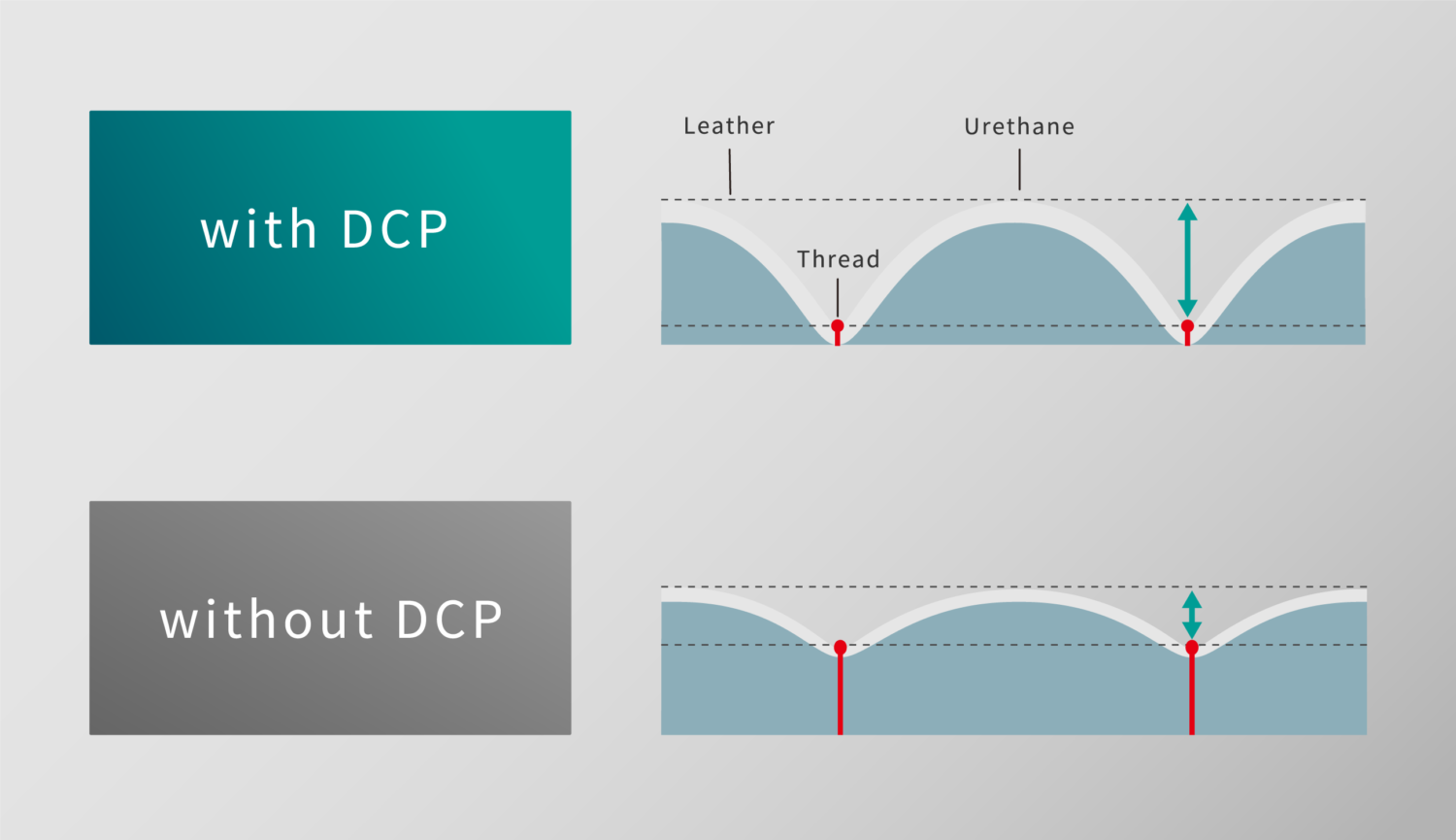

“DCP” for a Beautiful 3D Finish

Tajima's proprietary technology creates a greater 3D effect

When quilting leather and urethane together, in addition to automatic pressure application, fine-tuning through the control panel allows for firm sewing while pressing down on the elastic urethane. This eliminates loose threads and results in a high quality three-dimensional finish.

More about DCP

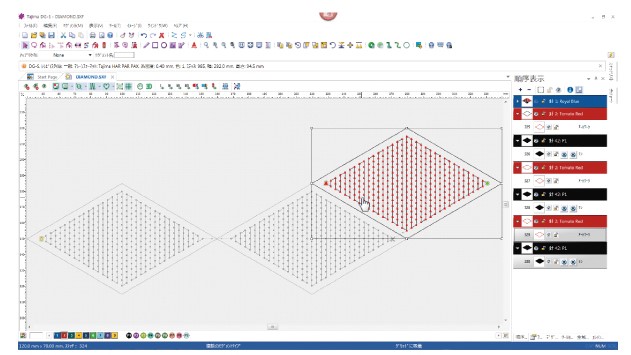

Maximize Design Reproducibility with Exclusive Software

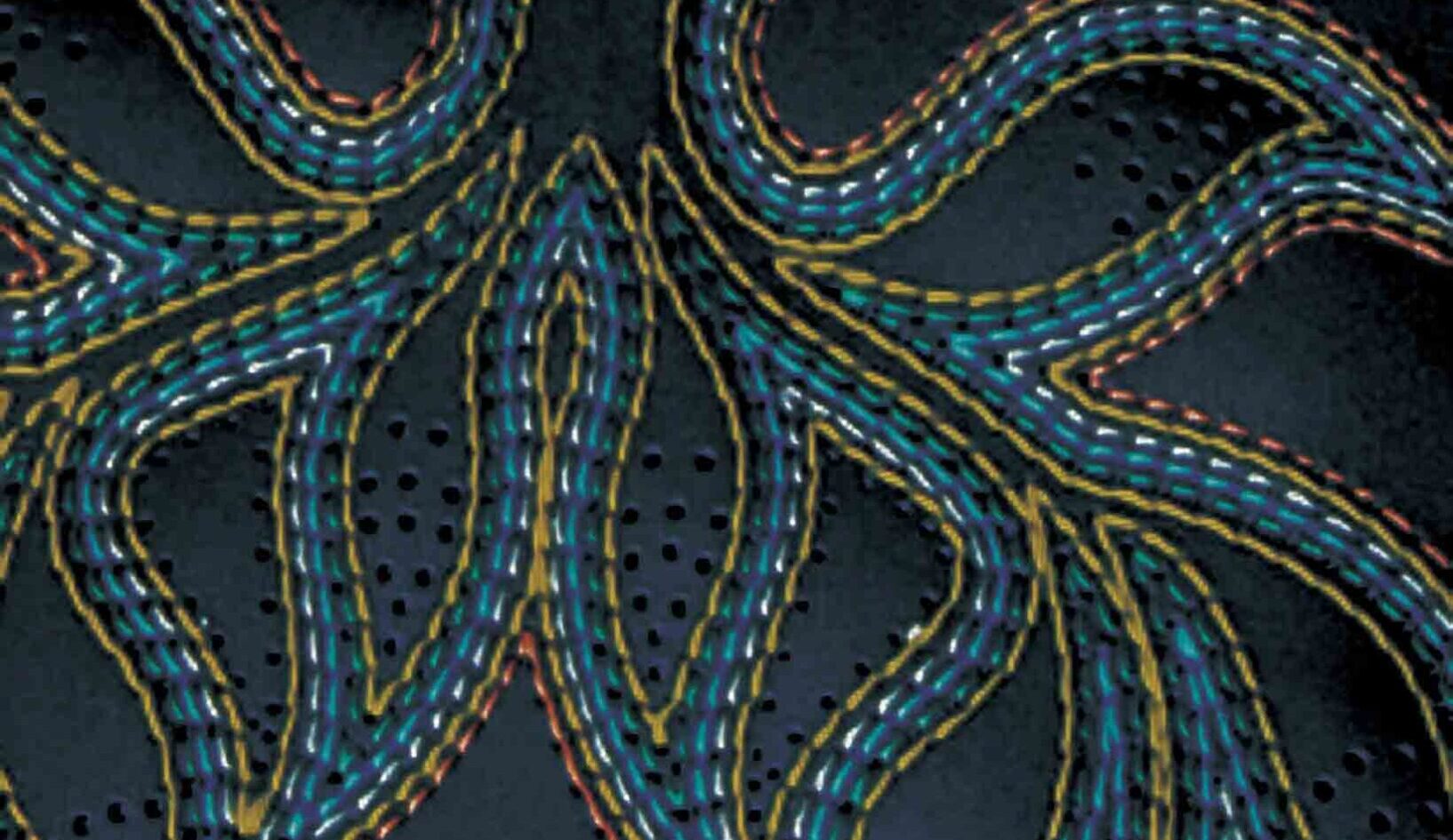

Committing the designer's imagination—just as it is—to data

“DG-S” design creation software can convert Illustrator and CAD data into perforation and sewing data, allowing designers to create patterns without limiting their imagination. Furthermore, creating patterns from data significantly reduces the cost and time that would be required for conventional mold manufacturing. It can also be adapted to small-lot production, where greater variety is required.

*DG-S design creation software is optional.

*Creation of embroidery data requires separate embroidery data software.

Tajima’s Customer Support Services

Sales in 160 countries and regions around the world.

We have delivered machines to 160 countries and regions and have a worldwide service network. Replacing embroidery machines or starting a new embroidery business? We apply Tajima’s proprietary AI technology and software in helping resolve our customers’ business issues. Please feel free to contact us through the CONTACT form.

HAR

HAR Product Specifications

| Model | H-head Sewing, Embroidery |

Needles | Work field (D×W) |

|---|---|---|---|

| HAR-V0901F | 1 | 9 | 750×800S mm 29.5×31.4 inch |

| 1,000×1,200S mm 39.3×47.2 inch |

|||

| HAR-V0902F | 2 | 9 | 750×800S mm 29.5×31.4 inch |

| 1,000×1,200S mm 39.3×47.2 inch |

*Maximum speed 1,100rpm

*Power supply

3-phase 200-240/350/380/400/415/440V 50/60Hz

Single-phase 200-240V 50/60Hz

*Power consumption Max.820w

*Embroidery speed varies depending on specifications, embroidery field,

and conditions of use (frame type, especially whether a frame is used or not, material, thread type, etc.).

Please contact your distributor for details.

Manufacturer Options Help Increase Production Efficiency and Safety

Gauge Frame

This eliminates any need to change the material during perforation, sewing, or embroidery, allaying concerns about misalignment.

Auto Bobbin Checker (ABC)

This feature detects if the remaining amount of bobbin thread is appropriate, preventing defects due to unexpected bobbin thread runout.

Bobbin Changer

Up to three bobbins can be pre-staged for replacement. This reduces the work in changing bobbins making extended embroidery operations more efficient.

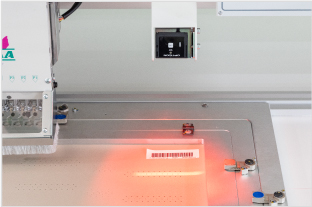

Barcode Reader

This function confirms that the design data coincides with the special gauge holding the fabric to prevent human error.

Beam Sensor

To help ensure safety, this sensor pauses the machine’s operation when an operator approaches a head while the machine is running.

Signal Tower

This allows machine operation to be detected even from a remote location.

Exclusive Presser Foot for Sewing Heads

The presser foot can be selected from 3 types according to the material type and the sewing method.

Thread Loosening Device

A device that reduces errors at the start of embroidery by loosening the tension on the upper thread during thread cut and stabilizing the cut surface.

Catalog Download

Use with Other Models to Optimize Mass Production and Prototype Development

Using HAR in combination with the specialized “PAR” perforation machine allows perforation, sewing, and embroidery to be carried out in parallel, thereby reducing downtime. For small lot production, prototyping, and development, we recommend the PAX series, which handles perforation, multicolor sewing, and multicolor embroidery on one machine. For more information, please contact us through the CONTACT form.

Distributors

TAJIMAG

Recommended content

-

Customer’s voice

Karimoku Furniture Inc.|Using PAX embroidery machines to add decorative touches to sofas.

-

Dialogue・Special feature

Tabio Co., Ltd. | Creating new value through embroidery. Producing one-of-a-kind socks, unique in all the world.

-

Customer’s voice

Kasamori Corporation | Enhancing Daily Life Through Embroidery. The Story of Developing a New Brand by Kasamori Corporation.