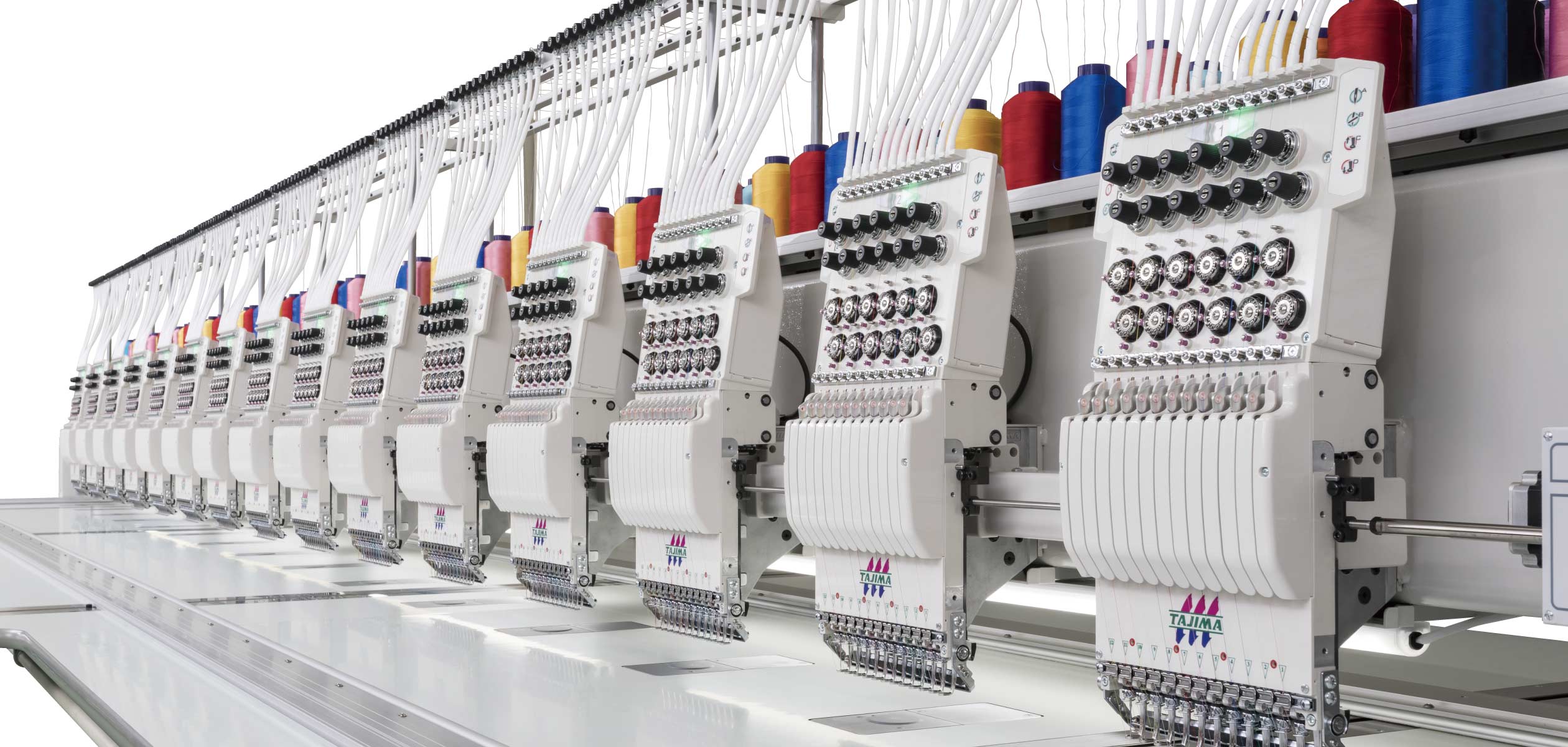

“TMCP-VF” Multi-head Flat Type Standard Model

The TMCP-VF series offers standard multi-head flat type machines with basic functions.

It is suited for factories that embroider on fabrics and parts before sewing, such as large-lot apparel products.

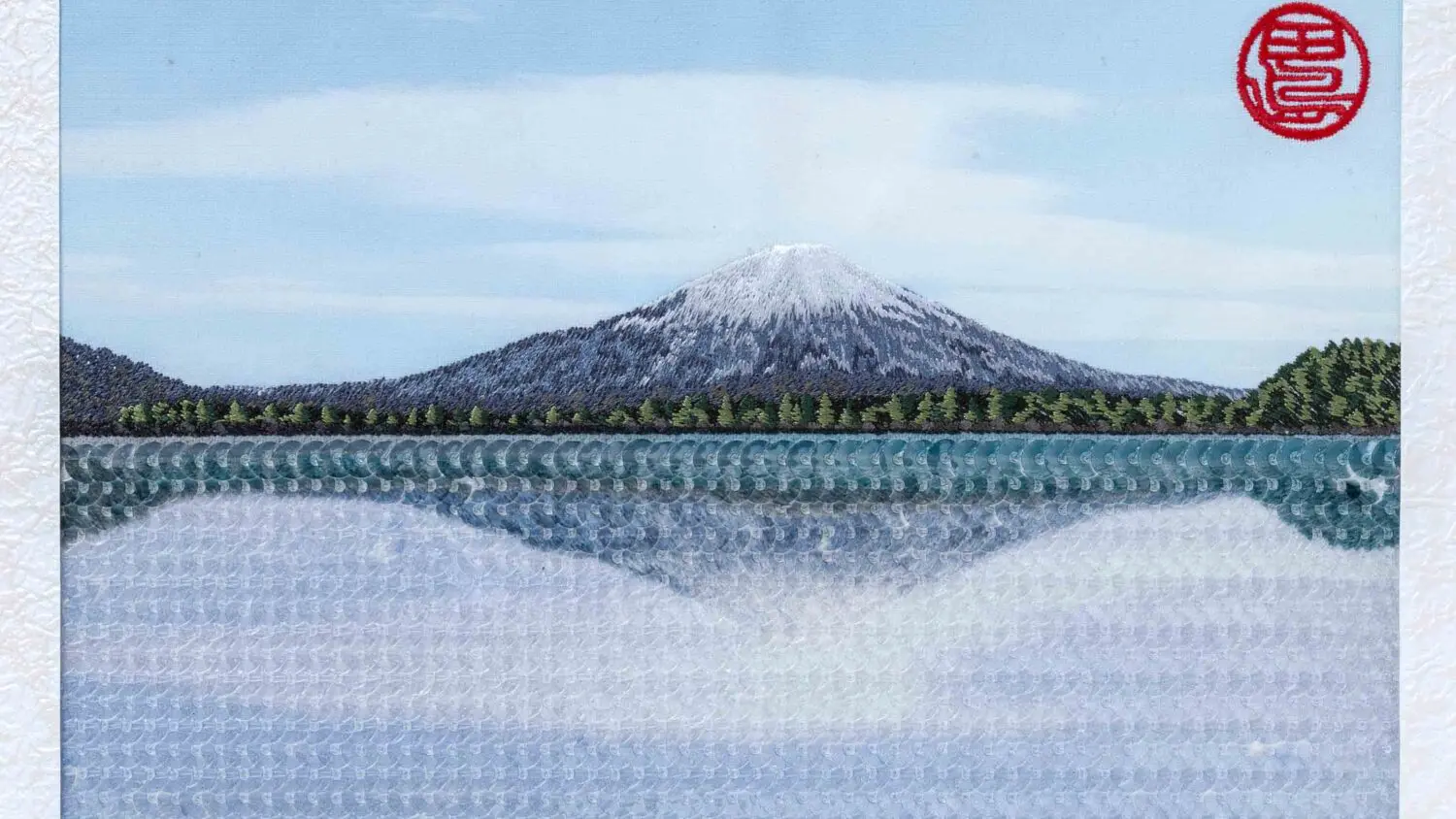

Tajima’s quality recognized by leading brands

It is used by leading brands and fashion houses. They yield a beautiful finish, regardless of whether you are using a satin stitch, a running stitch, or a fill stitch. Beautiful and exquisite embroidery with multi-head technology in which all heads are synchronized.

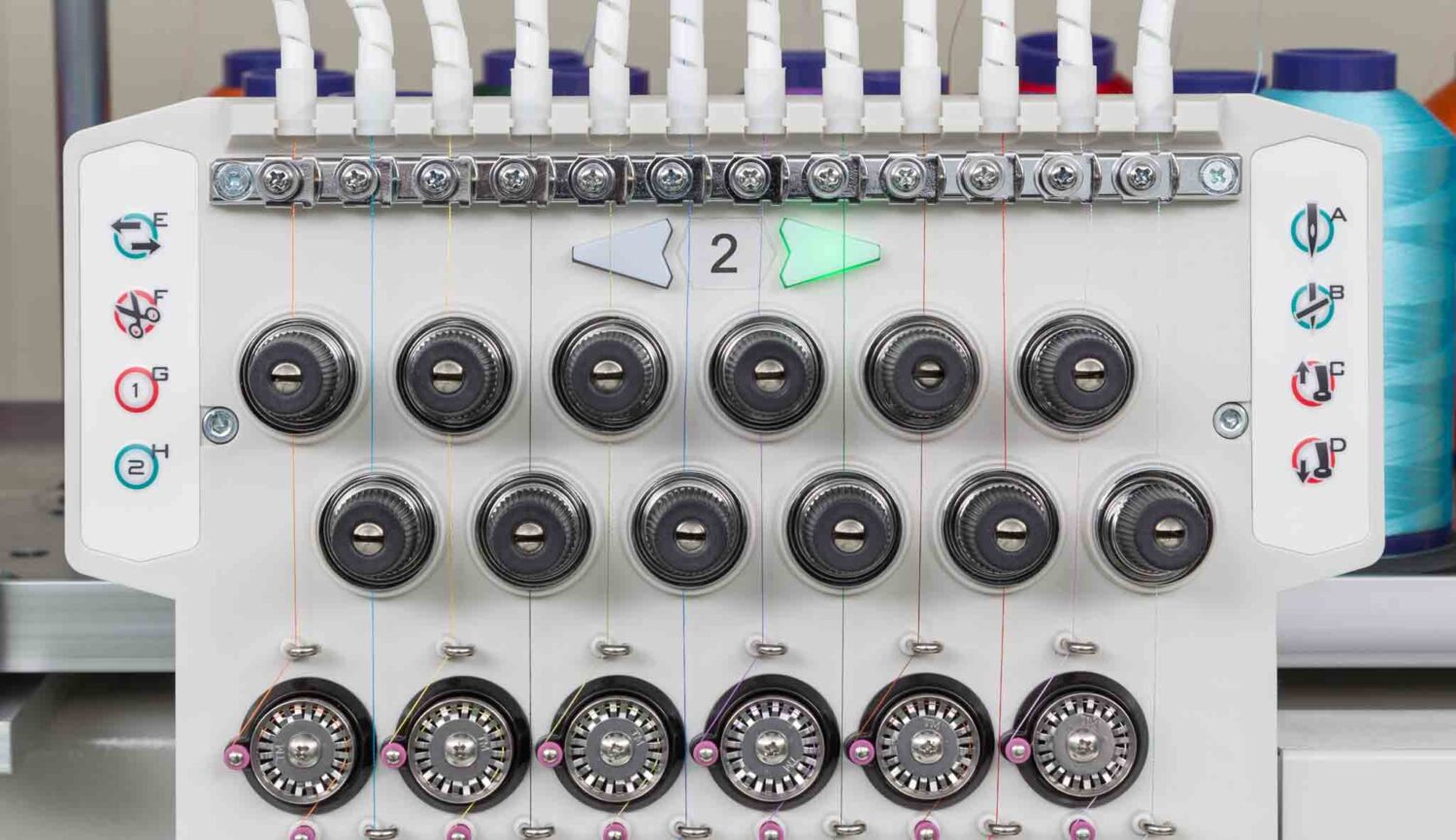

User-Friendly Design

This machine offers a wide variety of operator-friendly functions and options. This reduces operator workload while ensuring high quality embroidery production and smooth machine operation.

Direct Command Switches

Located on the head, these operation switches provide control of the thread trim and other functions on each tension base for increased production efficiency.

Bobbin Changer (Optional)

Up to three bobbins can be pre-staged for replacement. This reduces the work in changing threads makes extended embroidery operations more efficient.

FS Mode

Stabilizes stitching for high-quality embroidery, even with threads that are difficult to work with, such as thicker or loosely twisted threads.

Tajima’s Customer Support Services

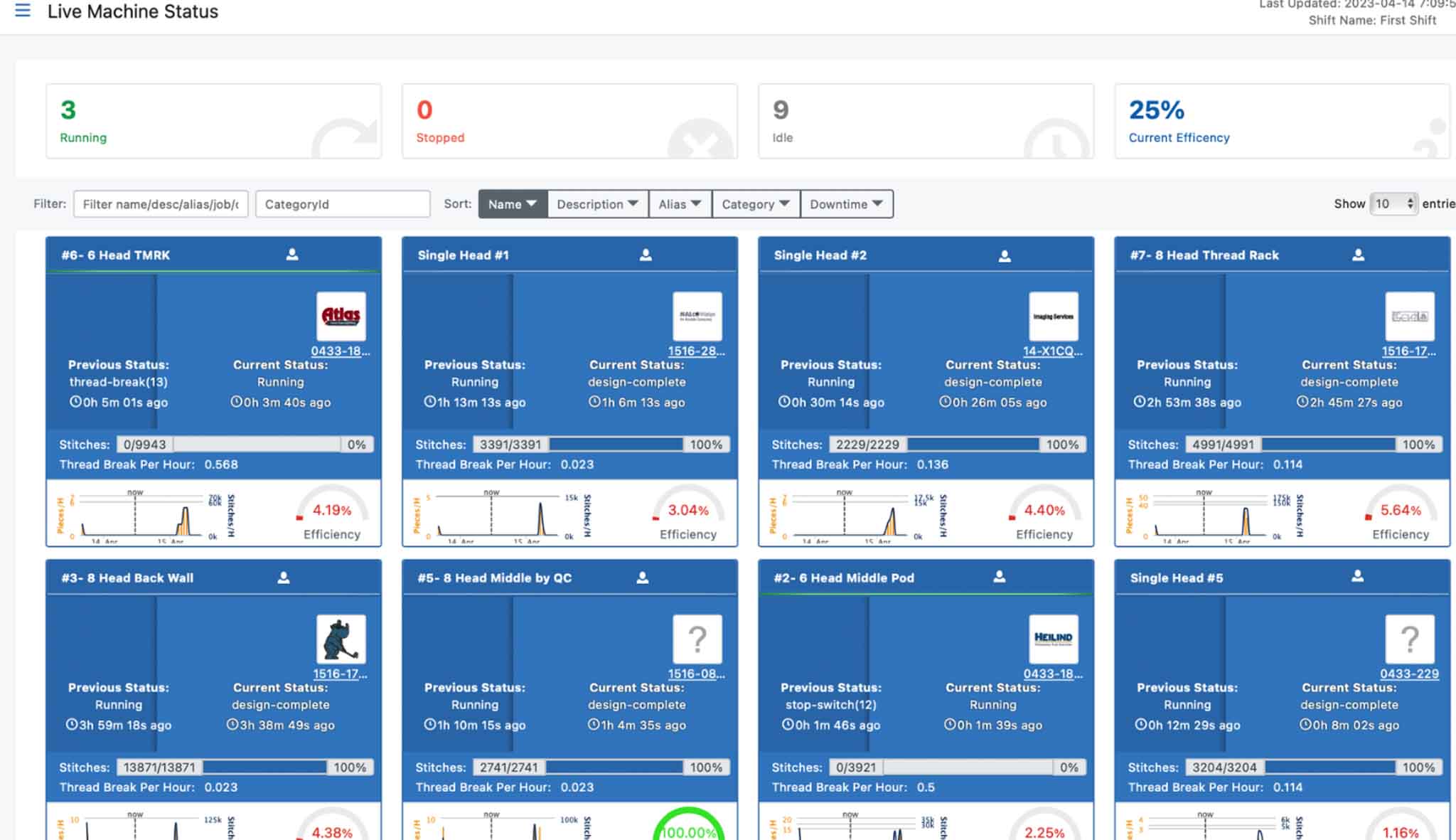

Promoting Digital Technologies at Production Sites

PulseID can be used to centralize management of the operating status of embroidery machines at the production site. Having a software company, Tajima Software Solutions Inc. in the fold as a Tajima Group company, means we can provide both software and hardware support and suggest optimal solutions for each separate issue at production sites.

Sales in 160 countries and regions around the world.

We have delivered machines to 160 countries and regions and have a worldwide service network. Replacing embroidery machines or starting a new embroidery business? We apply Tajima’s proprietary AI technology and software in helping resolve our customers’ business issues. Please feel free to contact us through the CONTACT form.

TMCP-VF

TMCP-VF Product Specifications

4/12/15

18/20

Multi color heads

6/9/12

Needles

200-400㎜

Head interval

1,100rpm

Maximum speed

1.2kw

Power consumption

30㎜

Overlap of heads when using continuous pattern

| Model | Needles | Multi color head |

Head interval | Embroidery field(D×W) | Overall Width | Depth | Height |

|---|---|---|---|---|---|---|---|

| TMCP-V0620FD | 6 | 20 | 200D(W) | 550×200(400) mm 21.6×7.8(15.7) inch |

5,365 mm 211.2 inch |

1,610 mm 63.3 inch |

1,635 mm 64.3 inch |

| TMCP-V0912FS | 9 | 12 | 345S | 680×345 mm 26.7×12.9 inch |

5,455 mm 214.7 inch |

1,820 mm 71.6 inch |

1,635 mm 64.3 inch |

| TMCP-V0918FS | 9 | 18 | 400S | 800×400 mm 26.7×12.9 inch |

8,565 mm 337.2 inch |

2,080 mm 81.8 inch |

1,635 mm 64.3 inch |

| TMCP-V0920FS | 9 | 20 | 330S | 680×330 mm 26.7×12.9 inch |

7,915 mm 311.6 inch |

1,820 mm 71.6 inch |

1,635 mm 64.3 inch |

| TMCP-V1204FS | 12 | 4 | 400S | 680×400 mm 26.7×12.9 inch |

2,865 mm 112.8 inch |

1,820 mm 71.6 inch |

1,535 mm 60.4 inch |

| TMCP-V1212FS | 12 | 12 | 345S | 680×345 mm 26.7×12.9 inch |

5,455 mm 214.7 inch |

1,820 mm 71.6 inch |

1,635 mm 64.3 inch |

| TMCP-V1215FS | 12 | 15 | 400S | 680×400 mm 26.7×12.9 inch |

7,355 mm 289.5 inch |

1,820 mm 71.6 inch |

1,635 mm 64.3 inch |

*Power supply

3-phase 200 – 240 / 380 / 415V 50/60Hz

Single-phase 200 – 240V 50/60Hz

*Contact us for other specifications and more details.

*The actual embroidery field and embroidery speed may vary depending on the items being produced, the machine model, and the embroidering conditions.

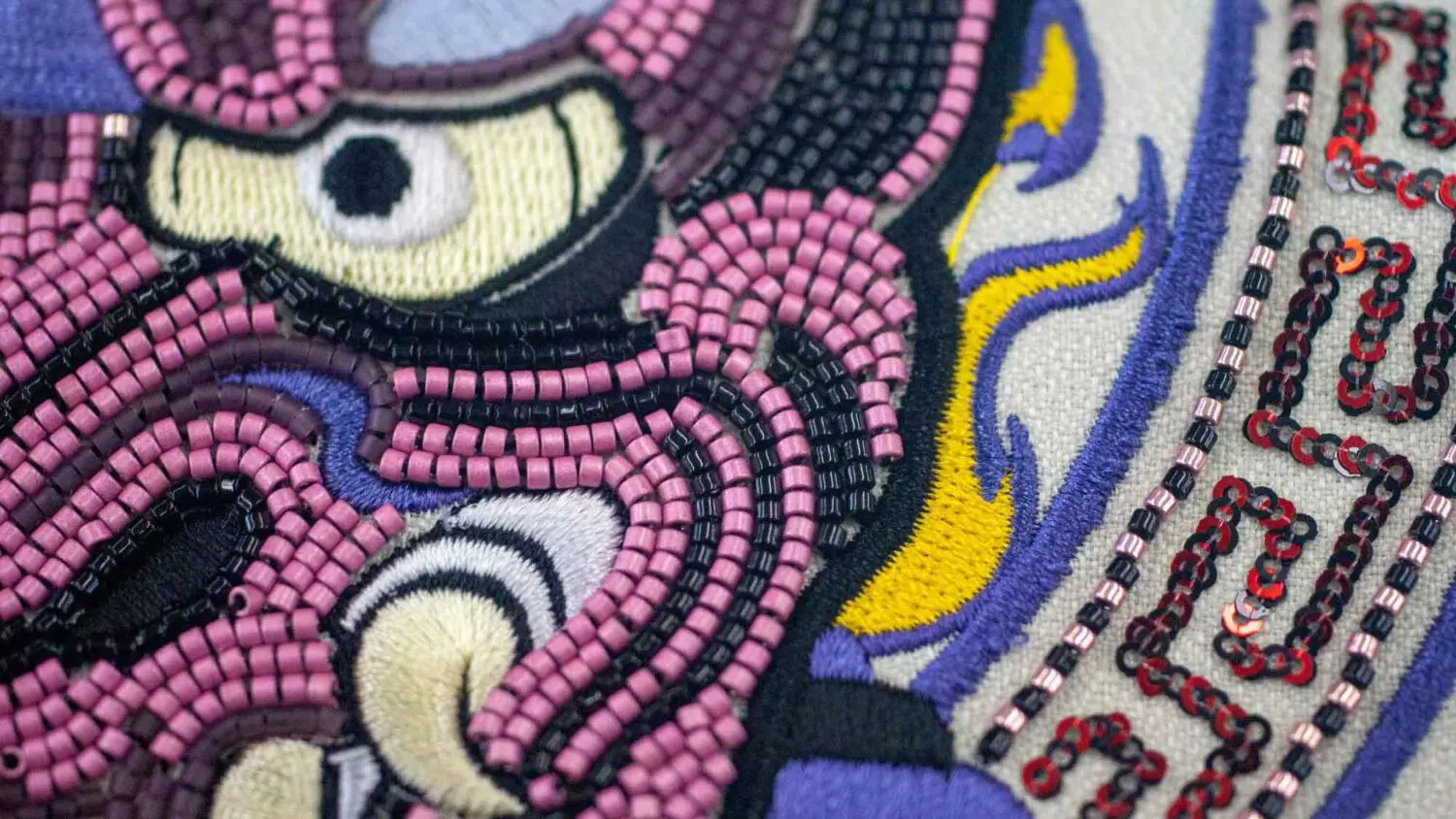

Factory options support a wider variety of embroidery expression and increase production efficiency

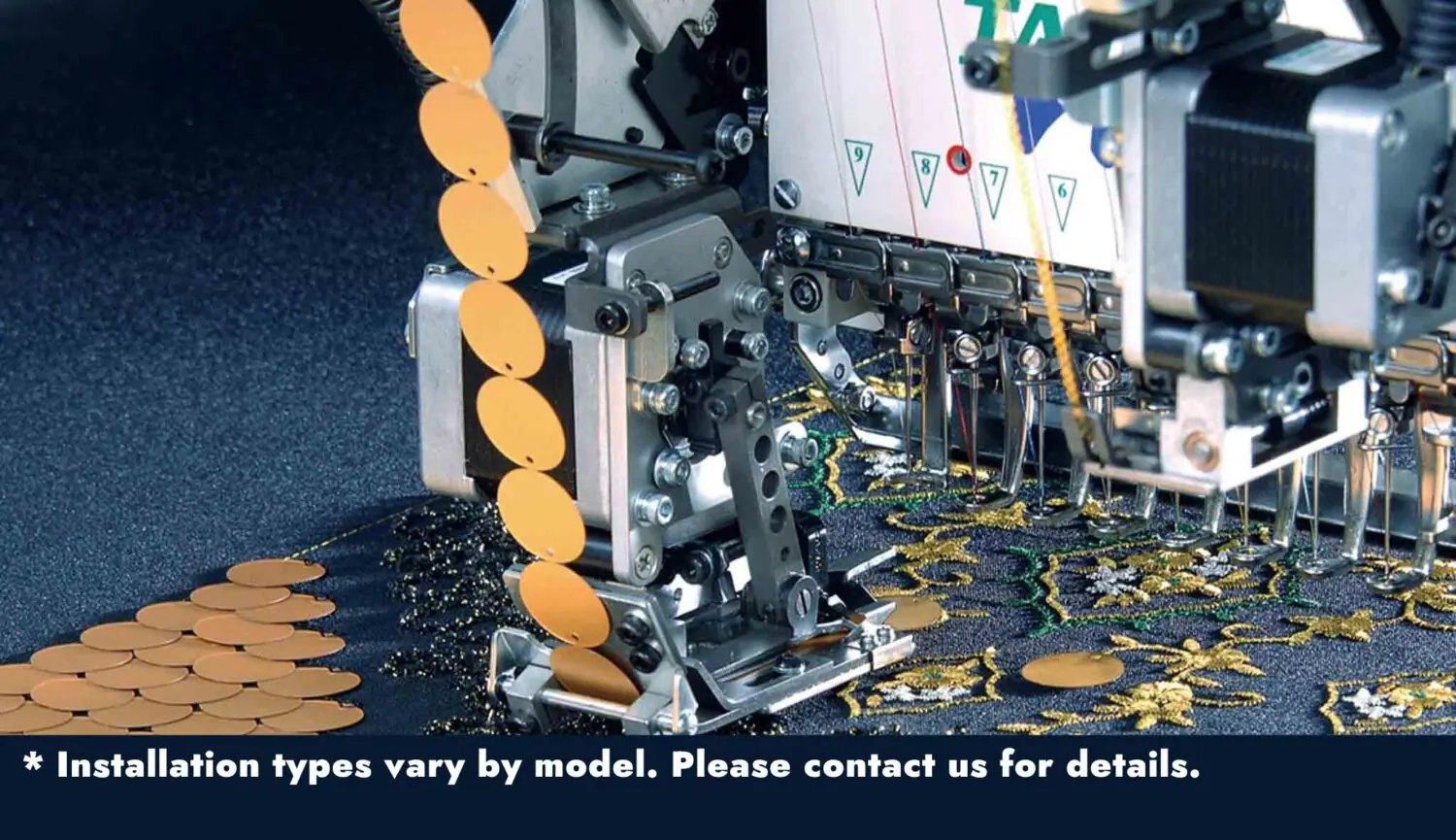

Sequin Device

Seed Beads Device

Bobbin Changer

Position Marker

AFC

Embroidery frame that can be applied to various items

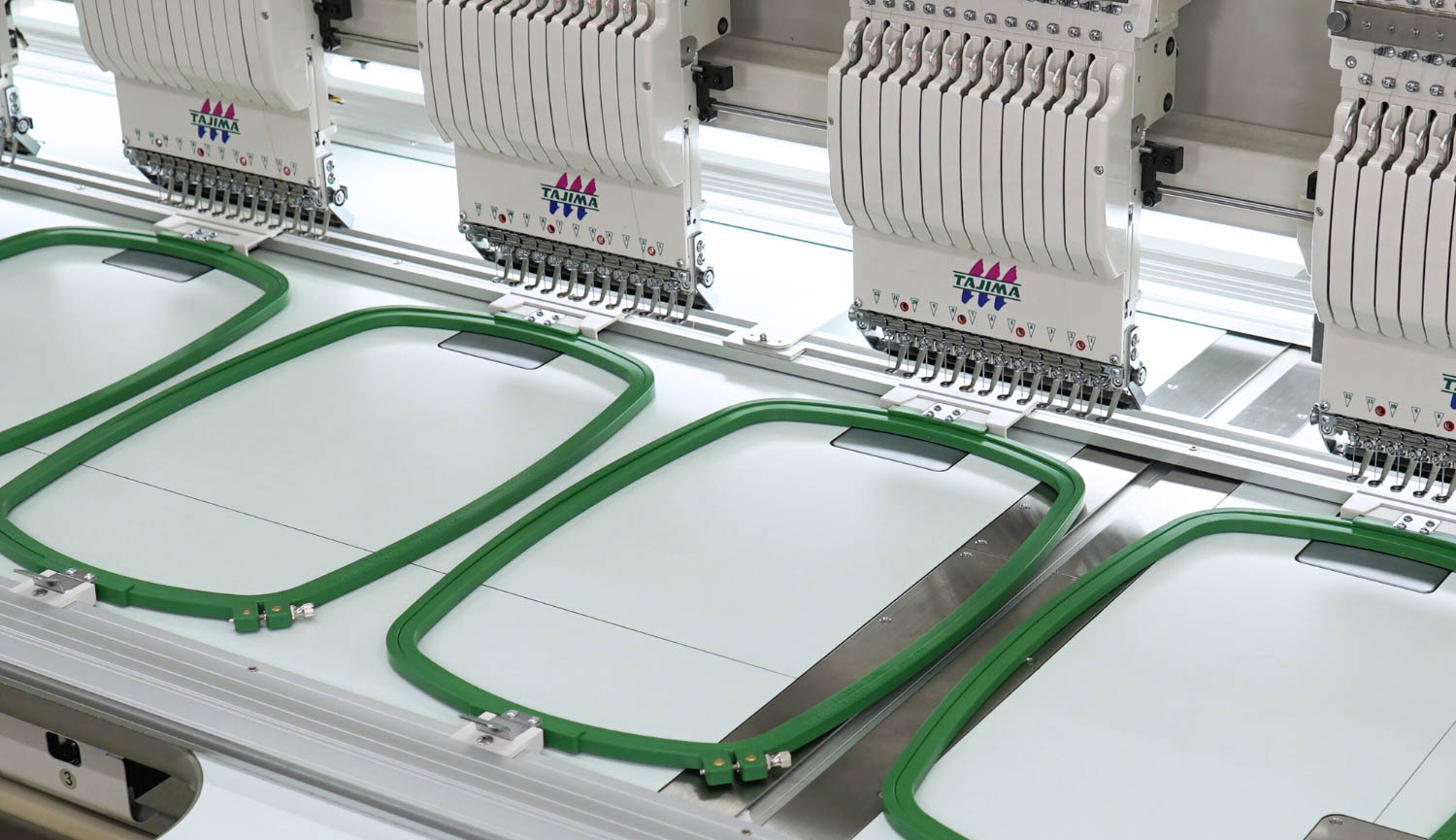

Border frame

OFAM(One-touch frame)

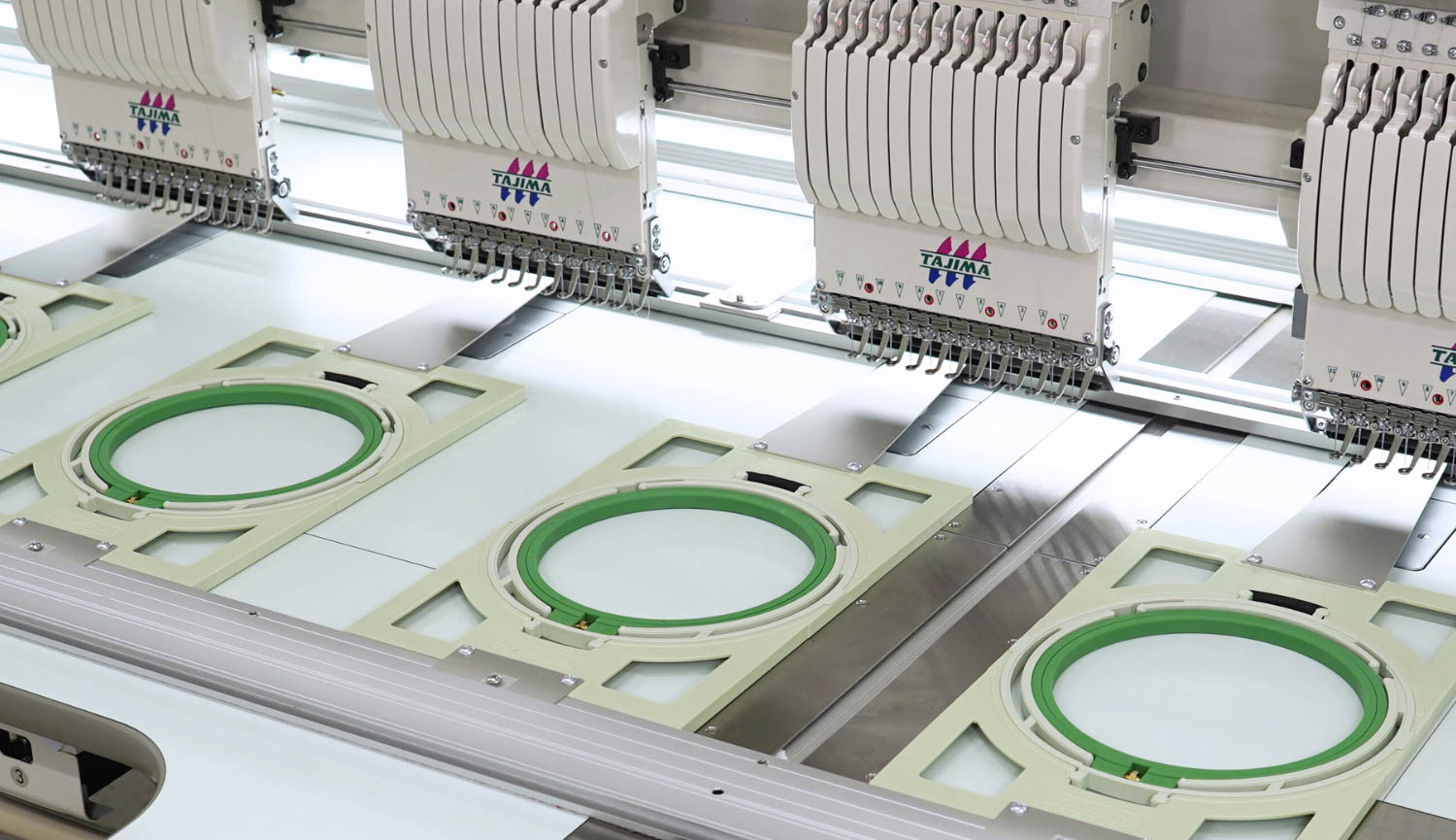

Aluminum square frame

Spider net frame

Catalog Download

Distributors

TAJIMAG

Recommended content

-

Dialogue・Special feature

Tabio Co., Ltd. | Creating new value through embroidery. Producing one-of-a-kind socks, unique in all the world.

-

Dialogue・Special feature

Kasamori Corporation | Challenge yourself to do what you couldn’t before. Keep at it, and embroidery will have a bright future.

-

Customer’s voice

Kasamori Corporation | Enhancing Daily Life Through Embroidery. The Story of Developing a New Brand by Kasamori Corporation.