Tajima’s abilities in providing total solutions helps

resolve problems at production sites

It is said that a declining birthrate, aging population, shifting lifestyles, and other recent societal changes are making it difficult for companies to secure workers, and the embroidery industry is no exception. As veteran craftsmen retire and various other factors come into play, securing highly skilled operators has become a struggle, making this a serious problem for manufacturing sites. Tajima offers solutions that enhance the efficiency of embroidery businesses’ factory operations, with more stable production of high-quality embroidery, visualization of production information, and suggestions for embroidery machines and software that are tailored to the customer’s business.

High-quality and stable sewing using AI technology “i-TM” and “DCP”

-

"i-TM" AI embroidery technology

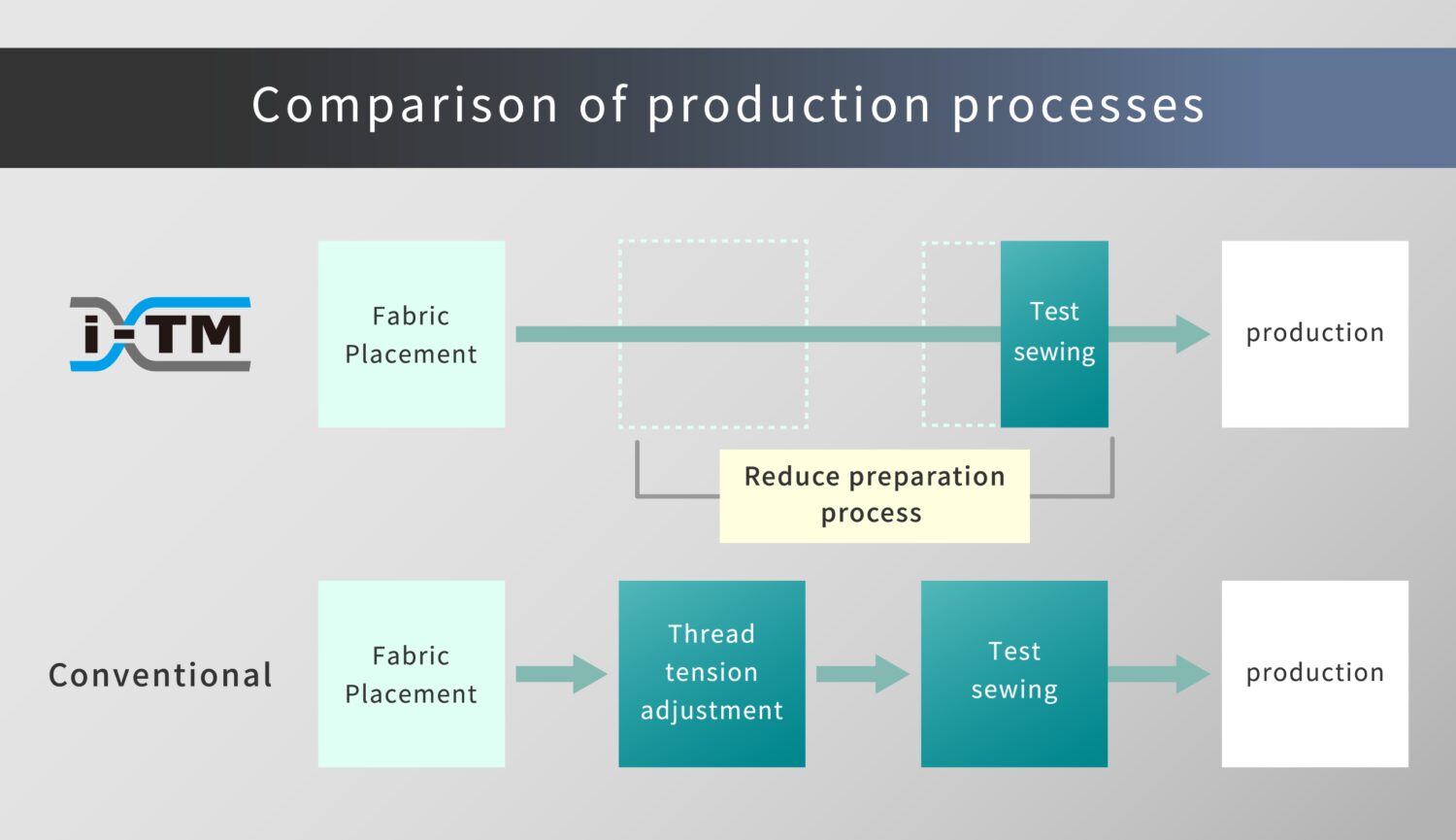

The AI function “i-TM” controls the upper thread, significantly reducing the time required for the “adjustment process” for adjusting the upper thread before test sewing or full production.

See more

Compared to conventional tension adjustment, i-TM places less burden on the thread, reducing the frequency of thread breakage and allowing the machine to increase the number of revolutions without worry. Productivity is improved by approximately 30% compared to conventional machines. (According to our own research). Maximize per capita production.

-

"DCP" Digitally Controlled Presser Foot

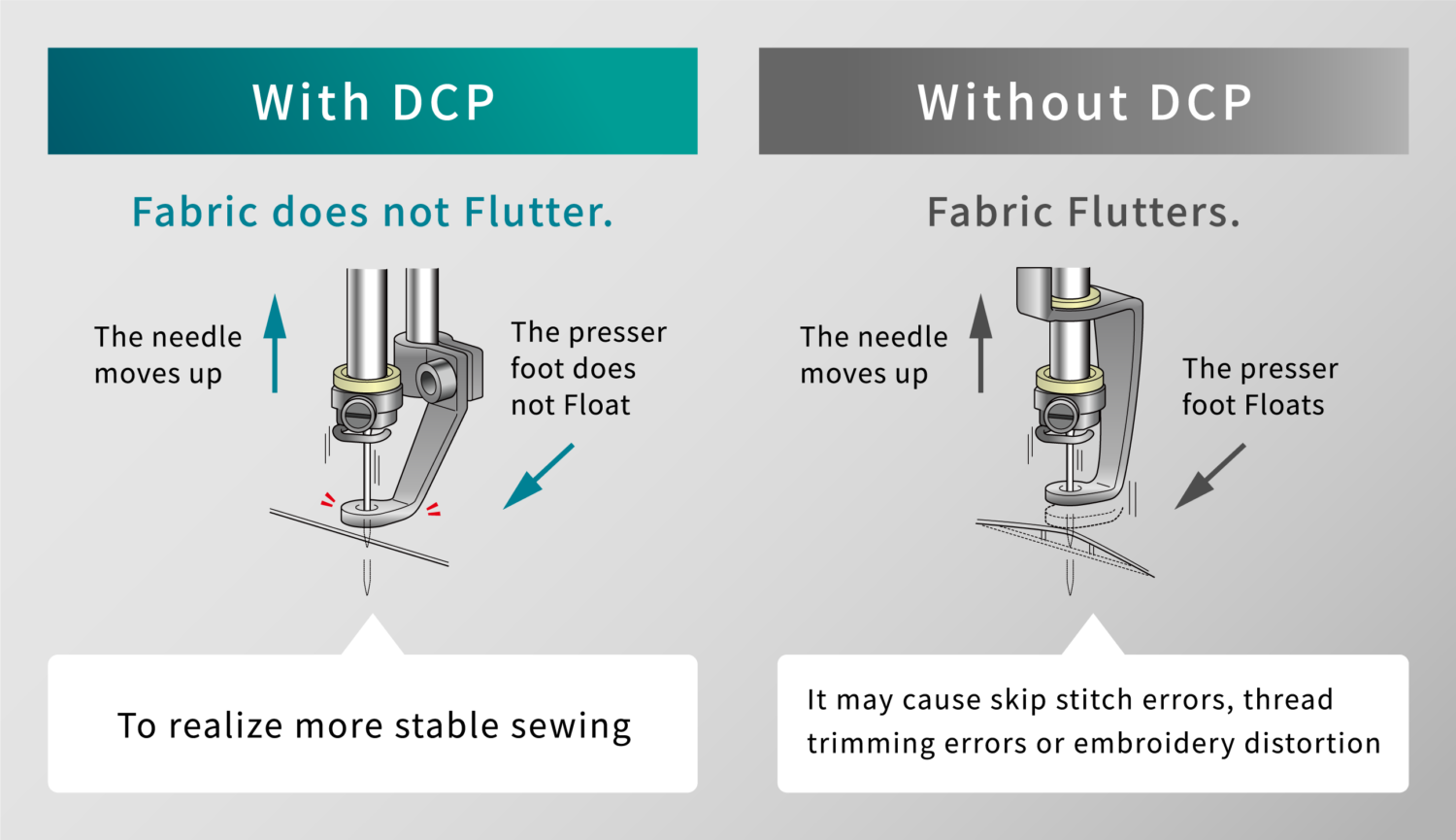

DCP technology uses digital control to hold the fabric down.

See more

DCP reduces fabric fluttering, which causes skipped stitches, thread trimming errors, and unevenness in embroidery. DCP also results in more stable sewing.

Visualize production data with PulseID for more efficient factory operations

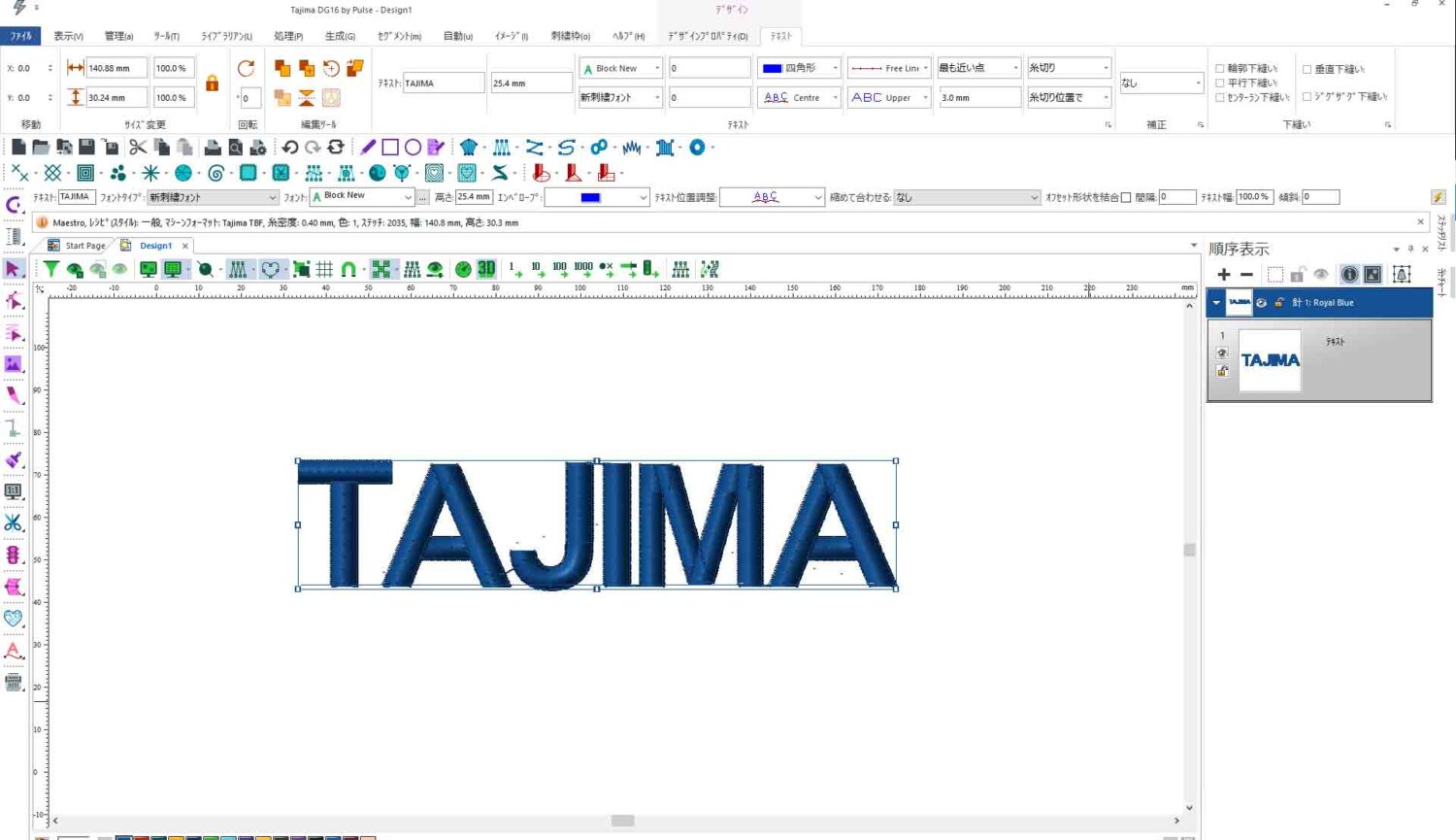

What is PulseID(DG.NET SaaS)?

"PulseID" Facilitates DX in Embroidery Supply Chain

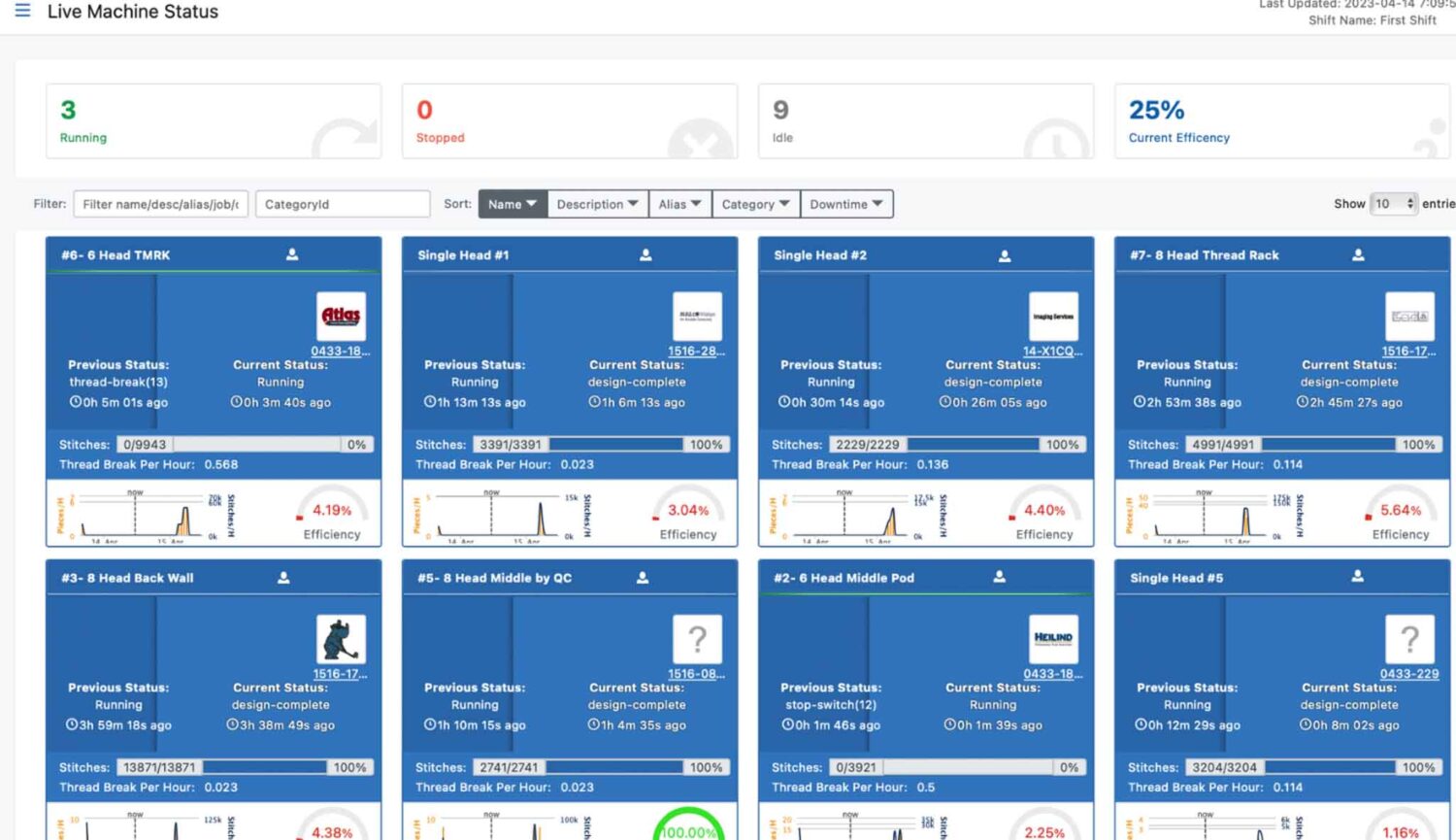

PulseID is a system that handles everything from automatic creation of embroidery data to data transfer, production status and reporting. Production efficiency can be evaluated by visualizing embroidery machine operation and production status.

Benefits of PulseID

Factory Visualization

Production progress of the entire factory and trouble information for each embroidery machine can be checked remotely, enabling centralized management even when production is carried out at multiple sites across the country. Reports can also be automatically generated from the aggregated production information. Customized output of necessary information is also possible, which is useful for checking the progress of production.

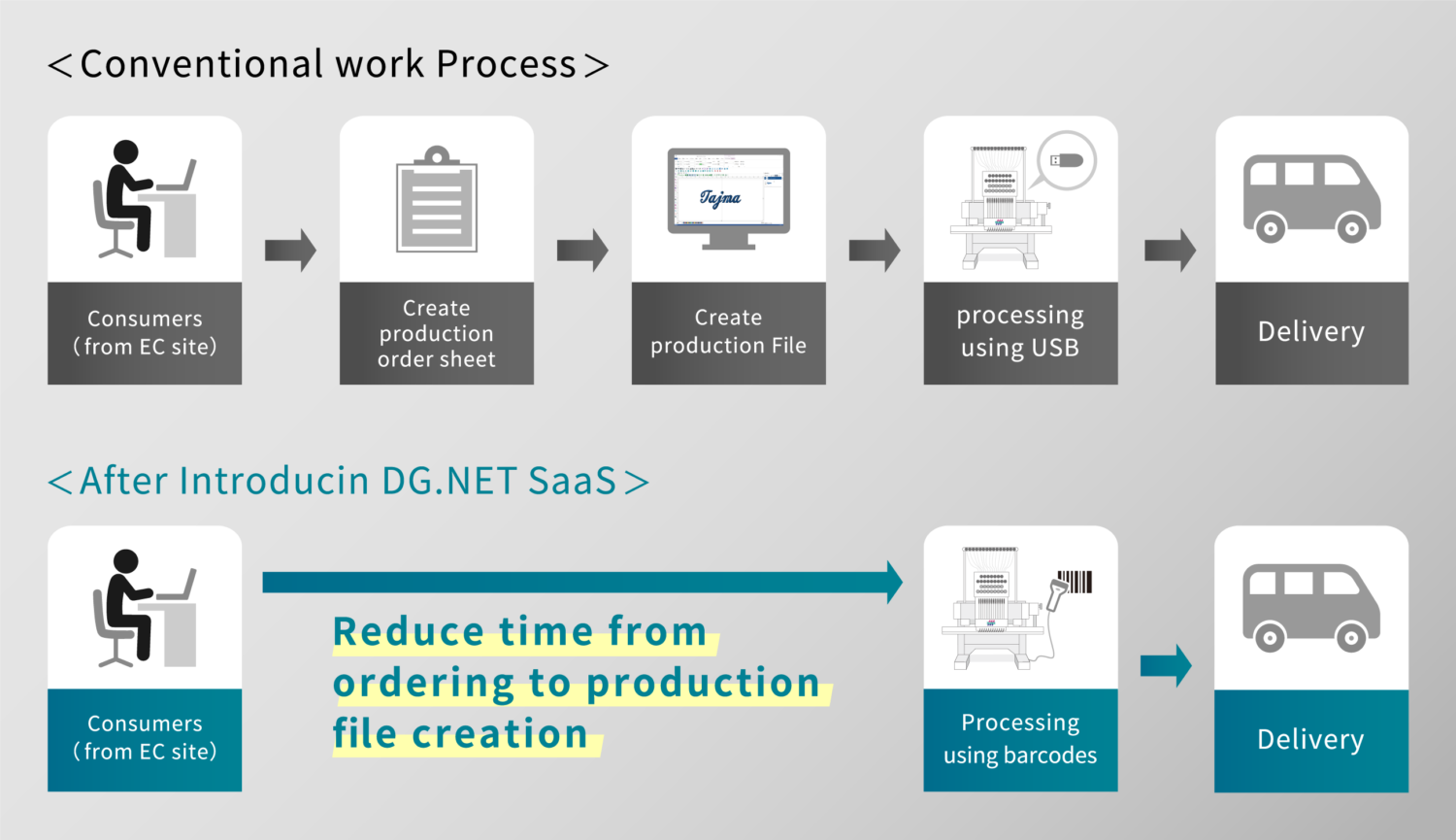

Significantly reduced lead time for embroidery production

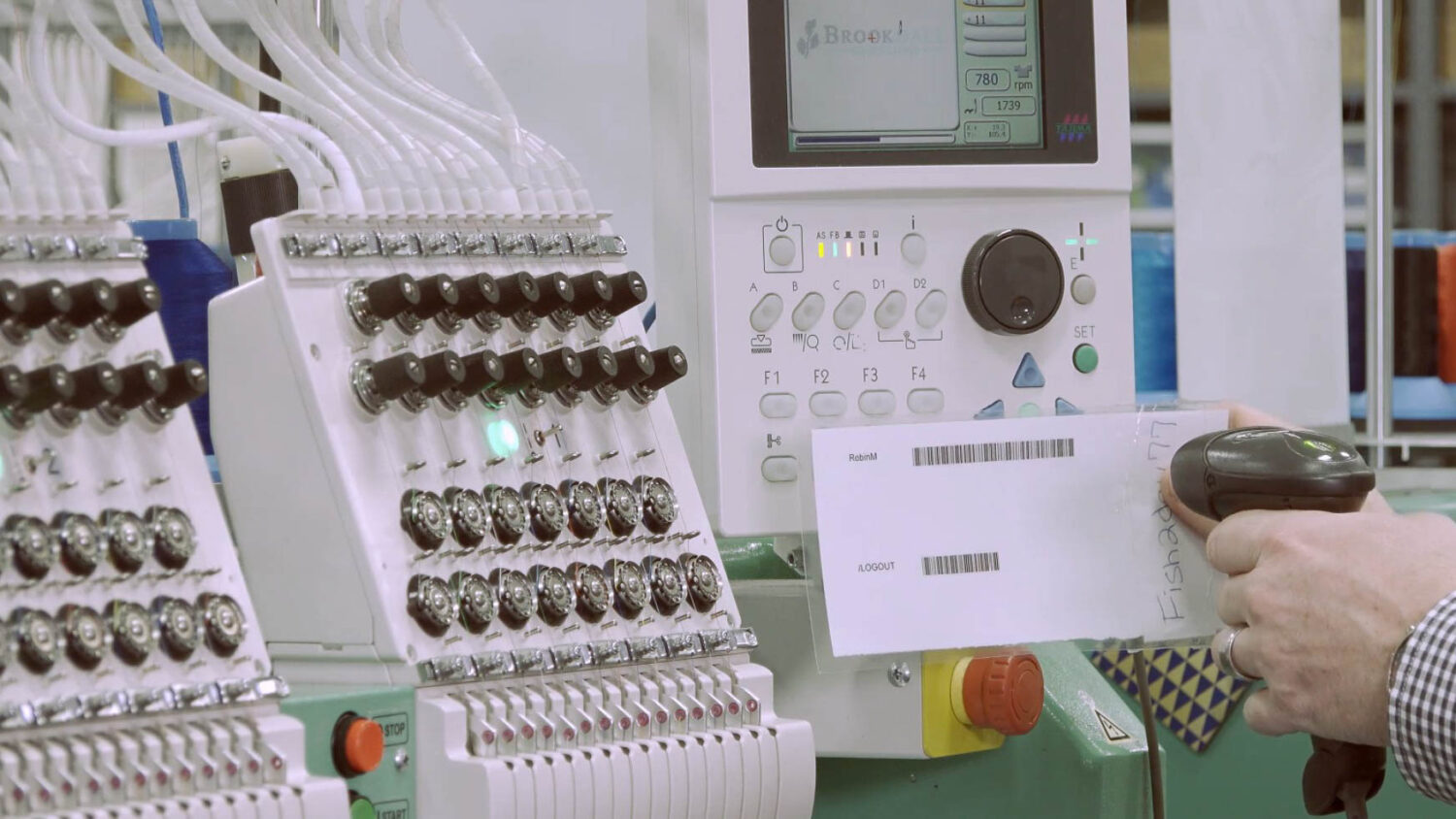

Embroidery data is automatically created when an order is placed on the e-commerce site, and embroidery data and work specifications are sent to the cloud server as soon as the order is completed. When the operator scans the barcode to which they are linked, the information necessary for production is transferred to the embroidery machine. By simplifying the embroidery workflow through the system, lead time can be significantly reduced.

Features of PulseID

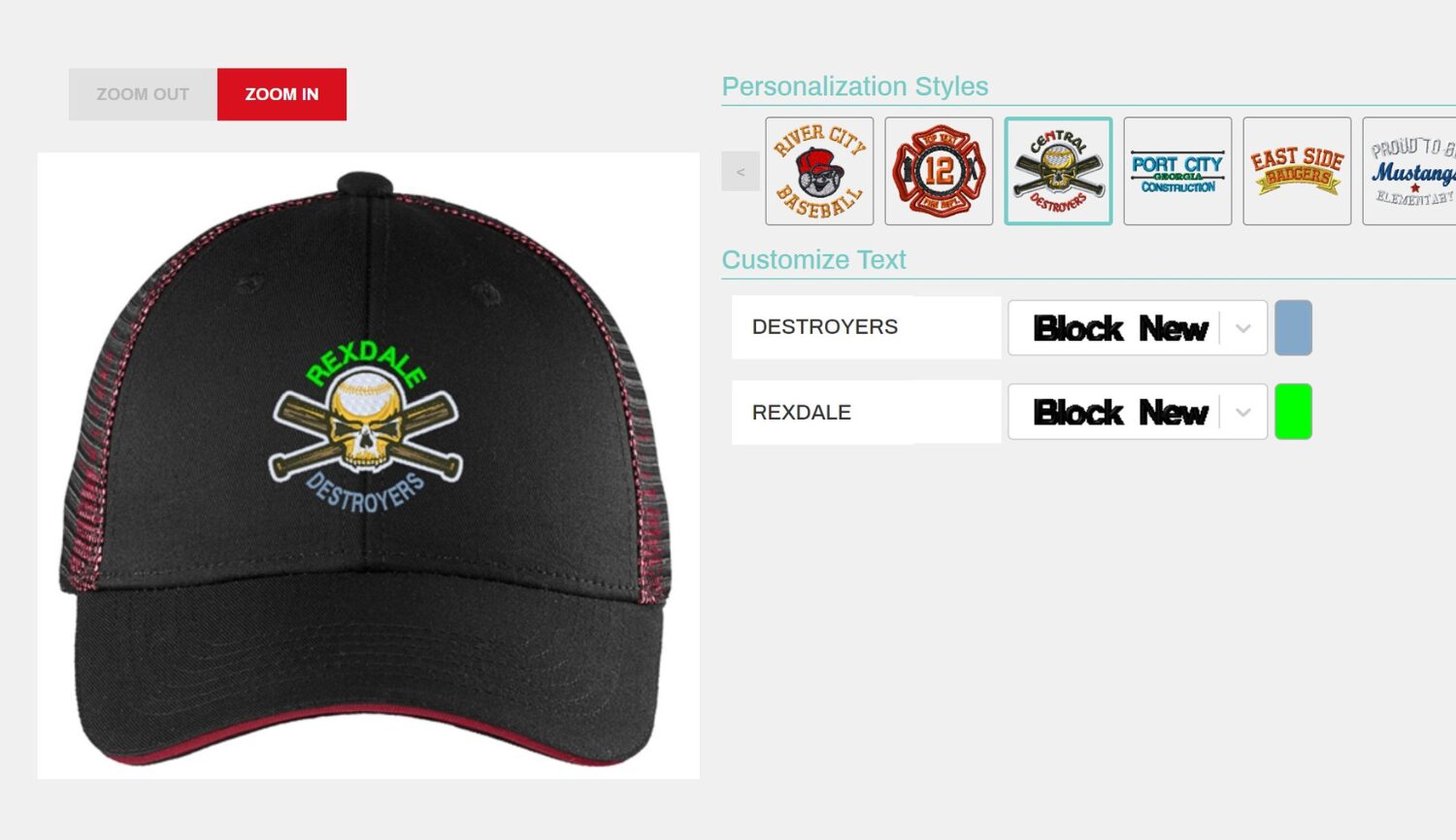

Automatically generates and previews embroidery data

Embroidery data on e-commerce sites is automatically generated and rendered as 3D previews. This prevents issues with the product differing from the customer’s vision. Another advantage is the enjoyment that customers derive in choosing the designs.

Embroidery data is immediately transferred to production

The accurately generated data is saved on the server along with thread color and other information, and the data then ready in standby. This greatly shortens the preparatory steps before production.

Data is transferred with barcodes

With a single scan, all of the data necessary for production is transferred to the embroidery machine. This reduces the steps of selecting the data and setting the machines while also preventing human errors such as mistakes in registration.

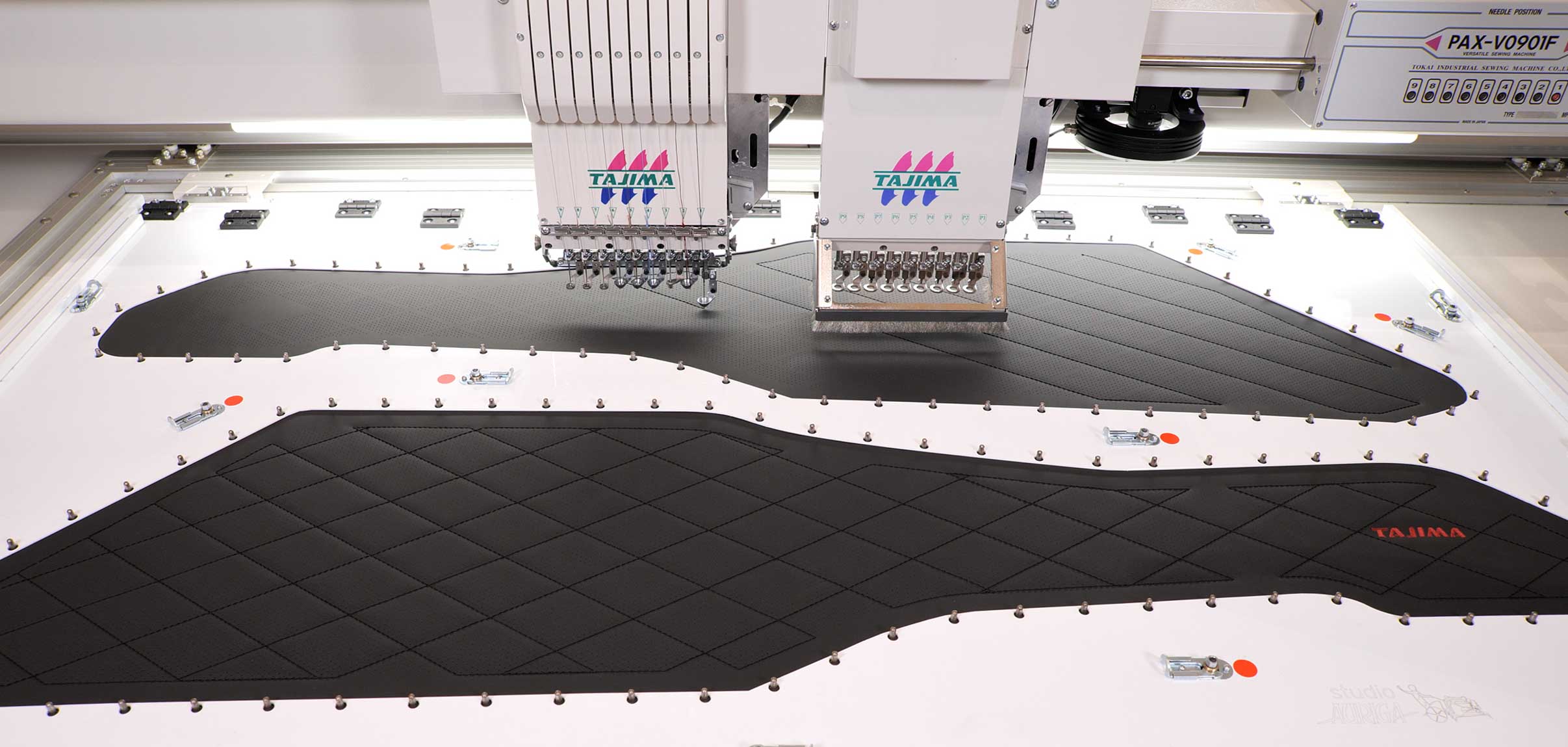

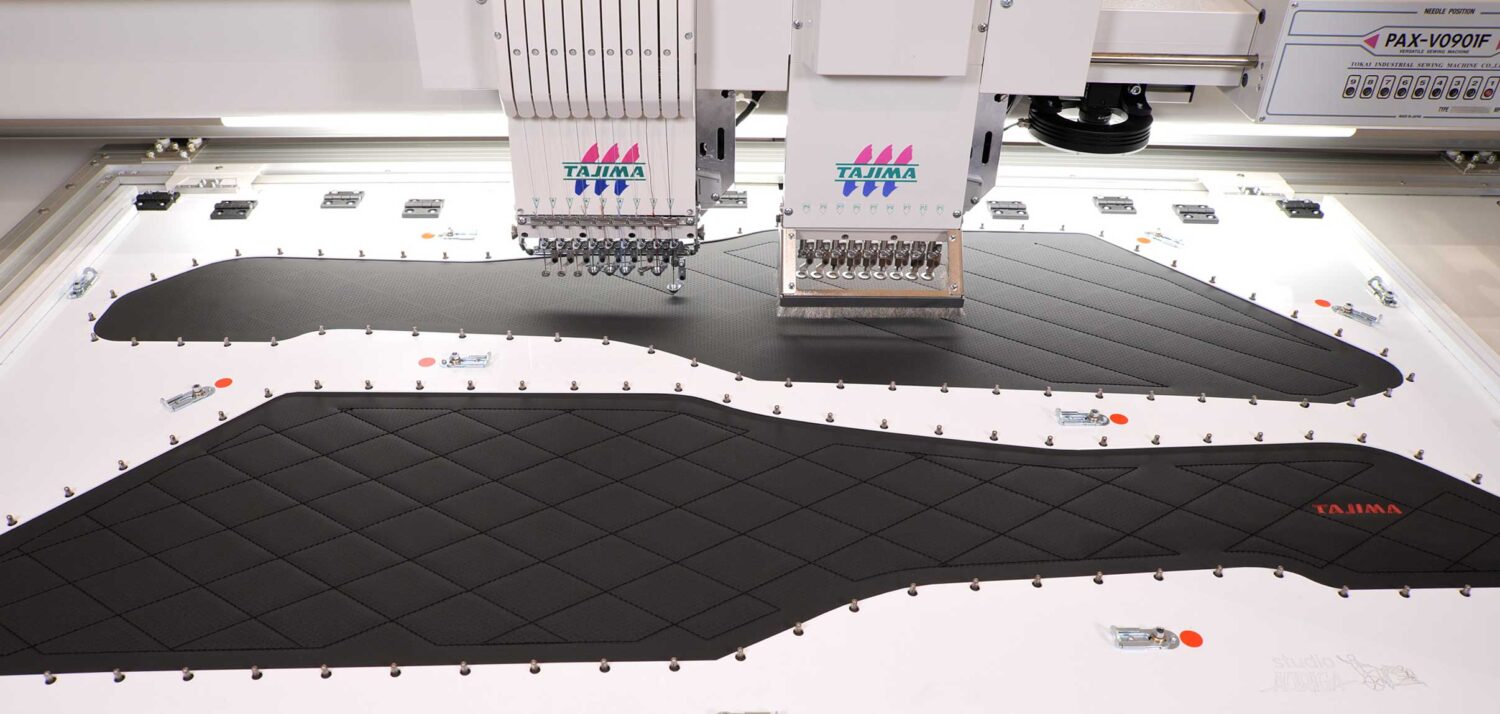

Shortening production flow with perforation, multicolor sewing, and multicolor embroidery, all in a single machine

PAX can perform perforation, sewing, and embroidery, all in this one machine. It offers outstanding support in small lot production, prototyping, and development. In addition, there is no need to realign the material, and with the perforation, sewing, and embroidering settings programmed just once, there are no concerns about displacement of the designs, nor is there any need to switch large frames or assign different operations to multiple machines. This results in an efficient production system that reduces operator workloads.

Perforation, sewing, and embroidery can be performed together, without replacing the material.

There is no need to use separate machines for large products such as furniture, curtains, and car seats, making this a very operator-friendly system.

Providing the best solution for your business

We propose embroidery machines and software that best suit your business, including the items to be produced, location of the factory, and deployment of operators. We offer comprehensive support for your embroidery business by providing total solutions, including not only an extensive lineup of embroidery machines with the right number of heads, needles, and specifications, but also embroidery data creation software and “PulseID” for DXing your factory operations. Please feel free to contact us.

Recommended Products

-

Embroidery machine|Multi-head Flat Type

TMCR-VF+i-TM

Multi-head Flat Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery Software

PulseID(DG.NET SaaS)

System provides comprehensive support for the embroidery supply chain, from receipt of orders to production

-

-

Multi-perfect sewing machine

PAX

Perforation, multicolor sewing, and embroidery, all in one machine. Suitable for leather processing.

-