Motor driven type UBC units

UBC device consists of individual UBC units. They are driven independently which enables you to suspend only the troubled heads at the outbreak of a trouble. You can also select either all or alternate heads for operation on the Controller.

Controller & Head panels to control movement of the device

A controller to control the entire UBC device and Head panels to control each UBC unit are built-in.

It is now possible to start all the heads after bobbin replacement by a command on each Head panel and you do not need to move to the Controller.

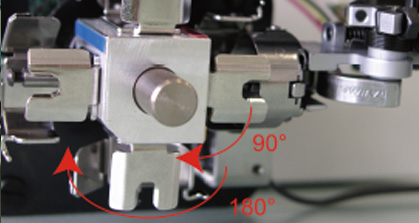

Selectable Bobbin cassette rotation (in 2 ways)

Select from either 2-pole (with 1 stock) or 4 pole (with 3 stocks) type bobbin cassette rotation.

2-pole type rotates 180° while 4-pole type rotates 90° for bobbin replacement to match with your application.

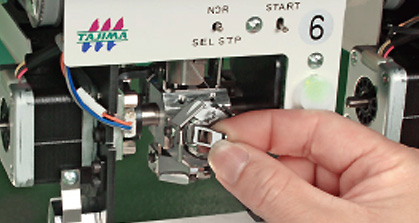

User-friendly function to Assist replacement of under bobbins

A buzzer will sound to tell you when it is time to replace an empty bobbin.

Empty bobbins come forward using a switch operation for easy replacement.

- This function is available only for 4-pole rotation type.

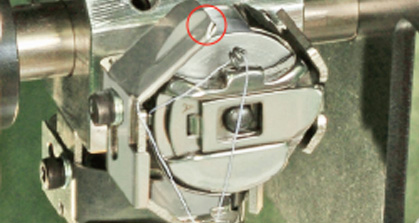

Under thread holding mechanism to prevent stitch starting error

The tail length of under thread is held at the equal length by a knife to prevent stitch starting error. The tail length of under thread is variable by adjustment of the knife.

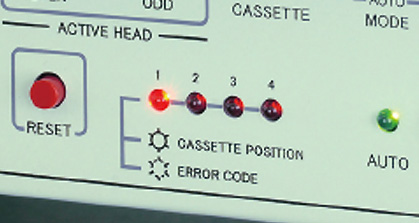

LED display function to minimize time loss

At the occurrence of an error LED will blink on the related Head panels.

Moreover, the LED on the Operation panel will display the error code so that you can check the cause of the error immediately.