Evolution of Preform Manufacturing

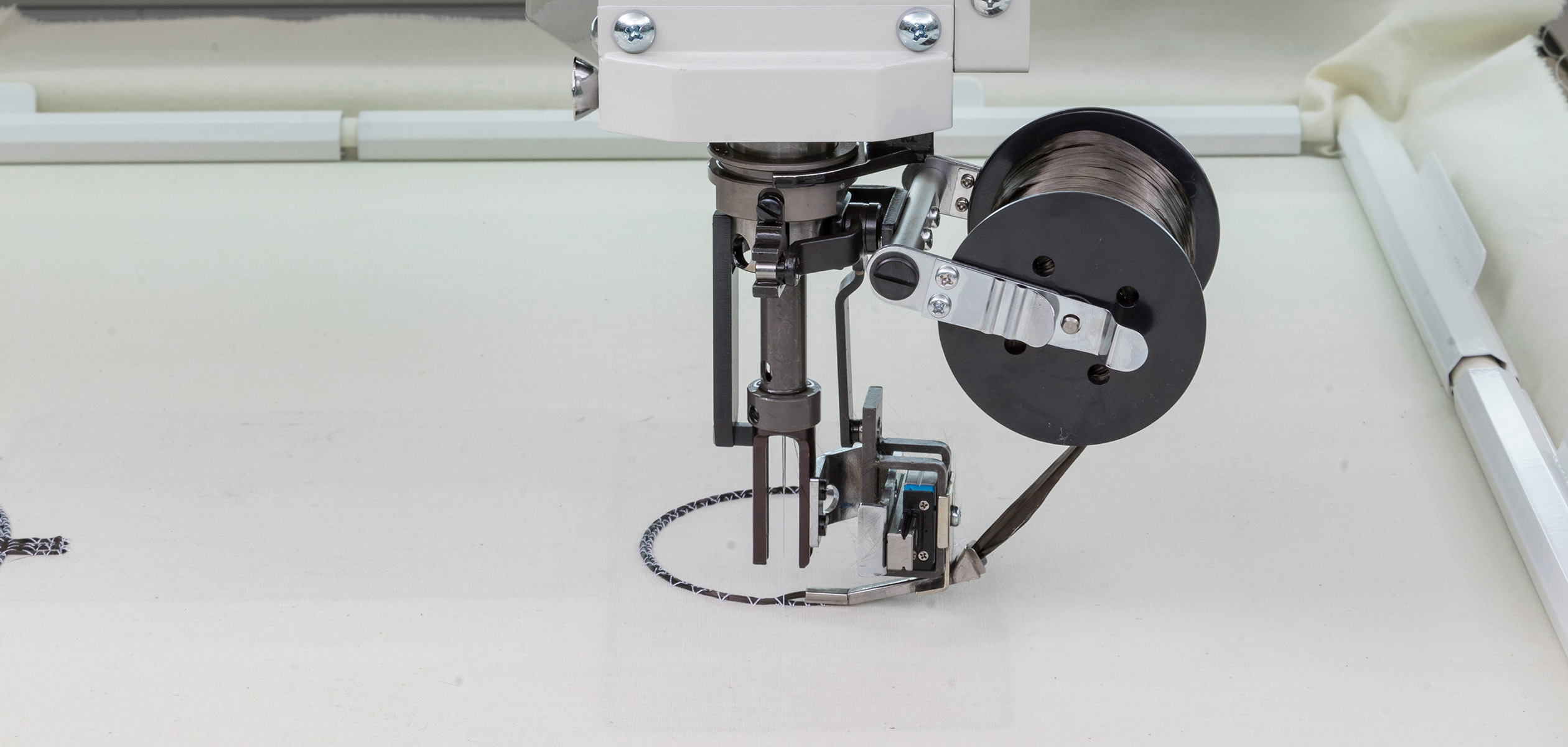

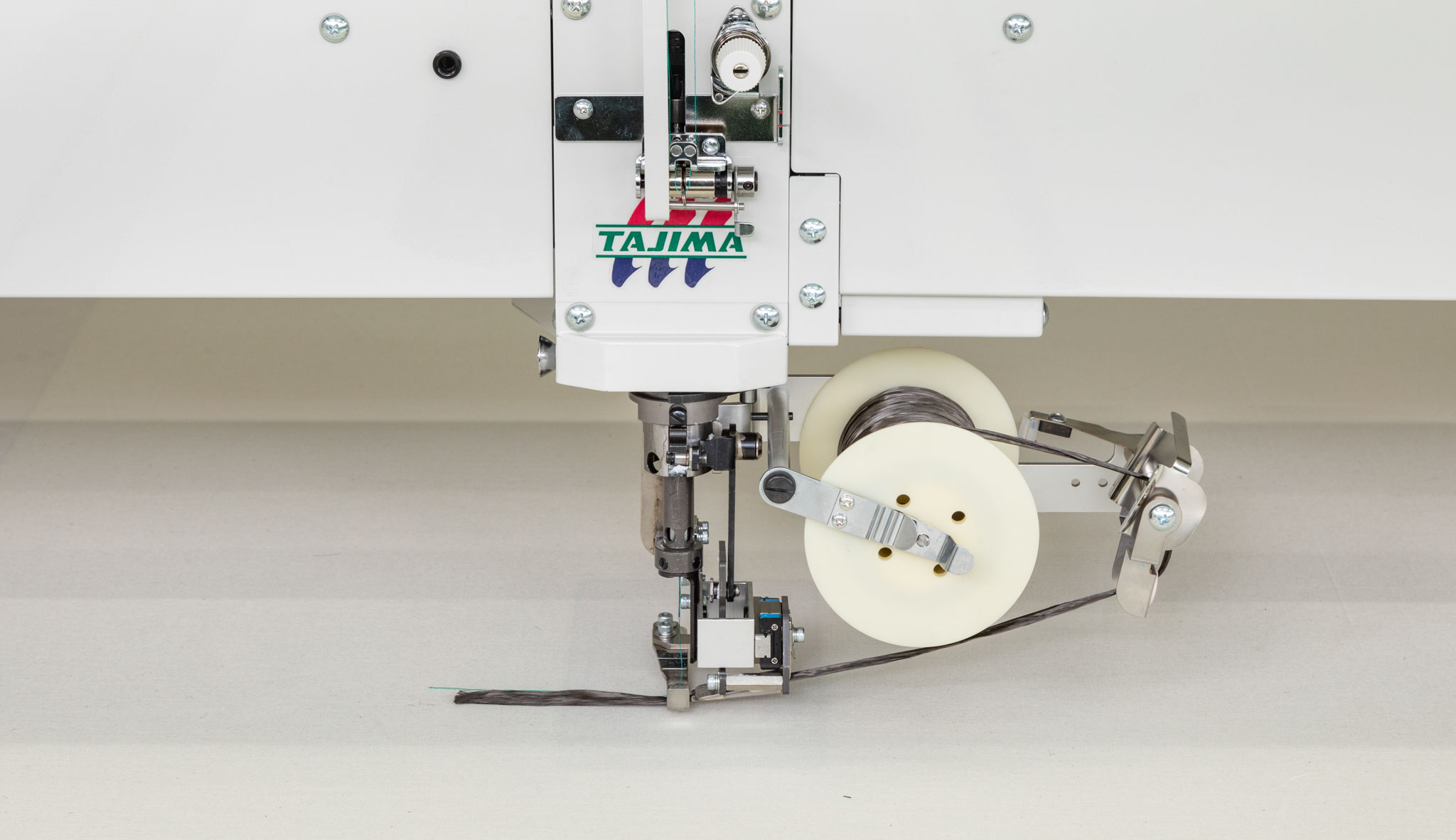

“TCWM” Composite Fiber Sewing Machine

TCWM is a composite fiber sewing machine specifically designed for sewing reinforced fibers. Carbon fiber and other reinforced fibers can be formed into shapes close to that of the finished product, enabling mass production of high-precision preforms with minimal waste. Practical applications continue to expand, with examples including aircraft window frames, stools, brake boosters, and camping goods.

Combines high precision sewing and productivity

Any reinforcing fiber material, of whatever sort—glass fiber, natural fibers, aramid fibers, carbon fiber roving, etc.—is processed at maximum speed. And use of the TFP process, which combines lightness, high strength, cost performance, and environmental performance, permits design orientations that make the most of the material’s capabilities.

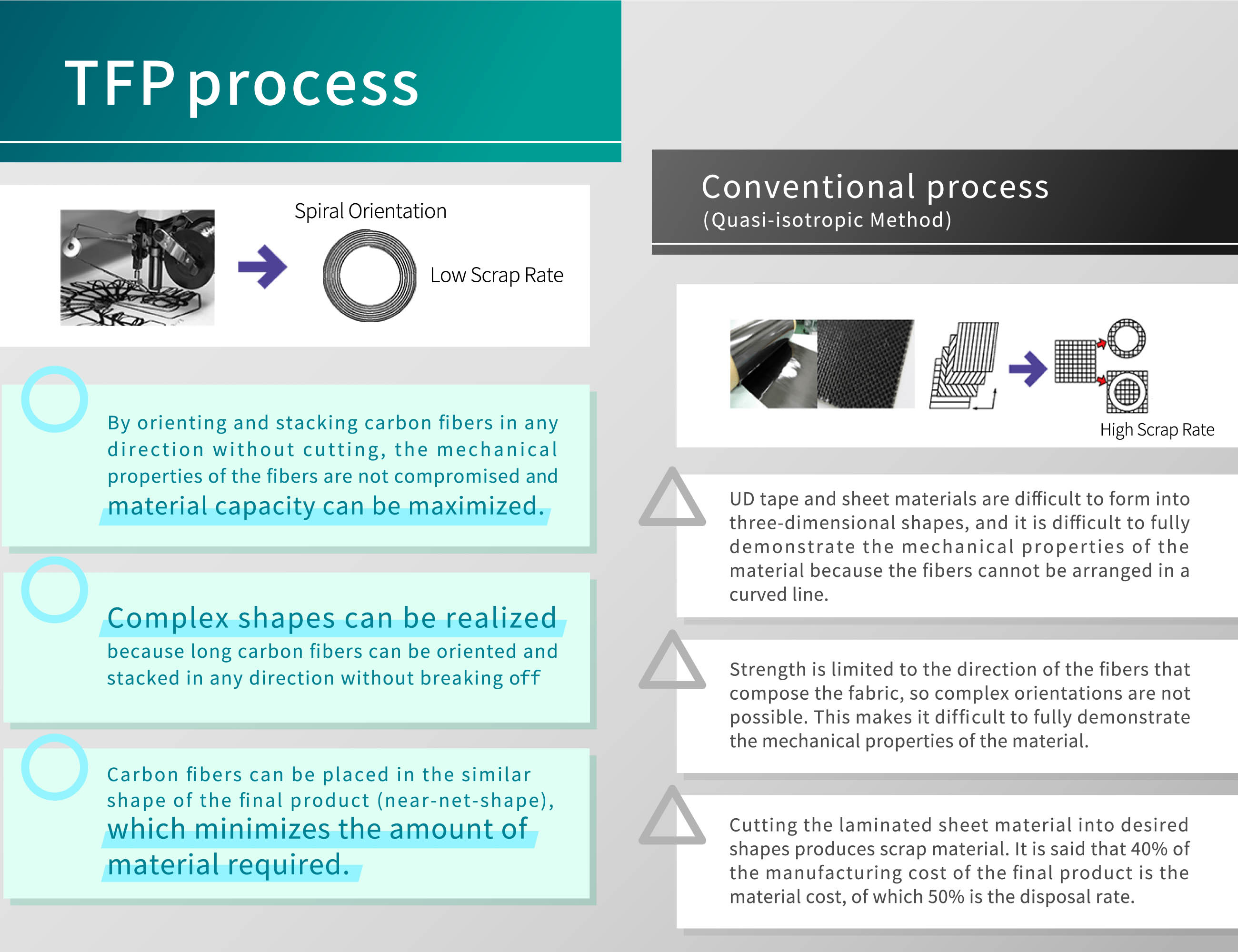

The TFP process, a Modification of the CFRP Concept

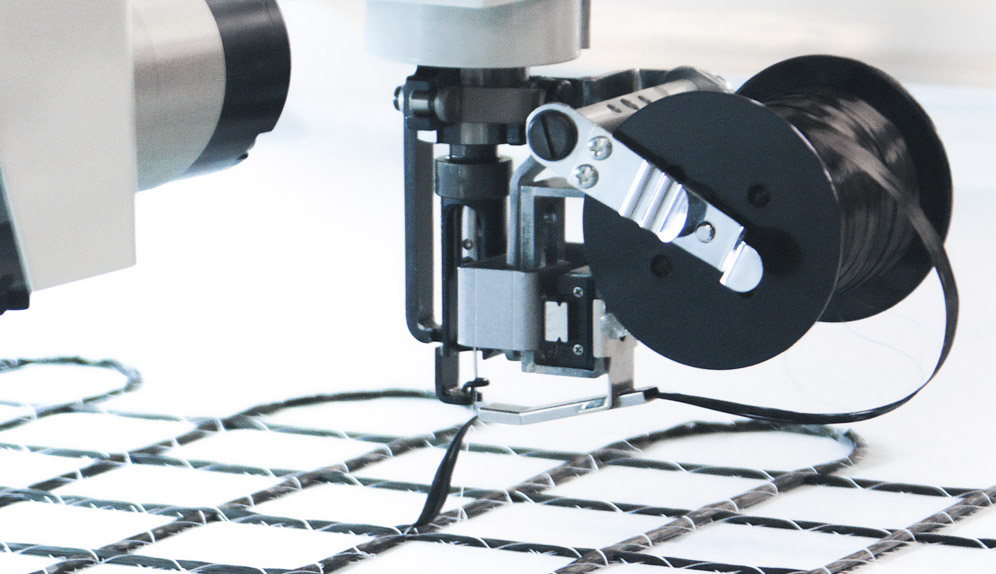

The TFP (Tailored Fiber Placement) process is a process in which reinforcing fibers are sewn onto a base material to form a preform that meets the required properties. Reinforcing fibers such as carbon fibers that exhibit strong anisotropy, which provides strength only in the direction of the fiber’s orientation, can be arranged continuously and freely, making it possible to design a composite material structure that provides the necessary strength in the required direction.

Create More Suitable Stitch Data with “EDOpath 2.0” Software,

Designed for Use with the TFP process

“EDOpath 2.0” is software specifically for the TCWM that controls the precise placement of fiber bundles based on required mechanical properties. This enables the creation of more fitting fiber orientation data and optimal stitch data.

Tajima’s Customer Support Services

Support System Staffed by Specialists

At Tajima Group, our staff of specialists support customers in solving their problems related to the TFP process, including issues with trial production, fiber orientation design, and production of preforms (intermediate base material).

Please feel free to contact us through the CONTACT form.

- Those who want to try the TFP process but do not know where to go for a consultation

- Those facing issues related to durability, weight reduction, and other issues

- Those who want to try new techniques to achieve both functionality and good design

TCWM

TCWM Product Specifications

1~12

Heads

1 or Twin

Needles

520~2,300㎜

Head interval

680/750/800/

1,000/1,500/

2,000/2,500

Depth in Y-axis

1,000rpm

Maximum speed

2.4kw

Power consumption

*Power supply

3-phase 200-220 / 240 / 350 / 380 / 400 / 415 / 440V 50/60Hz

Single-phase 200-240V 50Hz/60Hz

*Stitch length 0.1-12.7mm

*The actual embroidery field and embroidery speed may vary depending on the items being produced, the machine model, and the embroidering conditions.

Manufacturer Options Help Increase Production Efficiency and Safety

Catalog Download

TAJIMAG

Recommended content