Changing the mindset about production and consumption,

bringing about a society that protects the Earth.

In building a sustainable society, we have a responsibility to provide the next generation with a prosperous future, a duty that will become increasingly important in the future. Approaches to production and consumption are now entering a new phase, and we at Tajima aim to use our embroidery technologies in helping solve problems such as reducing waste and inventory.

Contributing to an environmentally friendly society by reducing production loss

Embroidery of finished products

Cylinder-type machines for embroidering cylindrical items can be used to embroider finished products such as clothing and hats.

Adding embroidery only as the customer orders it eliminates the need to keep inventory for each variation. We are making the concept “make only what’s used” a basic principle of production.

Reduce production loss with AI embroidery machines

Use of AI embroidery machines enables stable production of high-quality embroidery, regardless of the operator’s skills and abilities. Stabilizing production reduces the occurrence of defective products and cuts production losses.

Personalized embroidery results in products suited to each individual customer

PulseID facilitates ethical consumption

Personalized embroidery delivers a highly satisfying purchasing experience. Products that feature personalized embroidery incorporate the customer’s unique style and will be used and cherished and for years to come.

Embroidery gives us an opportunity to consider what ethical consumption is.

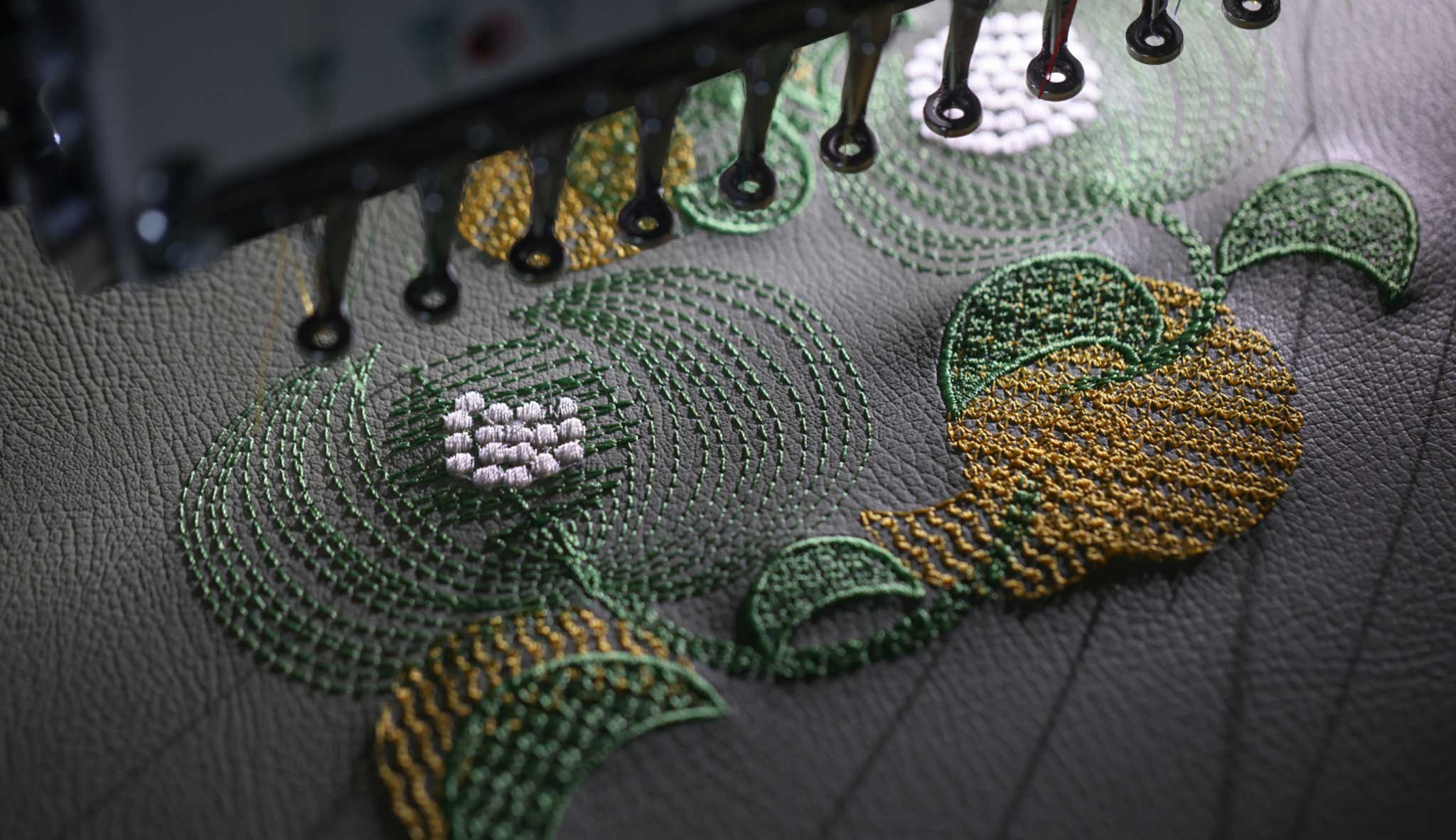

Creating beautiful embroidery, with sustainable materials

We have also seen an increasing number of examples of ethical materials being used as a sustainability initiative. Tajima’s AI embroidery machines adjust automatically to create beautiful finishes, including the use of plant-based vegan leather and thread made from recycled materials.

Reducing environmental impacts with light,

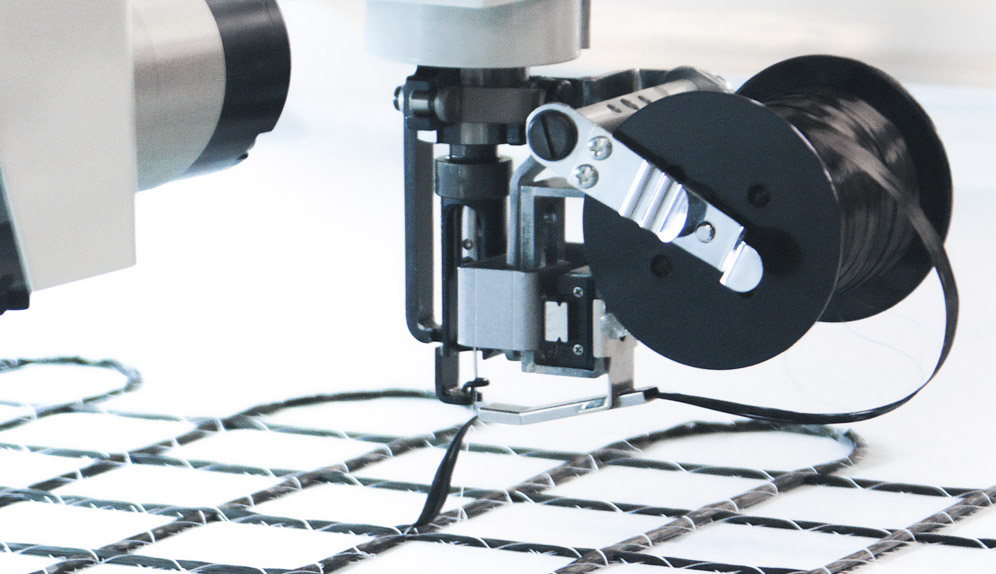

strong carbon materials

The need to improve fuel efficiency and reduce CO2 emissions has resulted in is a growing need for carbon fiber, which is lighter and stronger than metal and now widely used in aircraft and automobiles.

We have been utilizing Tajima’s embroidery technology to maximize the potential of reinforced fiber materials, surpassing the results derived with conventional process (e.g., unidirectional tape), enabling the manufacturing lighter, more durable products. In addition, the new technology outdoes conventional methods for yield rate during the production process, and materials can be used without waste. Transcending the boundaries of apparel, embroidery technology is now also being used in industry to achieve environmentally friendly processing.

TFP process

The TFP process can be used not only with carbon fibers, but with plant-based fibers as well. Use of bioplastics and other sustainable materials makes it possible to create products made from 100% bio-based materials.

More about TFP process

Recommended Products

-

Embroidery machine|Multi-head Cylinder Type

TMEZ-KC

Multi-head Cylinder Type Flagship Model is equipped with Tajima's latest technologies

- Flagship

-

-

Embroidery Software

PulseID(DG.NET SaaS)

System provides comprehensive support for the embroidery supply chain, from receipt of orders to production

-

-

Special machine

TCWM

Specialized composite fiber sewing machine for attaching reinforced fibers

-