Accelerate DX in embroidery supply chain

to increase productivity and Reduce errors and losses

Many processes in PulseID, including ordering, data generation, product pickup, setting up the embroidery machine, shipping, and delivery require human labor. Implementing PulseID allows you to handle more orders, and without mistakes. Additionally, PulseID visualizes data for factories’ operating status and operator productivity, providing more efficient factory operations and solutions to professional environment issues.

Tajima’s unique cloud technology

improves the efficiency of embroidery service operations

What is PulseID(DG.NET SaaS)?

"PulseID" advances the embroidery supply chain's digital transformation

PulseID is a system that handles everything from automatic creation of embroidery data to data transfer, production status, and report creation. PulseID allows you to evaluate production efficiency through visualization of the embroidery machines’ operating status.

Cloud services reduce the costs of adopting the system and allows implementation in less time.

Benefits of PulseID

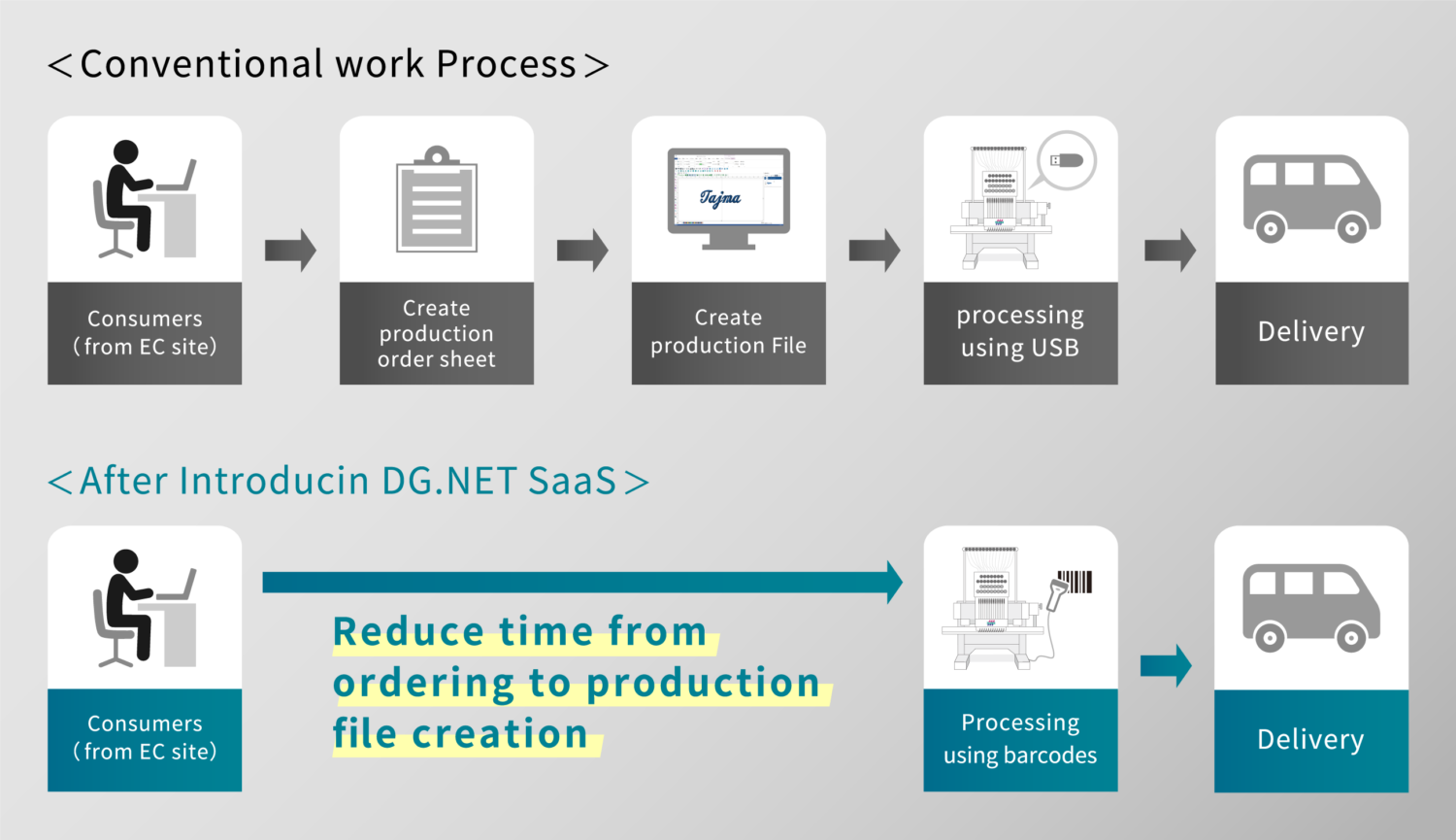

Significantly simplifies workflows

Embroidery data is automatically created when an order is made on the e-commerce site, with the embroidery data and work specifications being sent to the cloud server at the same time the order is sol omitted. These are linked to barcodes, where the linked factories and operators can simply scan the barcodes to transfer the information necessary for production to the embroidery machines. Simplifying the embroidery workflow system this way significantly reduces lead time, and allows businesses to accommodate larger numbers of orders, and shortens delivery times.

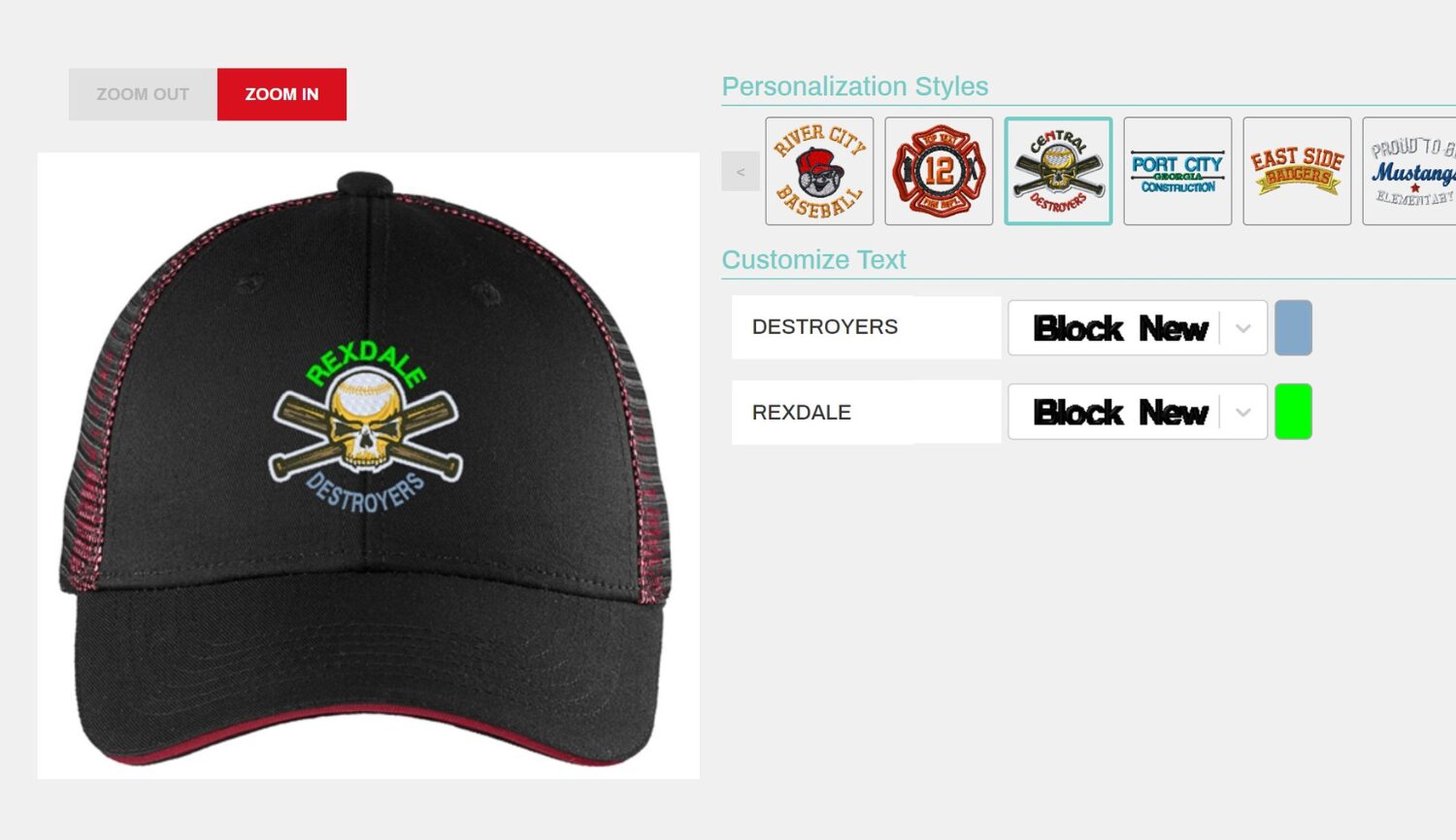

Automatically generates and previews embroidery data

Embroidery data on e-commerce sites is automatically generated and rendered as 3D previews. This prevents ordering errors and issues with the product differing from the customer’s vision. Another advantage is the enjoyment that customers derive in choosing the designs.

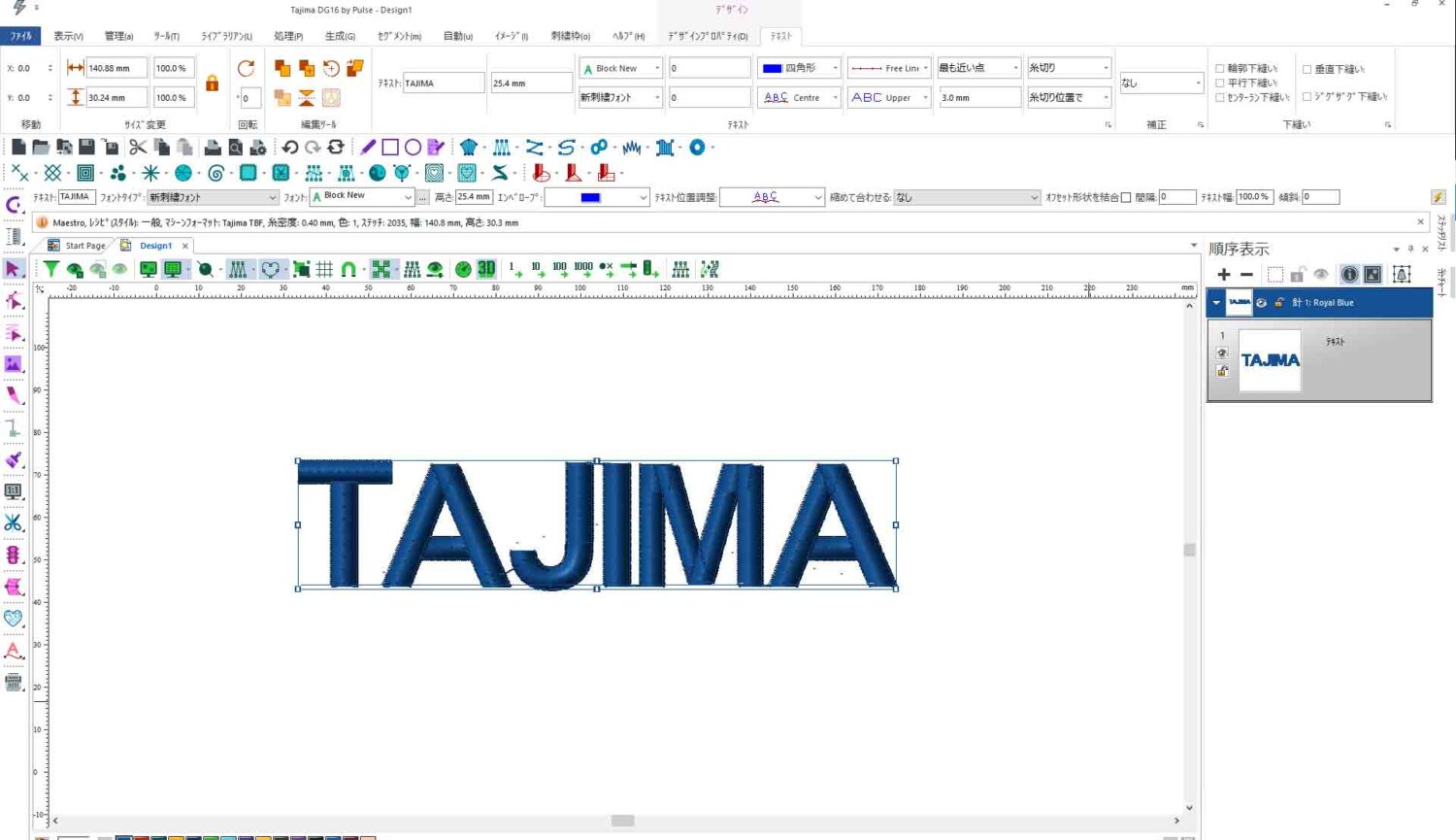

Embroidery data is immediately transferred to production

The accurately generated data is saved on the server along with thread colors and other information and put in standby. This greatly shortens preparations before production.

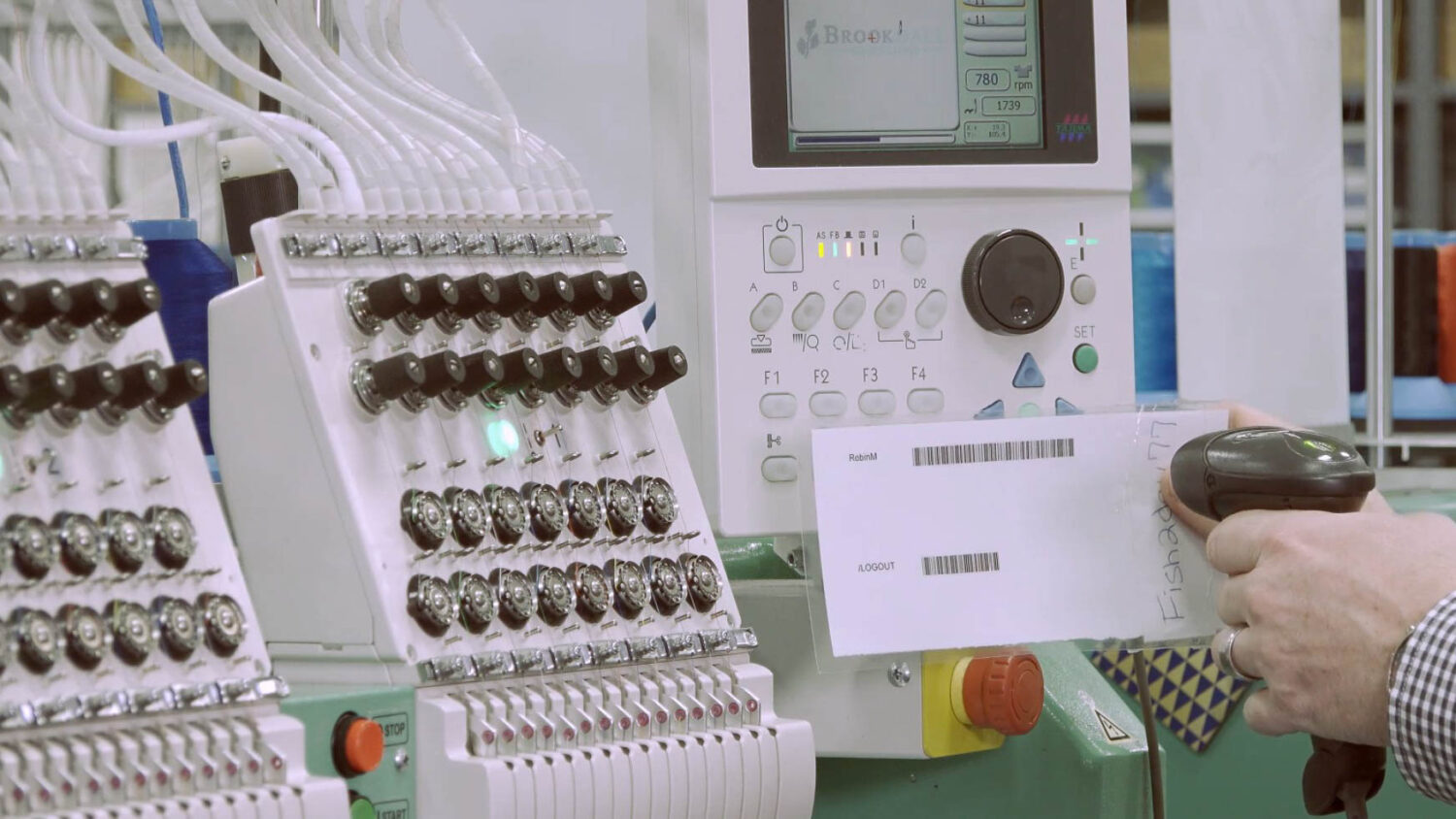

Data is transferred with barcodes

With a single scan, all of the data necessary for production is transferred to the embroidery machine. This reduces the steps of selecting the data and setting the machines while also preventing human errors such as mistakes in registration.

Benefits of PulseID

Visualizes factory operations and increases productivity

The PulseID system handles everything from automatic creation of embroidery data to data transfer, production status, and report creation. Remote check of factory operating status and other functions enable more efficient factory operations. The report function included with the system can be used to visualize the operating rate and production volume data for each operator individually, which is useful in improving training and factory operations.

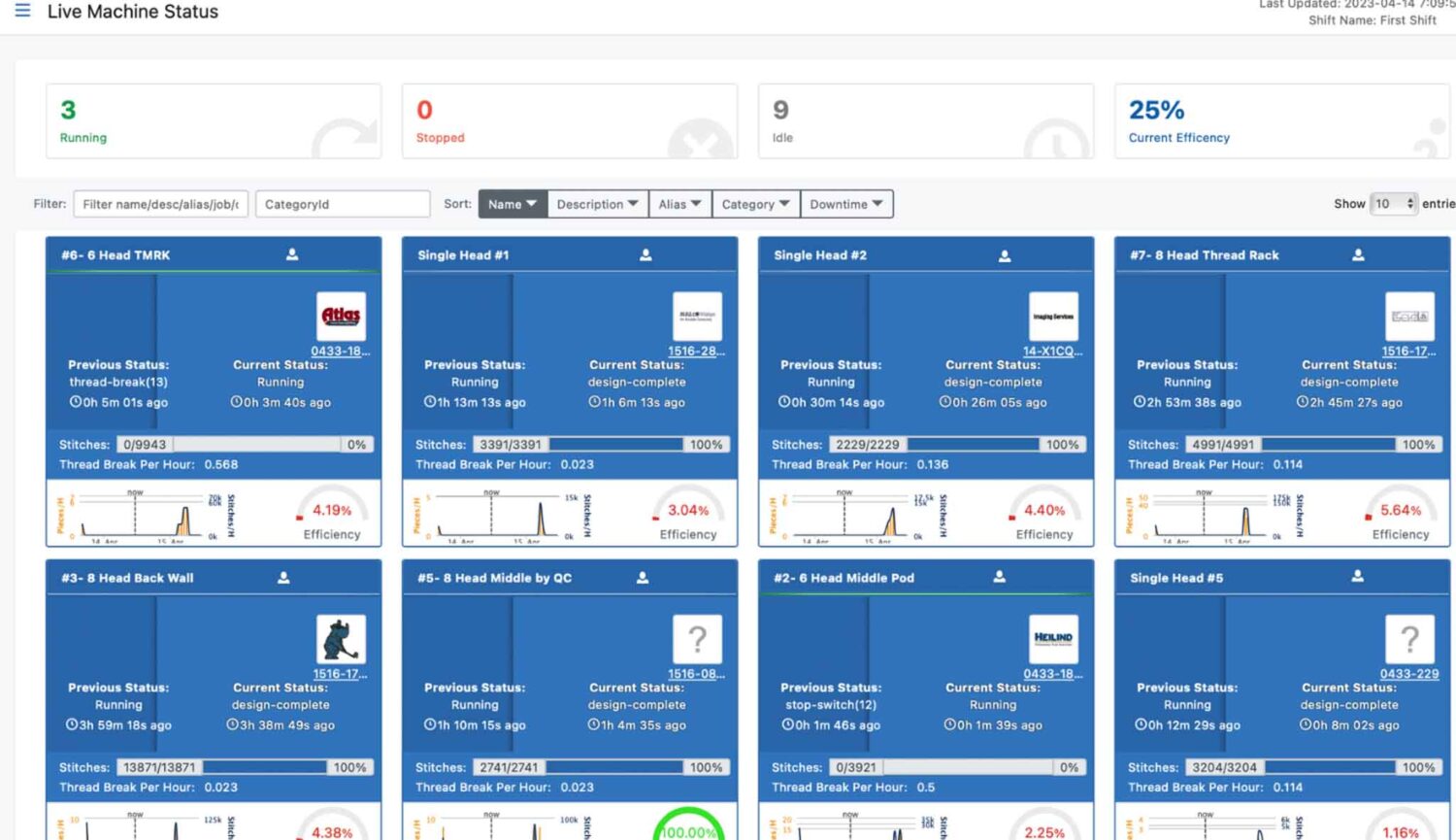

Checks operating status

Data on production progress for the entire factory and issues with each individual embroidery machine can be collated and checked remotely. Production at multiple locations in different countries can also be centrally managed.

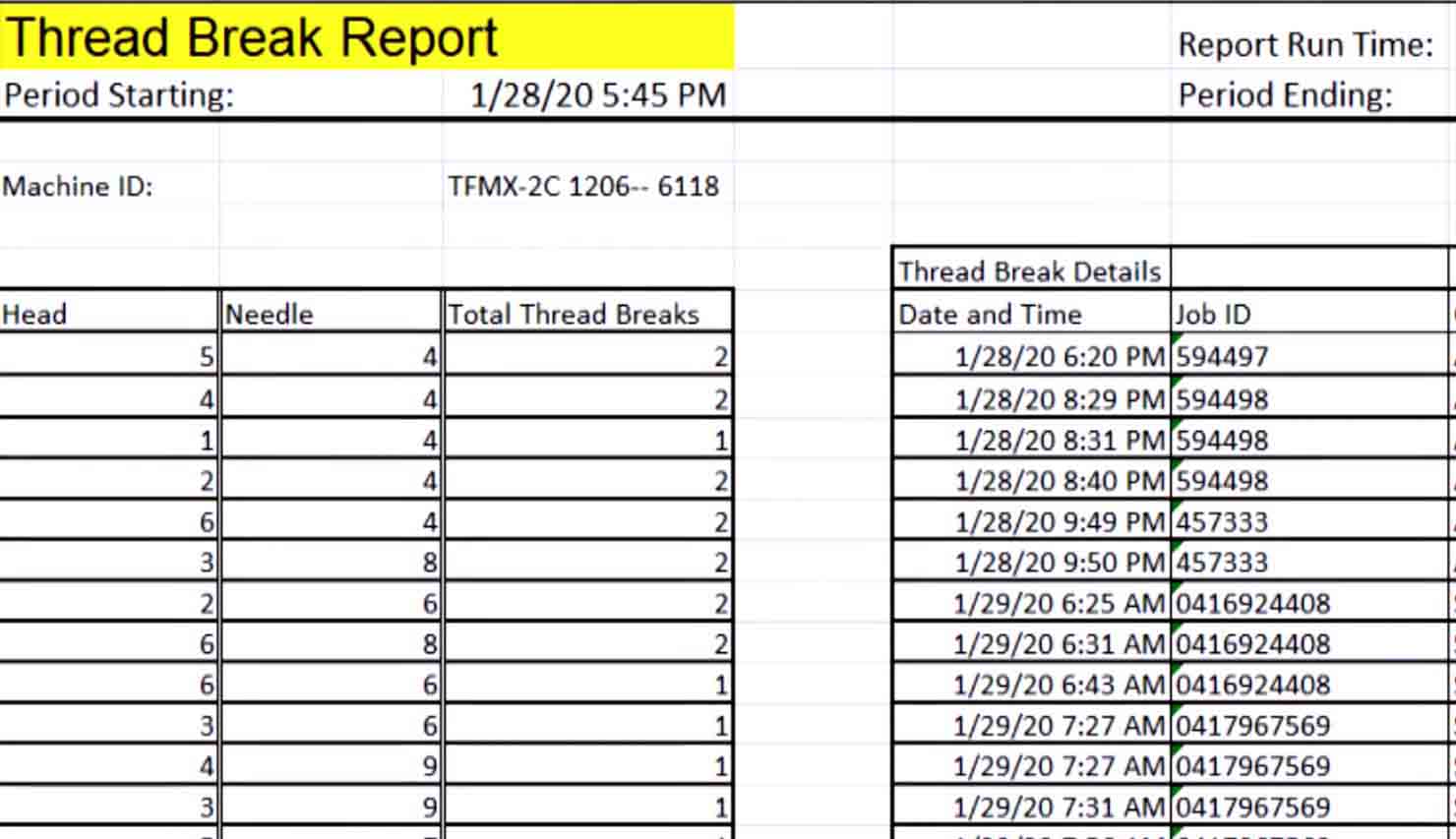

Generates reports automatically

The system automatically creates reports from the aggregated production data. It also can output customized data, a useful feature in confirming progress, calculating payrolls, and other tasks.。

Consistent embroidery production quality with AI embroidery machines

Operators revenue skill in adjusting the upper thread, a major factor influencing the embroidery finish. With an embroidery machine equipped with Tajima’s “i-TM,” the AI can control the upper needle thread tension adjustment automatically. The system automatically programs the optimal settings in accordance with the thread type and fabric, so even inexperienced operators can easily create high-quality embroidery.

Recommended Products

-

Embroidery Software

PulseID(DG.NET SaaS)

System provides comprehensive support for the embroidery supply chain, from receipt of orders to production

-

-

Embroidery machine|Single-head Cylinder Type

TMEZ-SC

Single-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery machine|Multi-head Cylinder Type

TMEZ-KC

Multi-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-