“A cut above”

—spaces that stimulate the passenger’s senses

It is said that next-generation mobility is changing the way people travel—and how they stay comfortable—in their cars. It is predicted that the vehicle’s interior space will need to offer the comforts and features as the home or workplace. Tajima applies the embroidery techniques and advanced technologies that we have developed over the years to achieve a combination of superb design and comfort, supporting designers in producing the special spaces that they aim to create.

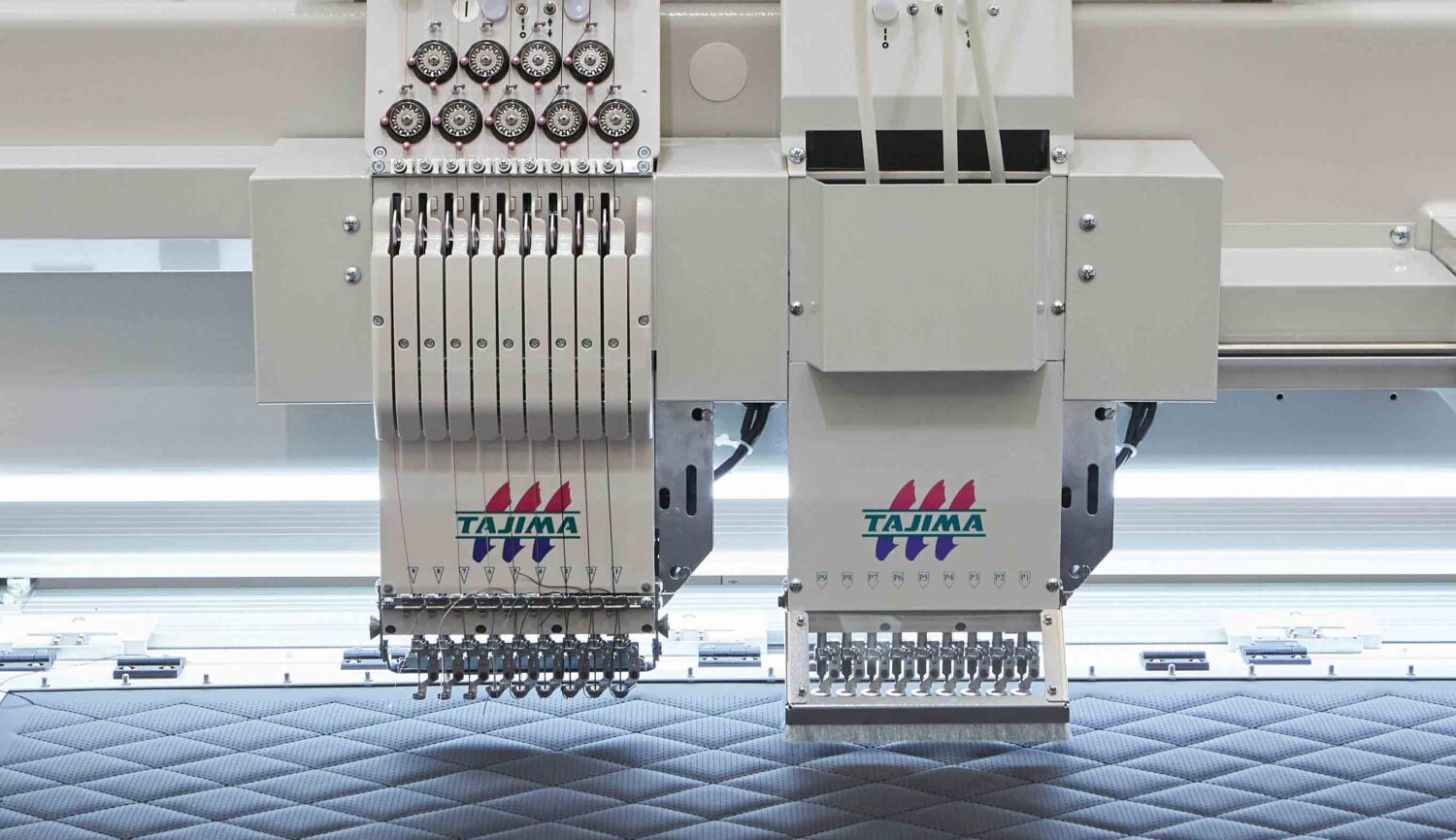

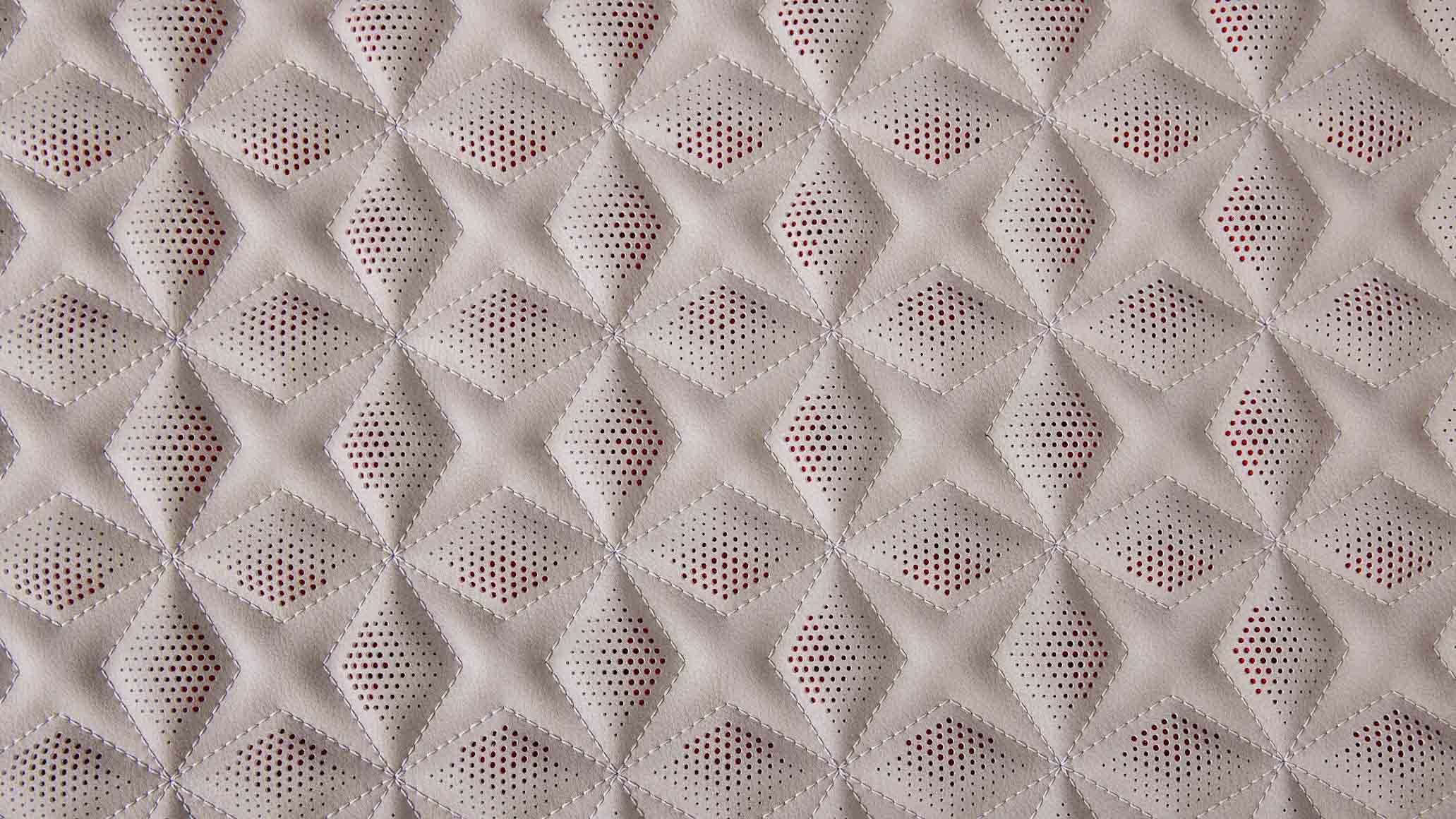

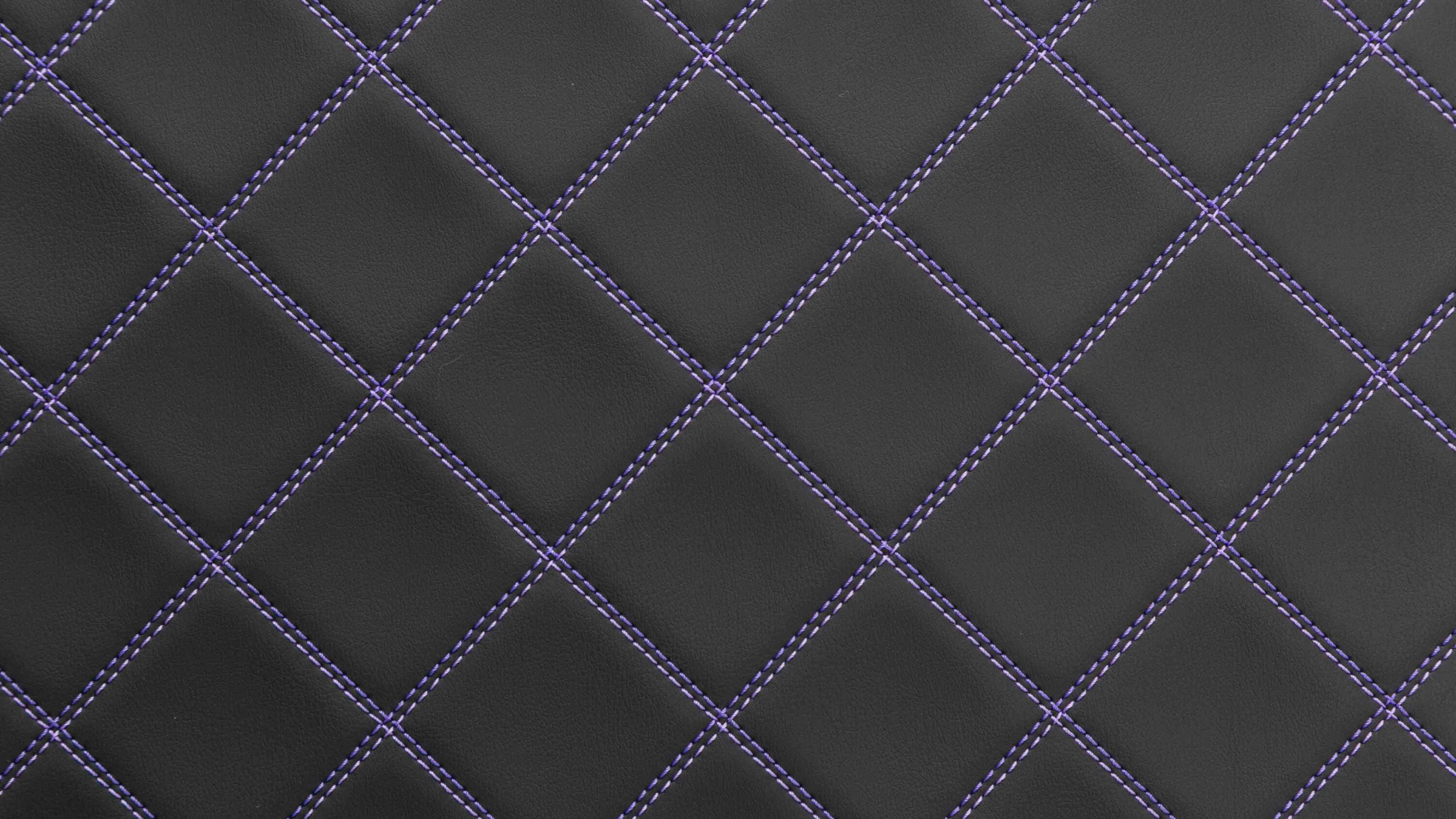

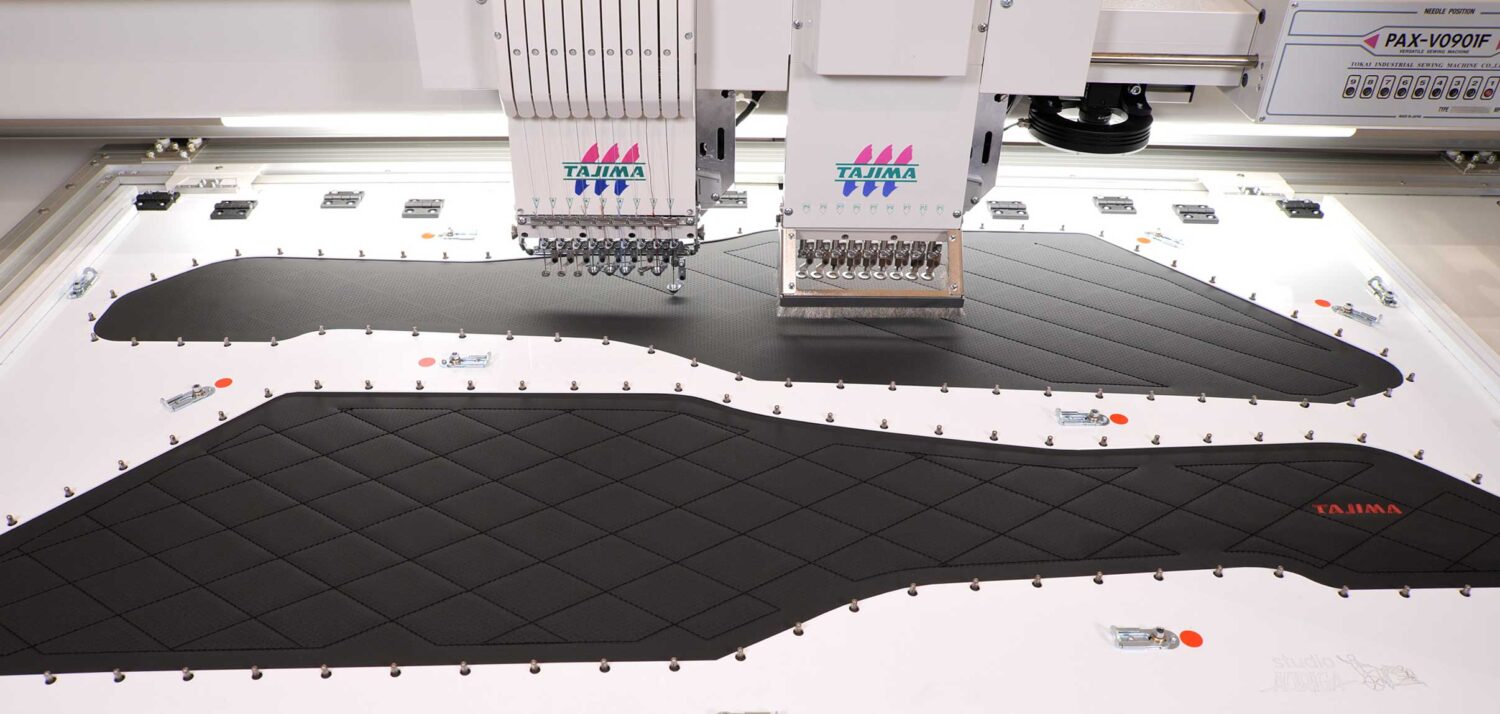

Perforation, multicolor sewing, and multicolor embroidery unites

in creating function and art

PAX enables sewing, embroidery, and perforation on various materials such as synthetic leather, vegan leather, and genuine leather, expanding possibilities not only functionally but also in terms of design, offering more comfortable and beautiful spaces for mobility in cars, RVs, cabin cruisers, and private jets, now and into the future.

More about PAX

TFP process combines design

with the strength and durability of carbon fiber

Many industries in recent years have come to use carbon fiber, leveraging carbon’s properties of strength and lighter weight.

With the use of carbon fiber continuing to grow in the fields of aerospace, industry, sports, and other domains, the Tajima Group now offers process that maximize the properties of carbon fiber and further reduces the material’s weight and increases its rigidity.

Supporting efforts to achieve carbon neutrality

Reinforced fibers have pronounced anisotropic characteristics, i.e., they provide strength only in the fiber’s orientation. This makes it difficult to use conventional process relying on unidirectional tape and sheets in reinforcing hollow, spiral, radial, and other such forms. With Tajima’s TCWM Spec.2 fiber processing machine, a product of our embroidery technology, and the TFP (Tailored Fiber Placement) process developed through academic-industrial alliance, carbon fibers are repeatedly inserted in the areas of the base material where reinforcement is required, thus making possible to provide sufficient strength even for these previously difficult shapes.

We support efforts to achieve carbon neutrality based on processing technology for reinforced fibers that are both light and strong.

Tajima’s Total Solution

to Support Optimal Supply Chain Construction

Supply chain optimization is a critical issue for brands and companies. Nowadays, supply chains must be constructed with geopolitical risks and ethical production/consumption in mind, and Tajima supports the construction of supply chains that best suit the services and values that customers want to provide.

Tajima employs AI, automation, IoT, and other cutting-edge technologies in providing support to production bases on both the hardware and software fronts. In addition, our sales network of more than 60 companies around the world enables us to provide high-quality service anywhere in the world. You can rely on us for everything from installation to maintenance and after-sales support.

Efficient factory operations with PulseID

PulseID is an integrated system that covers everything from automatically creating embroidery data to transferring that data, providing production status, and generating reports. In addition, visualizing the embroidery machines’ operating and production status allows you to evaluate production efficiency.

Cloud technology reduce the costs of adopting the system and allows implementation in the shortest possible time.

Recommended Products

-

Multi-perfect sewing machine

PAX

Perforation, multicolor sewing, and embroidery, all in one machine. Suitable for leather processing.

-

-

Special machine

TCWM

Specialized composite fiber sewing machine for attaching reinforced fibers

-

-

Embroidery Software

PulseID(DG.NET SaaS)

System provides comprehensive support for the embroidery supply chain, from receipt of orders to production

-

Won the “JEC COMPOSITES INNOVATION AWARDS”

The production of a” Monolithic CFRP-Aluminum Monocoque,” which was undertaken by four companies (*) including TISM Co., Ltd. , has won the “JEC COMPOSITES INNOVATION AWARDS AUTOMOTIVE & ROAD TRANSPORTATION-PARTS Category Award.

*Toyota Motor Corporation (Japan), Toyota Central R&D Labs., Inc (Japan), Toyota Customizing & Development Co., Ltd. (Japan), TISM Co., Ltd. (Japan)